All installations and services must be performed by qualified service personnel.

26

2.

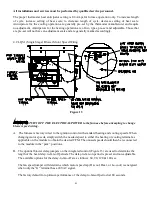

Connecting The Exhaust Vent To The Inducer

a.

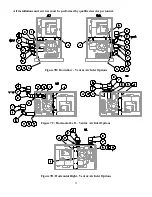

The Exhaust Vent piping may exit the furnace thru either of several locations as depicted in

Figures 7A-D. Upon selection of the location to exit the furnace, cut out the appropriate

knock-out and install the rubber grommet provided. The grommet should be installed from the

inside so that the insulation is captured between the flange of the grommet and the metal

panel. All PVC connections inside the cabinet should be sealed with silicone caulk to enable

easy disassembly for future repairs.

b.

If the Vent is going through the Top panel in an Upflow configuration, connect a 2-inch 90°

PVC street elbow to the flexible drain adapter already installed on the inducer blower. Tilt the

street elbow so it is installed at a 45° angle from the vertical. Tighten the worm clamp on the

flexible drain adapter to seal and hold the elbow in place. Then connect a 2-inch 45° PVC

street elbow to the previously installed elbow so that it points up toward the top panel. Now a

section of 2-inch PVC pipe can be installed through the rubber grommet in the top panel into

the 45° street elbow. A similar configuration may be used with a Horizontal Left

configuration to allow the flue to exit the cabinet toward the side.

c.

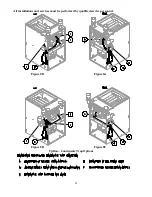

If the Vent is going thru the Left side panel of an Upflow configuration, remove the Door

Latch Channel and its 4 screws. Then remove the Inducer Blower and the 4 nuts & washers

which attach it. The Inducer Blower should then be rotated 180° and re-installed. Do not

over-tighten the 4 nuts which attach the inducer, as that may cause the inducer’s internal

blower wheel to rub. Replace the 5/16” ID tubing which ran from the inducer to the pressure

switch. Now re-install the Door Latch Channel and its mounting screws. The flexible drain

adapter that was factory installed on the exit of the inducer must be retained at the exit of the

inducer. Now a section of 2-inch PVC pipe can be installed through the rubber grommet in the

left panel into the flexible drain adapter. Tighten the worm clamp on the flexible drain adapter

to seal and hold the PVC pipe in place. Rotation of the inducer is similar in Downflow and

Horizontal configurations, if it is necessary to redirect the flue piping.

NOTICE:

The flexible drain adapter has an arrow indicating the direction of flow. It must be

installed with the arrow pointing toward the PVC pipe for the drain function to work properly.

d.

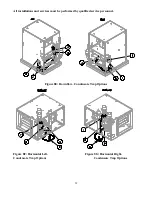

If the Vent is going thru the Right side panel of an Upflow configuration, merely install a

section of 2-inch PVC pipe through the rubber grommet in the right panel into the flexible

drain adapter. Tighten the worm clamp on the flexible drain adapter to seal and hold the PVC

pipe in place. Connection is similar in Downflow or Horizontal configurations

3.

Connecting The Combustion Air Intake Piping

: Outside combustion air must NOT be drawn from an area directly adjacent to a

pool, hot tub or spa. Measures should be taken to prevent the entry of corrosive chemicals or

vapors into the combustion air supply. Such chemicals include but are not limited to

chlorinated and/or fluorinated hydrocarbons such as found in refrigerants, aerosol

propellants, dry cleaning fluids, degreasers , bleaches, air fresheners or solvents. Vapors from

such products can form reactive acid producing chemical species when burned in a gas flame.

Содержание CLQS1-050T36N

Страница 2: ......

Страница 4: ......

Страница 47: ...All installations and services must be performed by qualified service personnel 45...

Страница 55: ...All installations and services must be performed by qualified service personnel 53...

Страница 56: ...All installations and services must be performed by qualified service personnel 54...

Страница 57: ...All installations and services must be performed by qualified service personnel 55...

Страница 59: ...All installations and services must be performed by qualified service personnel 57...

Страница 60: ...All installations and services must be performed by qualified service personnel 58...