ISU-689:2016/GB

6

3.4. Connection to the gas installation

All connections should be made by an appropriately

qualified person, in accordance with applicable standards

and regulations, in particular those relating to safety.

Connect a gas supply pipe directly to the connector of the boiler gas

unit by means of standard connector subassembly. It is necessary to

install a gas filter on the gas supply pipe. This filter is not included in

the standard boiler equipment. The gas filter is necessary for a

proper operation of a gas unit and a burner. Install a cut-off valve on

the gas pipe in an accessible place.

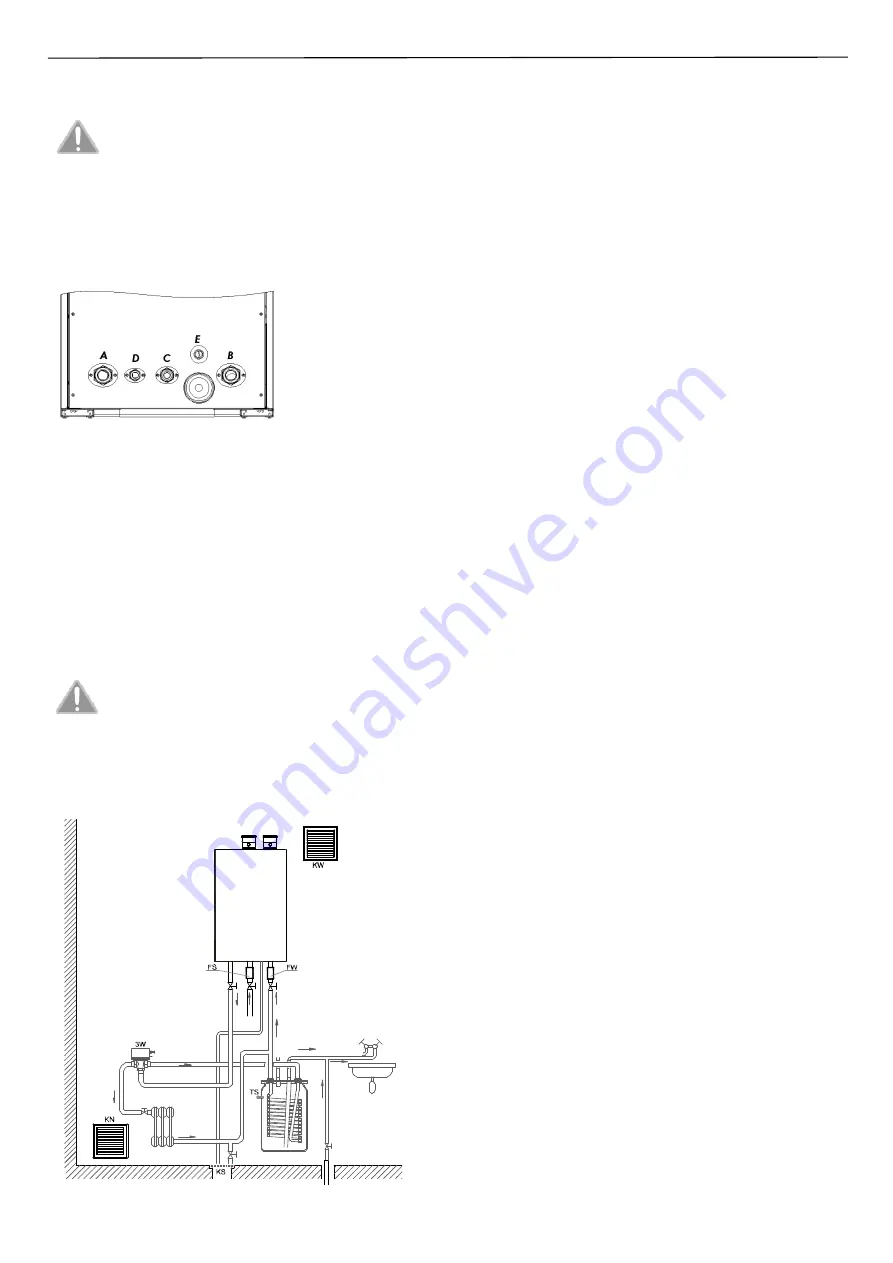

A - (

G5/4”

