After Sales Support

TEL: 1300 922 271 EMAIL: [email protected]

13

8.7. Blade selection

The blade supplied with the bandsaw is designed for all-

purpose use. When you select a blade you should have regard

to the following criteria:

•

Use a narrow blade to cut tighter radius than you can with

a wider blade.

•

Wide blades are used to saw straight cuts. This is

particularly important in cutting wood because the blade

has a tendency to follow the grain of the wood and there

by deviate easily from the cutting line.

•

Finely toothed blades provide smoother cuts but are

slower than coarse blades.

Important: Never use warped or lacerated blades!

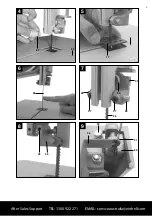

8.8. Changing the blade (Fig.14)

•

Move the blade guide (Fig. 1/Item 11) into a position

approximately half way between the saw table

(Fig.1/Item 15) and the machine housing (Fig.2/Item 25).

•

Undo the fasteners (Fig.1/Item 13) and open the side

cover (Fig. 1/Item 12).

•

Remove the web panel (Fig.3/Item 4).

•

Turn the tightening screw (Fig.1/Item 9) anti-clockwise to

remove the tension from the blade (Fig.2/Item 26).

•

Remove the blade (Fig.2/Item 26) from the blade pulleys

(Fig.1/Item 7 & 8) and take out through the slot in the table

(Fig.1/Item 15).

•

Fit the new blade (Fig.2/Item 26), aligned centrally on the

blade pulleys (Fig.1/Item 7 & 8).

•

The teeth of the blade (Fig.2/Item 26) must point

downwards in the direction of the table.

•

Tension the blade (Fig.2/Item 26) (see 8.2)

•

Close the side cover (Fig.1/Item 12) again.

•

Mount the web panel (Fig.3/Item 4) again.

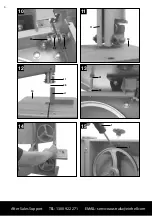

8.9. Changing the rubber tires on the blade pulleys

After a certain time the rubber tires (Fig.15/Item 3) on the

blade pulleys (Fig.1/Item 7 & 8) will get worn by the sharp teeth

of the blades and must be replaced.

•

Open the side cover (Fig.1/Item 12).

•

Remove the blade (Fig.2/Item 26) (see 8.7).

•

Lift the edge of the tire (Fig.15/Item 3) with a small

screwdriver (Fig.15/Item f) and remove from the upper

blade pulley (Fig.1/Item 8).

•

Repeat for the lower blade pulley (Fig.1/Item 7).

•

Fit the new tire (Fig.15/Item 3), replace the blade

(Fig.2/Item 26) and close the side cover (Fig.1/Item12).

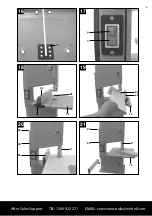

8.10. Changing the table insert (Fig.16)

To prevent increased likelihood of injury the table insert

(Fig.16/Item 17) should be changed whenever it is worn

or damaged.

•

Detach the table (Fig.1/Item 15) (see 8.1).

•

Lift out the worn table insert (Fig.16/Item 17).

•

Fit the replacement table insert by following the above

in reverse.

8.11. Extractor sockets

The bandsaw is equipped with extractor sockets (Fig.1/Item 6)

for extracting sawdust and chips.

9. Control elements

9.1. On/Off switch (Fig.17)

•

To turn the machine on, press the green button “l” (g).

•

To turn the machine off again, press the red button “0“ (h).

•

Your bandsaw has a switch with under voltage release.

After a power failure you must re-activate the switch.

9.2. Parallel stop (Fig.18)

•

Push the clip (21) on the parallel stop (24) upwards.

•

Move the parallel stop (24) along the table (15), from

either the right or left of the blade (26), and position

as required.

•

Push the clip (21) down to fix the parallel stop (24). If the

clip (21) does not give enough hold, turn it clockwise

several times until the parallel stop is securely fixed.

•

You must always ensure that the parallel stop (24) is

positioned parallel to the blade (26).

10. Operation

Caution!

After every new adjustment we recommend to make

a trial cut in order to check the new settings.

•

For all cutting operations it is important to position the blade

guide (Fig.1/Item 11) as close as possible to the workpiece

(see 8.5).

•

Always guide the workpiece with both hands, holding

it flat on the table (Fig.1/Item 15) in order to prevent the

blade (Fig.2/Item 26) from jamming.

•

Feed the workpiece at a uniform speed that enables the

blade to cut through the material without difficulty and

without blocking.

•

Always use the parallel stop (Fig.2/Item 26) on all cuts for

which they are intended.

•

Always aim at making a complete cut in one pass rather

than in a stop-and-go operation requiring the workpiece

to be withdrawn. If you have to withdraw the workpiece,

switch off the bandsaw first and wait for the blade (Fig.2/

Item 26) to stop before freeing the workpiece.

•

The workpiece must always be guided by the longer side

during cutting.

Important!

When handling narrower workpieces, it is

essential to use a push stick.The push stick (Fig.20/Item 28)

must always be kept close at hand at the hook (Fig.20/Item 29)

provided for that purpose on the side of the saw.