pg. 17

A flue outlet for the evacuation of combustion products into the atmosphere must satisfy the following requirements :

-be sealed against the penetration of combustion products, watertight and thermally insulated:

-be made from materials capable of resisting normal mechanical stress, heat and the action of the combustion products and condensate

produced by them over long periods of time;

-have vertical runs and be completely free of any narrow sections along its entire length;

-be kept clean at all times as soot or unburnt oil deposits reduce its section and could, if the deposits are large, catch fire inside the flue outlet;

be suitably insulated to avoid phenomena of condensate or cooling of tubes, particularly if located on the external wall of a building;

-be at a suitable distance from combustible or easily inflammable materials separated by means of an air gap or insulation;

-have a clean out chamber for the collection of solid materials and condensate below the first smoke pipe. Access to this chamber must be

possible by means of an opening fitted with an airtight metal door.

-have a circular, square or rectangular internal section: in the latter two the corners must be rounded with a radius measuring a minimum of 20mm;

-have an internal section that is slightly larger than the section of the appliance exhaust pipe; in any case, have the following minimum sections:

for a height of up to 5m

600cm²

for a height between 5 and 7m

400cm²

for a height greater than 7m

300cm²

If the section is too small it reduces the flue outlet draft. If the section is too big it can cause inadequate draft if the section is not insulated.

Whereas if it is well-insulated it can increase the draft.

-be at least 4m from the floor on which the appliance is installed;

-be fitted at the top with a cap that fulfils definite requirements;

-must not be installed in inhabited locations as the flue outlet is always slightly more pressurised that its surroundings.

If you use a large pre-existing chimney, you can adapt it by installing a stainless steel chimney liner, then filling in the spaces between the liner

and the chimney with insulating material.

7 . 1

7 . 1

7 . 1

7 . 1

7 . 1

G E N E R A L .

G E N E R A L .

G E N E R A L .

G E N E R A L .

G E N E R A L .

Due to the frequent accidents caused by poor functioning of flue outlets installed in private dwellings, we have prepared the following paragraph

to assist the installer in his inspection of the parts concerned with eliminating the gases produced by combustion. The smoke exhaust pipe must

be installed according to UNI 7129/92 and UNI 10683/98.

7

7

7

7

7

SMOKE EXHAUST TUBE

SMOKE EXHAUST TUBE

SMOKE EXHAUST TUBE

SMOKE EXHAUST TUBE

SMOKE EXHAUST TUBE

7 . 1 . 1

7 . 1 . 1

7 . 1 . 1

7 . 1 . 1

7 . 1 . 1

CONNECTION TO THE

CONNECTION TO THE

CONNECTION TO THE

CONNECTION TO THE

CONNECTION TO THE

C H I M N E Y

C H I M N E Y

C H I M N E Y

C H I M N E Y

C H I M N E Y

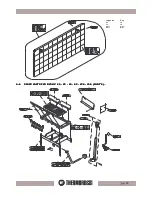

The smoke outlet can be connected at the top of the

plate or at the back of the central heating cooker using

the hardware provided as illustrated in the figure on the

right. If you wish to connect the chimney to the back of

the heater then you need to close the top smoke outlet

with the cover provided, remove the perforated cover

from the back and remove the fixed cover by undoing

the screws. Next connect the cast iron flue collar using

the hardware provided. There must be no narrowing of

the pipes that connect the central heating cooker to the

flue outlet. The joints must be completely airtight. The

number of elbows used must be kept to a minimum.

Horizontal runs must be kept to a minimum and have a

minimum slope of 4%. Never use the same flue outlet for

more than one appliance.

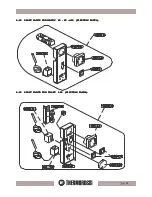

VITE TC+ M6

DADO M6

K

RONDELLA d. 6

Key

screw

nut

washer

Legenda

vite

dado

rondella