)

–

Power supply of the CH

installation

B

–

(G5/4”)

–

return from the CH

installation

C

–

(G1”)

–

Gas connection

D

–

(G3/4”)

- Drain from the safety

valve / emptying the boiler

E

–

(

Ø

25)

- Condensate drain

Fig. 3.4.1

–

Description of the connectors

3.5. Connection of the boiler to a water system

Power connector and connector of return of the central heating

boiler should be screwed to the installation. Install a water filter on a

water return from central heating system (in front of the connection

with the pump). The filter is not included in standard boiler

equipment. The central heating system should be thoroughly rinsed

out before the boiler is connected. In the central heating system it is

permitted to use as a heat carrier any antifreeze fluids which can be

used in central heating systems.

The cut-off valves needs to be installed between the boiler and

central heating system so that the boiler could be dismounted

without draining the system.

Before installing the boiler thoroughly flush the central

heating system to free it from any solid impurities.

It is recommended that after first start-up of the boiler

and heating up of the installation drain the water from

the system to remove residues of pastes metallurgical

and precautionary measures of heaters. These activities

would benefit for the operation of the device, its

parameters and components life.

Fig. 3.5.1

–

Installation requirements

KW

–

Exhaust ventilation,

KN

–

Air inlet,

3W

–

three-way valve,

TS

–

Tank temp.

sensor,

KS

–

Floor drain,

FW

–

Water filter,

FS

–

gas filter.

After the boiler installation it is necessary to:

•

Fill the heating system with water. Filling the system should be

done slowly to allow the air outflow through the air vent valve

mounted in the boiler; also check the complete air outlet from all

components of the system.

The pressure in the cold installation

should be 1.2 ÷ 1.5 bar.

•

Check whether connections of the boiler and in the central heating

system are tight.

•

Ensure that pipes of water and heating installation are not used as

grounding the electrical installation.

•

Connect the outlet of safety valves to the floor drain to avoid

flooding the room (where the boiler is installed) as a result of

protection devices. Such outlets should be carried out so as to

avoid damage in the case of opening of the valve and outflowing of

the hot fluid.

3.5.2. Cleaning the installation and water treatment for

filling the CH installation

In all elements of the CH installation there are processes of scaling,

corrosion and similar phenomena. The boiler is the most expensive

part of the installation and it is important to ensure that the heat

exchanger and other components are protected against these

processes. Correct preparation of the CH system for the operation

shall be carried out by two operation: cleaning the installation and

water treatment for the operation of the installation.

Cleaning the installation

In new installation there may be remnants of the installation such as

solder residues, welding residues, flux residues, oil residues, grease

residues, or corrosion products - especially in old installation. In the

first place, both new and old installations should be cleaned with

clean water to remove solid waste. his operation must be carried out

without the boiler installed. The next step is to chemical cleaning the

installation. For cleaning new and old installations, use a suitable

cleaning agent, like Fernox Cleaner F3 (for old and heavily

contaminated installations use Cleaner F5). After this cleaning the

system should be rinsed with mains water.

Water treatment for filling the installation

Use the water with following parameters to fill the installation: pH

from 6,5 to 8,5 units, general hardness not more than

10 °n (~ 18°F).

For filling do not use demineralized water or distilled water. For

proper protection against scale and corrosion of the installation, use

a suitable inhibitor (passivator) e.g. Fernox Protector F1. In addition,

there can also be used a liquid heat carrier such as HP-5 or antifreeze

such as Fernox Alphi 11. In situations where water is very hard, the

use of the HP-5 liquid heat carrier effectively reduces the risk of

scaling of the heat exchanger.

Low-temperature circuits

In low-temperature zones it is recommended to treat the water by

using HP-5 liquid heat carrier or alternatively Fernox biocide AF10.

Filtering technology

In addition, modern filters with magnetic and cyclone effects are

recommended for the high quality of the current heating system.

The method and amount of use of the particular products for

cleaning the installation and for water treatment should be used

according to the instructions of the product given by the

manufacturer.

Cleaning the installation and water treatment should be made by

authorized installers or service personnel.