45

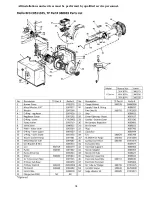

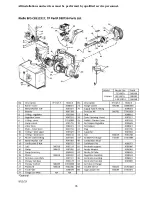

All installations and services must be performed by qualified service personnel.

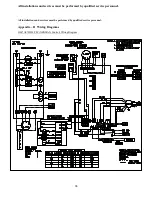

ALTERATIONS REQ’D FOR A/C @ DESIGN EXTERNAL STATIC PRESSURE

COOLING UNIT

HTG Speed by Input

Low Mid High

Fire Fire Fire

Recommended CLG Speed

36,000

LOW

MED

MH

LOW

42,000

LOW

MED

MH

MED LOW

48,000

LOW

MED

MH

MED HIGH

AS SHIPPED CLG.

60,000

LOW

MED

MH

HIGH

Speed Tap\ Static Pressure

Furnace Airflow (CFM) vs. External Static pressure (in. WC.)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Low

1454

1392

1321

1255

1158

1074

932

ML

1620

1567

1499

1413

1349

1282

1202

Med

1674

1613

1560

1502

1429

1370

1287

MH

1778

1737

1666

1613

1551

1487

1417

High

2148

2091

2029

1973

1928

1884

1834

Furnace Motor Current Draw (Amps/Watts) vs. External Static pressure (in. WC.)

Low

3.4

266

3.6

280

3.7

292

3.9

306

4.0

321

4.2

331

4.3

344

ML

4.4

351

4.6

366

4.7

381

4.9

399

5.1

413

5.2

424

5.3

435

Med

4.9

400

5.1

416

5.3

429

5.4

445

5.6

462

5.8

471

5.9

485

MH

5.8

475

5.9

486

6.1

502

6.2

518

6.5

537

6.6

553

6.8

565

High

9.3

806

9.4

815

9.6

837

9.8

855

10.0

874

10.2

891

10.4

912

Speed Tap\ Static Pressure

High Fire Temperature Rise vs. External Static pressure (in. WC.)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Low

84

88

93

98

106

114

132

ML

76

78

82

87

91

96

102

Med

73

76

79

82

86

90

95

MH

69

71

74

76

79

83

87

High

57

59

61

62

64

65

67

Speed Tap\ Static Pressure

Mid Fire Temperature Rise vs. External Static pressure (in. WC.)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Low

76

79

83

88

95

103

118

ML

68

70

73

78

82

86

92

AS SHIPPED HTG.

Med

66

68

71

73

77

80

86

MH

62

63

66

68

71

74

78

High

51

53

54

56

57

58

60

Speed Tap\ Static Pressure

Low Fire Temperature Rise vs. External Static pressure (in. WC.)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Low

64

67

71

75

81

87

101

ML

58

60

62

66

69

73

78

Med

56

58

60

62

66

68

73

MH

53

54

56

58

60

63

66

High

44

45

46

47

49

50

51

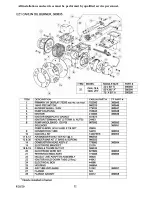

OL8FA119T60

Содержание OL6FA072D48B

Страница 2: ......

Страница 27: ...23 All installations and services must be performed by qualified service personnel...

Страница 29: ...25 All installations and services must be performed by qualified service personnel...

Страница 31: ...27 All installations and services must be performed by qualified service personnel...

Страница 33: ...29 All installations and services must be performed by qualified service personnel...

Страница 34: ...30 All installations and services must be performed by qualified service personnel...

Страница 35: ...31 All installations and services must be performed by qualified service personnel...

Страница 36: ...32 All installations and services must be performed by qualified service personnel...

Страница 37: ...33 All installations and services must be performed by qualified service personnel 57...

Страница 38: ...34 All installations and services must be performed by qualified service personnel...

Страница 39: ...35 All installations and services must be performed by qualified service personnel...

Страница 50: ...46 All installations and services must be performed by qualified service personnel OL8RA119T60...