After Sales Support

TEL: 1300 922 271 EMAIL: [email protected]

14

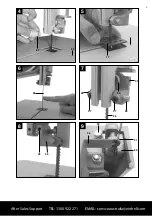

10.1. Longitudinal cuts (Fig.20)

Longitudinal cutting is when you use the saw to cut along the

grain of the wood.

•

Place the parallel stop (Fig.20/Item 24) to the left of the

blade (Fig.2/Item 26), as far as possible, for the width

required.

•

Lower the blade guide (Fig.20/Item 11) down to the

workpiece (see 8.5).

•

Switch on the saw.

•

Press the edge of the workpiece with your right hand to

hold it securely against the parallel stop (Fig.20/Item 24)

and flat on the table (Fig.20/Item 15).

•

Guide the workpiece along the parallel stop

(Fig.20/Item 24) and through the blade (Fig.2/Item 26)

at a uniform speed.

•

Important:

Long workpieces must be secured against

falling off at the end of the cut (e.g. with a roller stand etc.)

10.2. Angular cuts (Fig.19)

To enable you to perform angular cuts parallel to the blade

(Fig.19/Item 26) , the table (Fig.19/Item 15) can be tilted

forwards between 0° - 45°.

•

Undo the fixing handles (Fig.2/Item 18).

•

Tilt the saw table (Fig.19/Item 15) forwards until the

required angle value is set on the dial scale (Fig.2/Item 16).

•

Re-tighten the fixing handles (Fig.2/Item 18).

•

Important:

When the table (Fig.19/Item 15) is tilted, place

the parallel stop (Fig.19/ Item 24) to the right of the blade

(Fig.19/Item 26) looking in the direction in which you are

working, on the side pointing downwards (provided the

workpiece is wide enough in order to stop the workpiece

from slipping off).

•

Carry out the cut as described in 10.1.

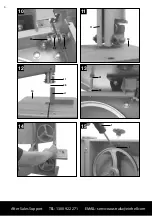

10.3. Freehanded cuts (Figure 21)

One of the most outstanding features of a bandsaw is the ease

with which it allows you to make curved cuts and radius.

•

Lower the blade guide (Fig.21/Item 11) to the workpiece

(see 8.5).

•

Switch on the saw.

•

Hold the workpiece securely on the table (Fig.21/Item 15)

and guide slowly through the blade (Fig.2/Item 26).

•

Freehanded cuts should be made at low feed speed so

that you can guide the blade (Fig.2/Item 26) along the

required line.

•

It often pays to first cut off surplus curves and corners up

to about 6 mm from the cutting line.

•

In the case of curves which are too tight for the blade to

cut correctly, it can help to make a series of close-lying

cuts at right angles to the curved line. When you saw the

radius the material will simply drop off.

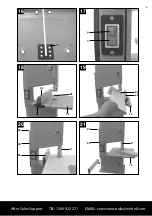

11. Transport

To transport the bandsaw, hold the supporting foot

(Fig.1/Item 5) with one hand and the frame (Fig.2/Item 25)

with the other hand.

Important!

Never use guards to lift or

transport the equipment.

12. Maintenance

•

Caution!

Pull out the power plug first.

•

Remove dust and dirt regularly from the bandsaw.

Cleaning is best carried out with a fine brush or a cloth.

•

Do not use caustic cleaning agents for cleaning plastic.

13. Ordering spare parts

Contact our After Sales Support on 1300 922 271 and quote

the following data when ordering spare parts:

•

Type of machine

•

Article number of the machine

•

Identification number of the machine

•

Spare part number of the part required

14. Disposal and recycling

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material and

can therefore be reused or can be returned to the raw

material system.

The unit and its accessories are made of various types of

material, such as metal and plastic. Defective components

must be disposed of as special waste. Ask your local council.