1.1 General Design and Operation

The Dynapump LE Series is a combined centrifugal

pump and squirrel cage induction electric motor built

together into a single hermetically sealed unit. The

pump impeller is of the closed type, and is mounted

on one end of the rotor shaft, which extends from the

motor section into the pump casing. The rotor is sub-

merged in the fluid being pumped and is, therefore,

“canned” to isolate the motor rotor from contact with

the fluid. The stator winding is also “canned” to iso-

late it from the fluid being pumped. Bearings are

submerged in system fluid and are therefore, lubri-

cated by the process fluid.

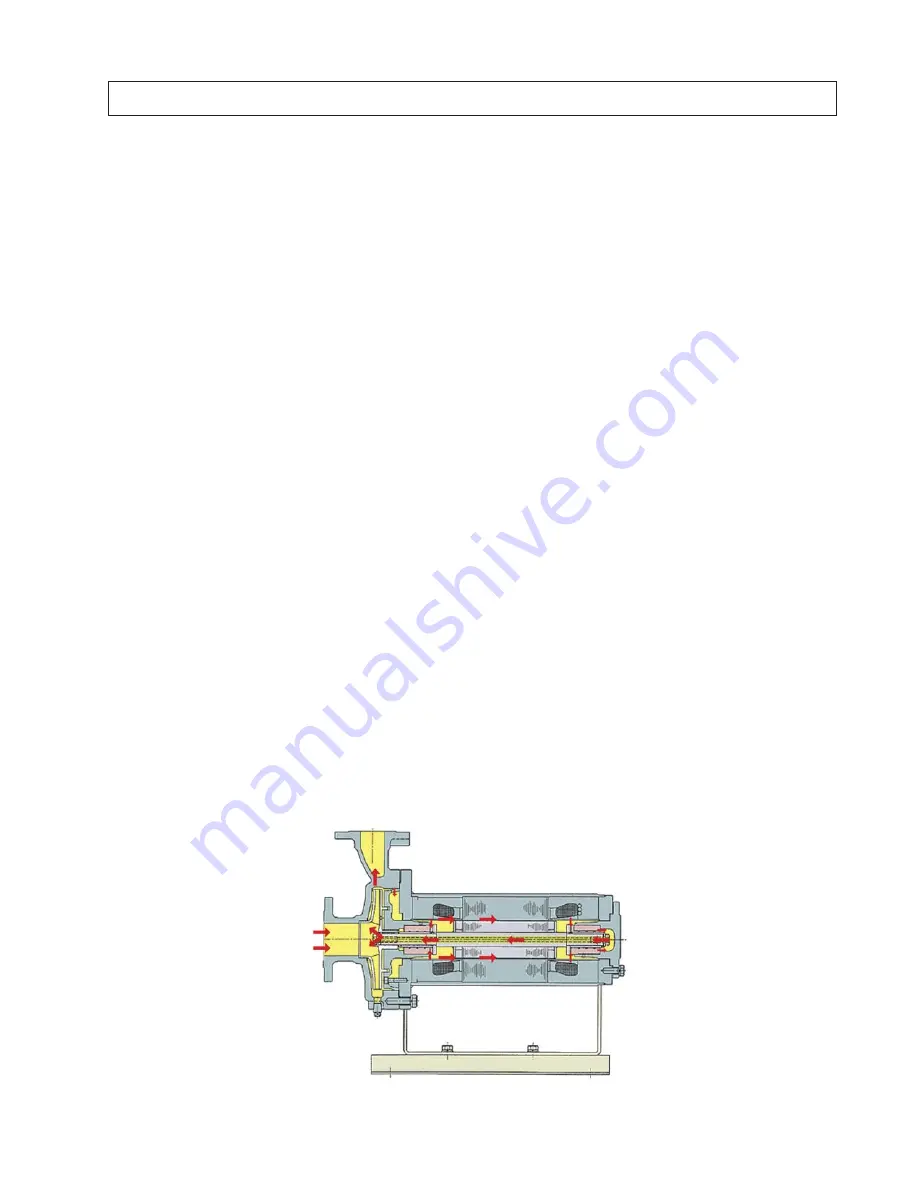

The Dynapump LE has only one moving part, a com-

bined rotor-impeller assembly that is driven by the

induced magnetic field of an induction motor. A por-

tion of the pumped fluid is allowed to re-circulate

through the rotor cavity to cool the motor and lubri-

cate the bearings. The stator windings are protected

from contact with the re-circulating fluid by a corro-

sion resistant, non-magnetic, alloy liner, which com-

pletely seals or “cans” the stator winding. The re-

circulating fluid is channeled into the motor section

by holes drilled in the front bearing housing. A por-

tion of the pumpage flows across the front bearing

and returns to the rear of the impeller. The remain-

der passes over the rotor, across the rear bearing,

and returns to suction through a hollow shaft. See

Figure 1-1.

The Dynapump LE offers true positive secondary

containment as a standard design feature. In the

event of a failure of the primary containment can, the

stator assembly in conjunction with the leak proof

terminal post assembly provides the secondary con-

SECTION 1. General Information

Page 1

Figure 1-1. Dynapump LE Series Standard Circulation

tainment. This design prevents any release of the

process fluid out to the atmosphere.

A standard feature of the Dynapump LE is the pat-

ented Teikoku Rotary Guardian (TRG). The TRG is

an electrical meter that continuously monitors the

condition of the bearings. For more information on

the TRG refer to 2-3.4 Bearing Wear Monitor, Page 7.

The Dynapump LE sealless pump is a precision-

built unit that, with proper care, will give years of

trouble-free, leakproof service. The entire unit is

mounted on a fabricated steel base cradle. Opera-

tion is unaffected by the mounting or operating posi-

tion, eliminating the need for any costly alignment

procedures. This manual, containing basic instruc-

tions for installation, operation and maintenance of

the Dynapump LE Series, is designed to assist you

in obtaining this service.

It is important that the persons responsible for the

installation, operation, and maintenance of the pump,

read and understand the manual thoroughly.

Trouble-free Dynapump LE performance begins with

proper pump selection and application. If the se-

lected pump does not have the required performance

characteristics, or if the materials of construction are

not properly specified for the fluid being handled,

unsatisfactory operation may result. No amount of

maintenance can compensate for this.

If you are in doubt about proper Dynapump LE selec-

tion or application, write or call your Dynapump LE

engineering representative or the factory for assis-

tance. Additional copies of this manual are available

from the Dynapump LE field representative, the fac-

tory or on our website: www.dynapump.com.

Содержание DynaPump LE Series

Страница 2: ...This page intentionally blank...

Страница 6: ...This page intentionally blank...

Страница 10: ...This page intentionally blank...

Страница 16: ...This page intentionally blank...

Страница 21: ...Figure 4 2 g Gap Figure 4 1 Bearing Wear Page 13...

Страница 23: ...APPENDIX...

Страница 27: ...A 4...

Страница 28: ...A 5...

Страница 29: ...A 6...

Страница 30: ...A 7...