6-6

OPERATING PROCEDURES

Models C709 & C717

Operating Procedures

6

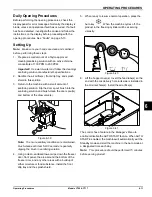

7.

Insert the draw valves from the bottom until the slot in

each draw valve comes into view.

Figure 6-23

8.

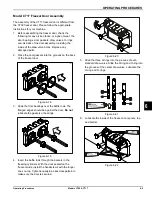

Position each draw handle with the adjustment screw

facing down. Slide the fork of each draw handle into

the slot of each draw valve, starting from the right.

9.

Slide the pivot pin through the draw handles as the

handles are inserted into the draw valves.

Figure 6-24

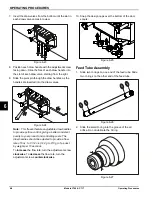

Note:

This freezer features adjustable draw handles

to provide portion control, giving a better consistent

quality to your product and controlling costs. The

draw handles should be adjusted to provide a flow

rate of 5

oz.

to 7-1/2 oz. (142 g to 213 g) of product

by weight per 10 seconds.

To

increase

the flow rate, turn the adjustment screw

clockwise

. To

decrease

the flow rate, turn the

adjustment screw

counterclockwise

.

10. Snap the design caps over the bottom of the door

spouts.

Figure 6-25

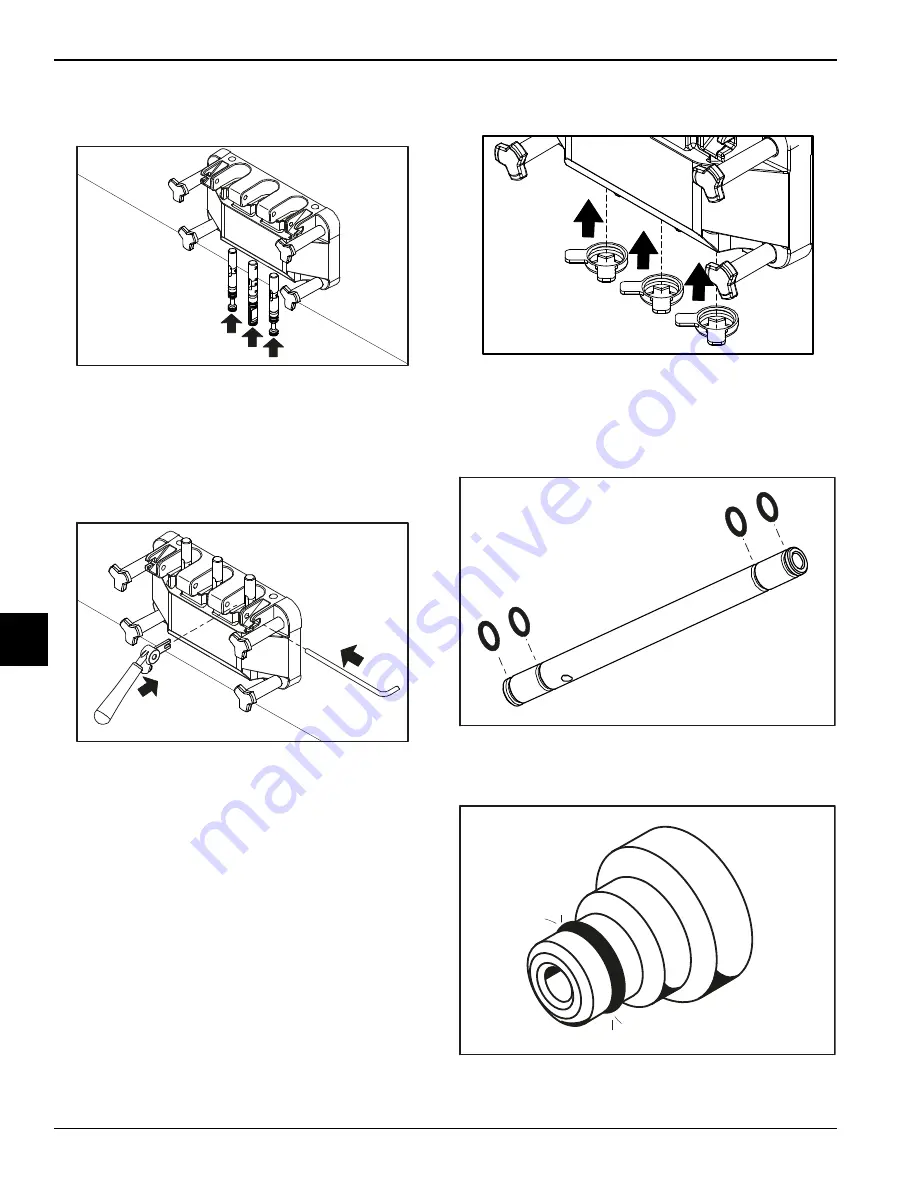

Feed Tube Assembly

1. Slide two O-rings on one end of the feed tube. Slide

two O-rings on the other end of the feed tube.

Figure 6-26

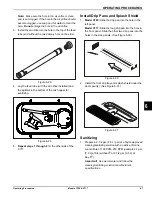

2. Slide the small O-ring into the groove of the air

orifice. Do not lubricate the O-ring.

Figure 6-27

101534

101535

101544

12317

12077

Содержание C709

Страница 8: ...1 4 TO THE INSTALLER Models C709 C717 To the Installer 1 Notes...

Страница 22: ...4 10 OPERATOR PARTS IDENTIFICATION Models C709 C717 Operator Parts Identification 4 Notes...

Страница 58: ...8 4 TROUBLESHOOTING GUIDE Models C709 C717 Troubleshooting Guide 8 Notes...

Страница 60: ...9 2 PARTS REPLACEMENT SCHEDULE Models C709 C717 Parts Replacement Schedule 9 Notes...

Страница 64: ...10 4 LIMITED WARRANTY ON EQUIPMENT Models C709 C717 Limited Warranty on Equipment 10 Notes...

Страница 68: ...11 4 LIMITED WARRANTY ON PARTS Models C709 C717 Limited Warranty on Parts 11 Notes...