64

Instruction and maintenance manual

ENGLISH

ing force applied to the part is directly related to

the number of available extensions.

ATTENTION! The holes on the poles are

provided to simplify the positioning of accesso-

ries like polar extensions (see page 59, section 5).

It is useful to remember that these accessories

act as conductors and do not need therefore to

be excessively clamped. To accelerate the posi-

tioning of these accessories, holes with a limited

thread are provided. These holes are designed

to be used for the operations described above

only. A tight and repeated clamping may wear the

threads of the holes on the poles.

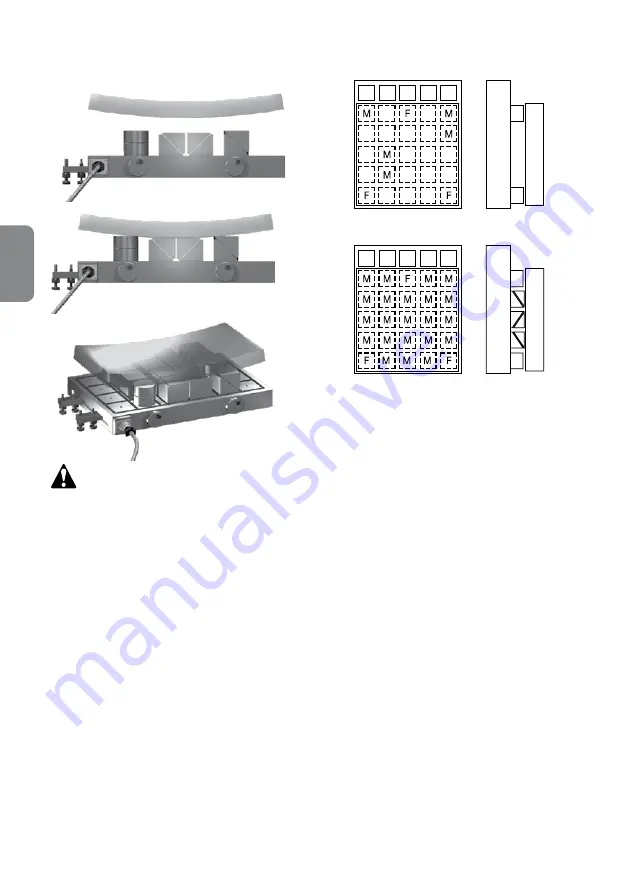

INCORRECT

POSITION

CORRECT

POSITION

Use the polar extensions (for milling operations) to

verify that all the surface of the part to machine is

covered with the polar extensions.

The clamping force is directly proportional to the

surface in contact with the part to clamp (and thus

to the number of polar extensions).

The greater the number and the higher the clamp-

ing force

Verify that the polar extensions are correctly po-

sitioned, checking also the magnetic balancing

(number of poles with SOUTH polarity = NORTH

polarity).

In other words, if it is not possible to use the whole

surface of the part for magnetic clamping, it is pos-

sible to use polar extensions to verify that the exten-

sions present meet the following conditions:

a) The number of extensions with North (N) polarity

must be equivalent to the number of extensions

with South (S) polarity. It is generally sufficient

to arrange the extensions so that they face one

another, as this configuration ensures a correct

alternation between north and south.

b) The polar extensions that are in contact with the

part should be placed, when possible, along the

whole length of the part. This ensures that the

clamping force is able to effectively offset the cut-

ting force.