27

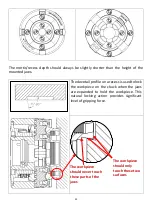

If the jaws are still running out of true, use a dial gauge

to measure the radial and axial runout of the jaws when

it is mounted on the chuck properly. The runout should

be measured between the ranges of the following:

1.

Radial runout

2.

Axial runout

Contact our customer services if the jaws are running

out of the maximum runout range above when they are

correctly mounted on the chucks.

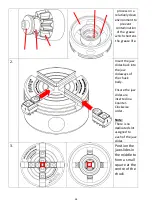

Jaw Slides closed to

center and No. 1 Slide

stays in center when jaws

are expanded again

The jaw slides may have over travelled and got

dislocated from the scroll ring. Ideally a complete

disassemble and assembly is required to correctly place

the jaw slides in place. By reassembling the chuck, it

allows for an opportunity to inspect all the chuck parts

for any defects (Especially around the scroll ring area).

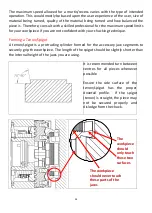

Chuck very stiff to

operate or jammed

Wood dusts will accumulate between parts over a

period of use. The wood dusts contaminate and

degrade the performance of the internal grease/

lubricants causing them to become very stiff.

When the grease/ lubricant becomes degraded, it must

be replaced with new lubricants to restore its

performance. Disassemble, clean all parts, apply new

grease/ lubricants on all necessary parts and

reassemble the chuck.

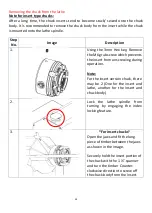

Jaw Slides when wound

to center do not meet

The jaw slides may have not engaged in the correct

sequence or it may not be engaged with the correct

teeth of the scroll ring.

First, ensure the jaw slides are inserted in a sequential

order in the counterclockwise direction.

Secondly, disassemble the chuck and physically place

the jaw slides in the center and engage the scroll ring.

When chuck is being

removed from spindle the

body unwinds from insert

Either lock insert in body using grub screw and fiber

washer provided or use insert spanner on the insert to

wind chuck off lathe.

Содержание nova PRO-TEK SUPERNOVA2

Страница 11: ...11 PRO TEK SUPERNOVA2 Chuck Parts View ...