8-2

TROUBLESHOOTING GUIDE

Models C709 & C717

Troubleshooting Guide

8

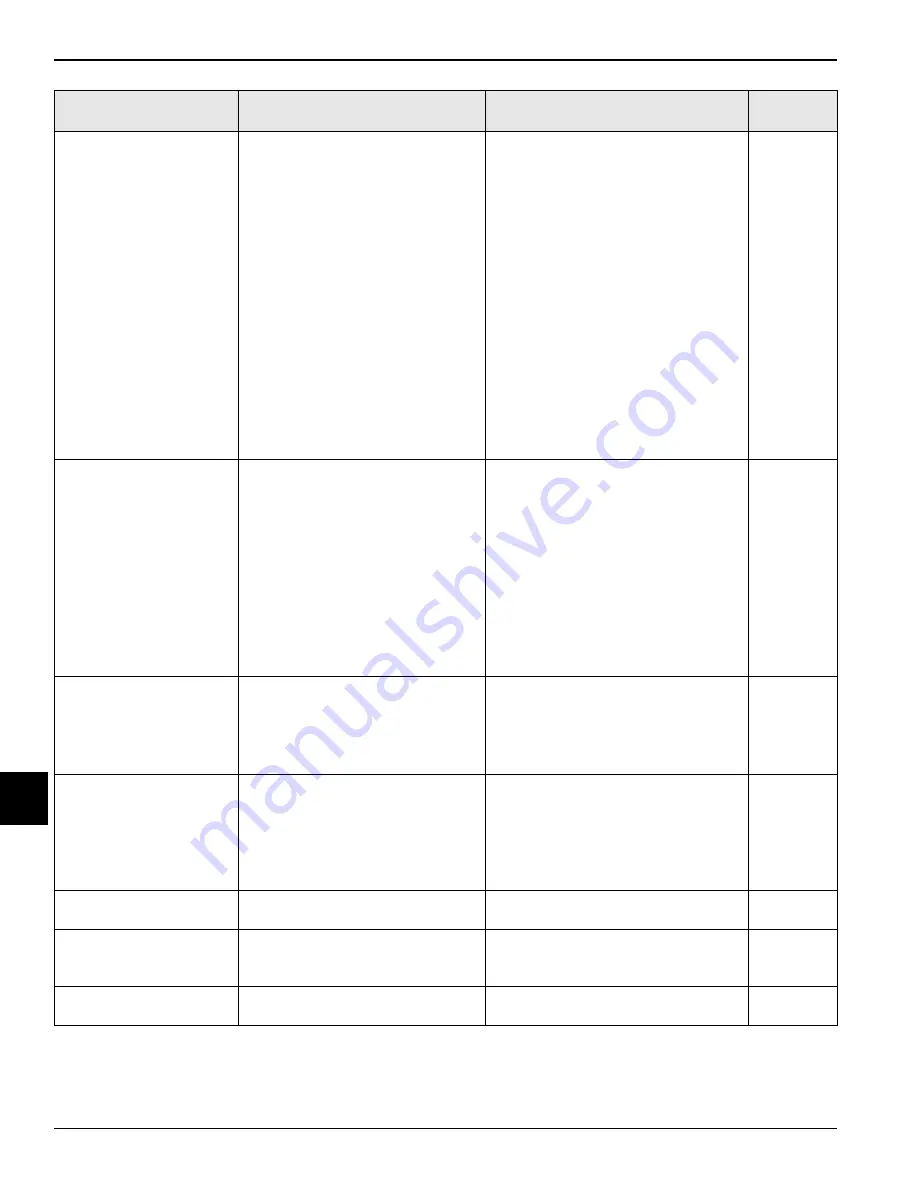

3. No product is being

dispensed.

a. Low on mix.The MIX OUT light is

on.

a. Add mix to the mix hopper. Return to

Auto mode.

b. The power switch is in the OFF

position.

c. Place the power switch to ON and

select Auto mode.

c. The circuit breaker is off or the fuse

is blown.

d. Turn the breaker on or replace the

fuse.

- - -

d. Beater motor is out on reset,

BEATER OVERLOAD message

displayed.

e. Turn the machine off. Press the

RESET button. Restart the machine

in Auto mode.

- - -

e. Machine is not in Auto mode.

f. Select Auto mode and allow machine

to cycle off before drawing product.

f. Feed tube not properly installed.

g. Make sure the feed tube is properly

installed.

g. Freeze-up in mix inlet hole.

h. Call a Taylor service technician.

- - -

h. The beater is rotating

counterclockwise when observed

from the operator end.

i. Contact a Taylor service technician to

correct rotation.

4. The product is too soft.

a. Draw rate is set too fast.

a. Adjust draw rate of 5 oz. to 7 1/2 oz.

(142 g to 213 g) of product by weight

in 10 seconds.

b. Not enough airspace around

machine. (Air-cooled machines).

b. Allow for adequate airflow across the

condenser.

c. Worn scraper blades.

c. Replace regularly.

d. Dirty condenser (A/C).

d. Clean monthly.

e. Mix is out of date.

e. Use only

fresh

mix.

- - -

f. Loss of water (W/C).

f. Locate cause of water loss and

correct.

g. Viscosity needs adjustment.

g. Contact a Taylor service technician.

- - -

5. The product is too thick.

a. Freezing cylinder not primed

correctly.

a. Drain the freezing cylinder and

reprime the machine.

b. The viscosity control is set too

cold.

b. Call a Taylor service technician.

- - -

c. Freeze-up in mix inlet hole.

c. Call a Taylor service technician.

- - -

6. The mix in the hopper is

too warm.

a. Hopper cover is not in position.

a. Clean and sanitize the hopper cover

and place in position.

b. The agitator is not installed.

b. Clean and sanitize the agitator and

install.

c. The hopper temperature is out of

adjustment.

c. Call a Taylor service technician.

- - -

7. The mix in the hopper is

too cold.

a. The hopper temperature is out of

adjustment.

a. Call a Taylor service technician.

- - -

8. Mix Low and Mix Out

probes are not

functioning.

a. Milkstone buildup in the hopper.

a. Clean hopper(s) thoroughly.

9. Product is collecting on

top of the freezer door.

a. The top O-ring on the draw valve is

improperly lubricated or worn.

a. Lubricate properly or replace the

O-ring.

Problem

Probable Cause

Remedy

Page

Ref.

Содержание C709

Страница 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Страница 22: ...4 10 OPERATOR PARTS IDENTIFICATION Models C709 C717 Operator Parts Identification 4 Notes...

Страница 58: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Страница 60: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Страница 64: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Страница 68: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...