Removal and Installation Procedures

6- 36

TDS6000 Series Service Manual

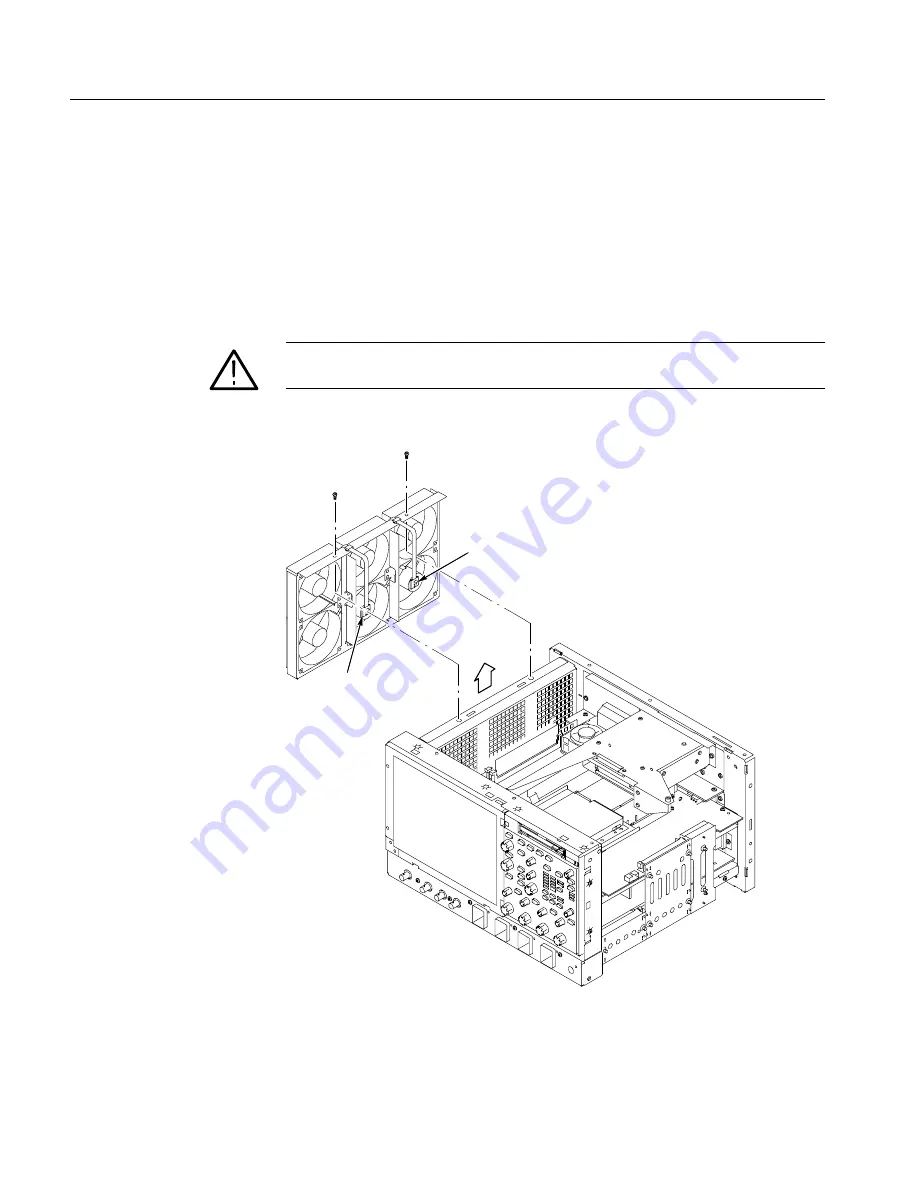

a.

Disconnect the fan from the processor/display board:

Disconnect the two

fan power cables J130 and J170 located on the processor board.

b.

Remove the two T-15 Torxdrive screws securing the fan assembly to the

top main chassis.

c.

Lift the fan assembly up and out from the chassis.

4.

Reinstallation:

Do in reverse steps a through c to reinstall the fan assembly.

CAUTION.

Take care when handling the fan assembly, the fan blades are brittle

and can be easily damaged.

Disconnect

from J130

Disconnect

from J170

Figure 6- 21: Fan assembly removal

Содержание TDS6404

Страница 4: ......

Страница 14: ...Table of Contents x TDS6000 Series Service Manual...

Страница 18: ...Service Safety Summary xiv TDS6000 Series Service Manual...

Страница 52: ...Operating Information 2 12 TDS6000 Series Service Manual...

Страница 56: ...Theory of Operation 3 4 TDS6000 Series Service Manual...

Страница 60: ...Performance Verification 4 4 TDS6000 Series Service Manual...

Страница 84: ...Performance Tests 4 28 TDS6000 Series Service Manual...

Страница 150: ...Adjustment Procedures 5 2 TDS6000 Series Service Manual...

Страница 156: ...Maintenance 6 6 TDS6000 Series Service Manual...

Страница 170: ...Removal and Installation Procedures 6 20 TDS6000 Series Service Manual...

Страница 228: ...Repackaging Instructions 6 78 TDS6000 Series Service Manual...

Страница 232: ...Options 7 4 TDS6000 Series Service Manual...

Страница 234: ...Electrical Parts List 8 2 TDS6000 Series Service Manual...

Страница 252: ...Mechanical Parts List 10 16 TDS6000 Series Service Manual...