USER INTERFACE

5-15

Models C709 & C717

User Interface

5

Heat Cycle Summary

The HEAT CYCLE SUMMARY screen displays the hours

since the last Heat cycle, the hours since the product

temperature was above 150°F (65.6°C), and the number

of Heat cycles completed since the last brush-clean date.

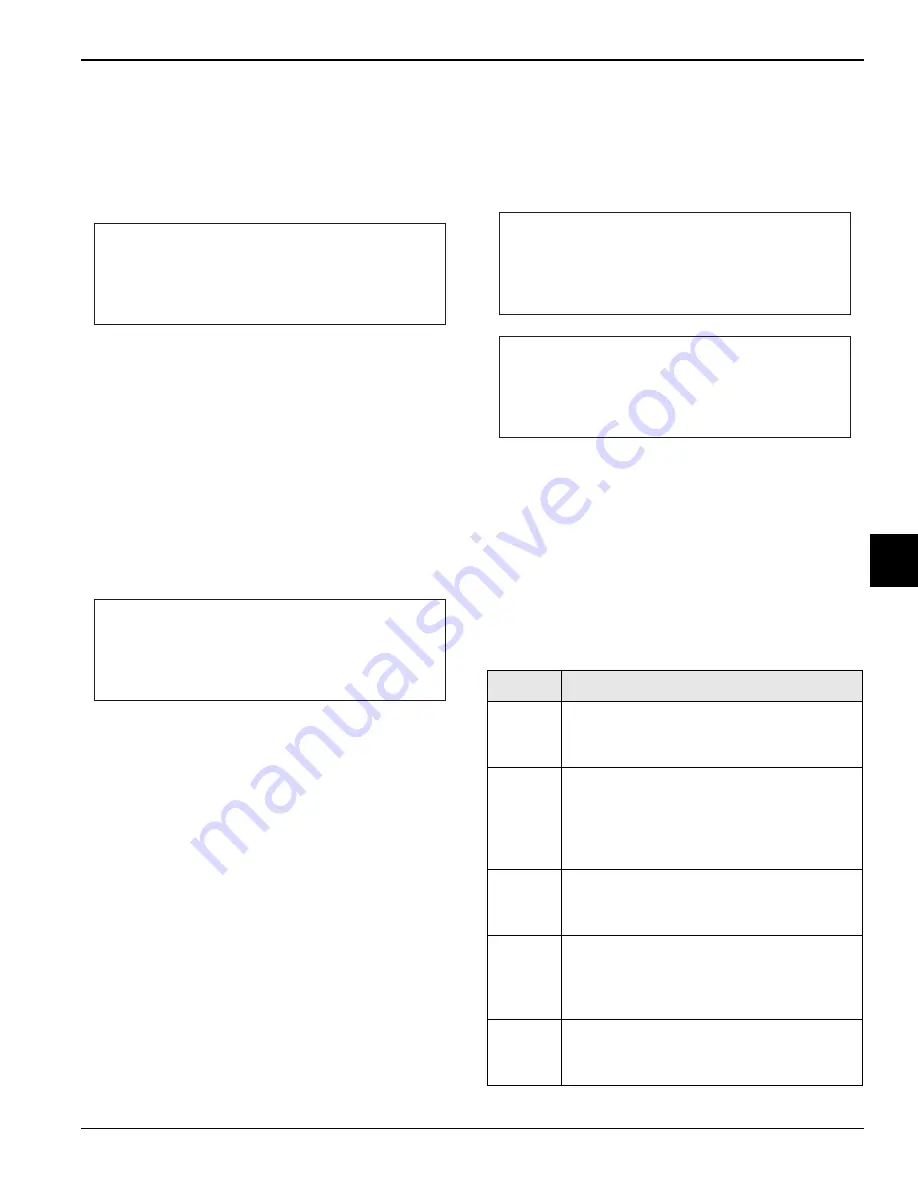

Heat Cycle Data

The HEAT CYCLE DATA screen contains a record of up

to 366 Heat Treatment cycles. The most recent Heat

cycle data will be shown first.

Each Heat cycle record has three screens. The first

screen displays the month and day of the Heat cycle, the

start time and end time, and the fault description. The

bottom line displays the record number and indicates if a

power failure occurred during the Heat cycle (POWER

FAILURE IN HC).

Press the Up arrow key to advance forward through the

data pages. Press the Down arrow key to reverse the

page direction.

Hopper and barrel temperature records for each side of

the freezer are displayed in the second and third screens.

The second screen shows the left side (L) of the freezer.

The third screen shows the right side (R) of the freezer.

The top line of these screens shows the hopper (H) and

barrel (B) temperatures recorded at the end of the Heat

Treatment cycle and indicates the side (L or R) of the

freezer.

The remaining lines indicate the following.

HEAT =

Total time for the hopper (h) and barrel (b) to

reach 150.9°F (66.1°C).

OVER =

Total time the hopper (h) and barrel (b)

temperature was above 150°F (65.6°C).

COOL =

Total time the hopper (h) and barrel (b)

temperature was above 41°F (5°C) during the cool

phase.

PEAK =

Highest temperature reading for the hopper (h)

and barrel (b) during the Heat Treatment cycle.

The heat time indicates the amount of time taken in each

zone to reach 150.9°F (66.1°C). Each zone must remain

above 150°F (65.6°C) for a minimum of 35 minutes.

Press the Up arrow key to advance to the next page or

the Down arrow key to view the previous page. A Heat

Cycle Failure message will display on the first screen if a

failure occurred.

Note:

Listed below are variable failure code messages

that could appear on line 2.

Table 5-2

HEAT CYCLE SUMMARY

0

C

H

E

C

N

I

S

S

R

H

0

0

5

1

E

C

N

I

S

S

R

H

0

C

B

E

C

N

I

S

C

H

HEAT TREAT CYCLE

01/01

02:00

05:14

NO FAULT FOUND

1

Code

Failure Message

HT

HEAT TIME FAILURE

Mix temperature did not rise above 151°F

(66.1°C) in less than 90 minutes.

CL

COOL MODE FAILURE

Mix temperature in the hopper and freezing

cylinder did not fall below 41°F (5°C) in less

than 90 minutes for UVC3 machines or 120

minutes for UVC4 machines.

TT

TOTAL TIME FAILURE

The Heat Treatment cycle must be completed

in no more than 4 hours.

ML

MIX LOW FAILURE

The heat phase or cool phase time was

exceeded and a Mix Low condition was

present.

MO

MIX OUT FAILURE

A Mix Out condition was detected at the start of

or during the Heat cycle.

H: 40.9

B:26.3

L

HEAT OVER COOL

PEAK

1:12

0:49 h 1:19

161.0

0:46

1:11 b 0:15

169.7

H: 38.0

B:23.7

R

HEAT OVER COOL

PEAK

1:09

0:52

h 1:11

161.2

0:66

1:00

b 0:11

169.9

Содержание C709

Страница 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Страница 22: ...4 10 OPERATOR PARTS IDENTIFICATION Models C709 C717 Operator Parts Identification 4 Notes...

Страница 58: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Страница 60: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Страница 64: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Страница 68: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...