All installations and services must be performed by qualified service personnel.

35

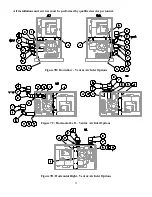

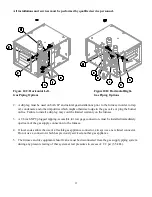

Figure 10C: Horizontal Left–

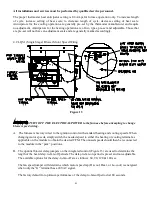

Figure 10D: Horizontal Right-

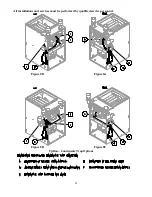

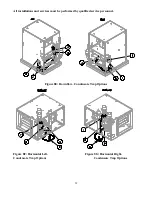

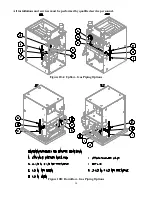

Gas Piping Options

Gas Piping Options

2.

A drip leg must be used on both LP and natural gas installations prior to the furnace in order to trap

oil, condensate and other impurities which might otherwise lodge in the gas valve or plug the burner

orifice. Failure to install a drip leg may void the limited warranty on the furnace.

3.

A 1/8 inch NPT plugged tapping, accessible for test gage connection, must be installed immediately

upstream of the gas supply connection to the furnace.

4.

If local codes allow the use of a flexible gas appliance connector, always use a new listed connector.

Do not use a connector which has previously serviced another gas appliance.

5.

The furnace and its equipment shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa).

Содержание CLQS1-050T36N

Страница 2: ......

Страница 4: ......

Страница 47: ...All installations and services must be performed by qualified service personnel 45...

Страница 55: ...All installations and services must be performed by qualified service personnel 53...

Страница 56: ...All installations and services must be performed by qualified service personnel 54...

Страница 57: ...All installations and services must be performed by qualified service personnel 55...

Страница 59: ...All installations and services must be performed by qualified service personnel 57...

Страница 60: ...All installations and services must be performed by qualified service personnel 58...