4-157

4

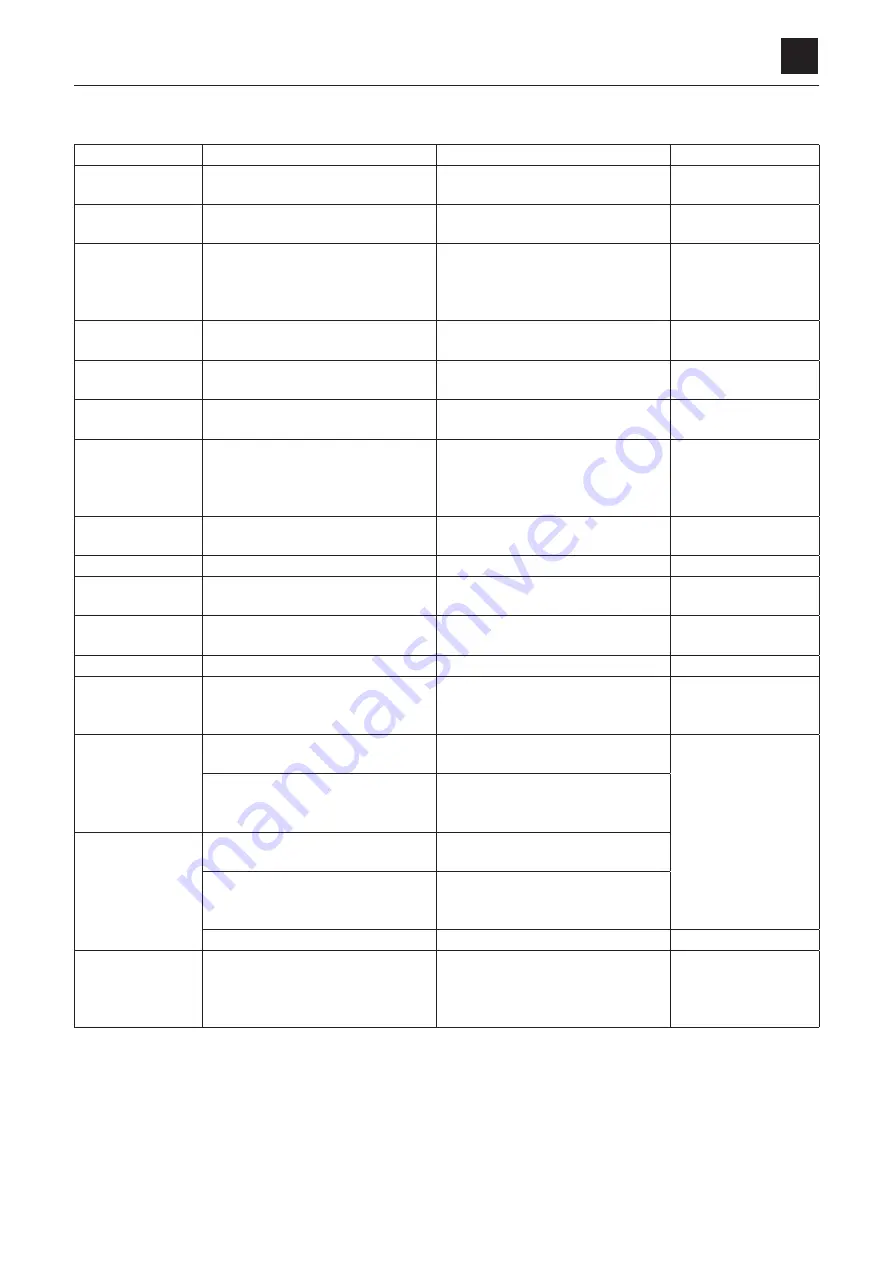

TRAVEL MOTOR

DISASSEMBLY AND ASSEMBLY

Inspection and adjustment

Use limit for parts

Part

Area checked

Judgment criteria

Treatment

Floating seal

Sliding surface

Abnormal scratches, wear or scorch-

ing on the surface

Replace

Angular bearing

Rolling surface

Abnormal scratches, wear or flaking

on the ball or race.

Replace

Planetary gear

Gear tooth surface

Abnormal scratches, wear or flaking

of the tooth surface (if pitting covers

10% or more of the area engaging

with the tooth surface).

Replace

Inner race

Rolling surface

Abnormal scratches, wear or flaking

on the rolling surface

Replace

Needle

Needle surface

Abnormal scratches, wear or flaking

on the surface

Replace

Thrust washer

Sliding surface

Abnormal scratches, wear or scorch-

ing on the surface

Replace

Housing, sun gear,

drive gear

Gear tooth surface

Abnormal scratches, wear or flaking

of the tooth surfaces (if pitting cov-

ers 10% or more of the area engag-

ing with the tooth surface).

Replace

Thrust plate

Sliding surfaces

Abnormal scratches, wear or scorch-

ing on the surface

Replace

O-ring

––

––

Replace

Shaft

Oil seal surface

Abnormal scratches, wear or scorch-

ing on the surface

Replace

Ball bearing

Sliding surfaces

Abnormal scratches or flaking on the

ball or race.

Replace

Oil seal

––

––

Replace

Swash plate

Sliding surface with the piston as-

sembly

Abnormal scratches (0.02 mm or

more), wear or scorching on the sur-

faces

Replace

Cylinder block

Cylinder block-to-piston assembly

clearance

0.04 mm or more

Repair by lapping

(#1000) or replace

both cylinder block

and piston assembly.

Sliding surface with the valve plate

Abnormal scratches (0.02 mm or

more), wear or scorching on the sur-

faces

Piston assembly

Piston assembly-to-cylinder block

clearance

0.04 mm or more

Sliding surface with the swash plate Abnormal scratches (0.02 mm or

more), wear or scorching on the sur-

faces

Play of piston shoe

0.04 mm or more

Replace

Valve plate

Sliding surface with the cylinder

block

Abnormal scratches (0.02 mm or

more), wear or scorching on the sur-

faces

Repair by lapping

(#1000) or replace

both cylinder block

and piston assembly.

Содержание TB 250

Страница 1: ......

Страница 3: ...1 1 SAFETY 1 Safety alert symbol 1 2 Safety precautions 1 3 Cautions when working 1 9...

Страница 36: ...2 24 2 TIGHTENING TORQUE SERVICE DATA...

Страница 37: ...2 25 2 SERVICE DATA HYDRAULIC CIRCUIT DIAGRAM HYDRAULIC CIRCUIT DIAGRAM Equipped with options 1 2...

Страница 38: ...2 26 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with options 2 2...

Страница 39: ...2 27 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with angle blade and blade oat 1 2...

Страница 40: ...2 28 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with angle blade and blade oat 2 2...

Страница 41: ...2 29 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow option 1 2...

Страница 42: ...2 30 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow option 2 2...

Страница 43: ...2 31 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow angle blade blade oat option 1 2...

Страница 44: ...2 32 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow angle blade blade oat option 2 2...

Страница 46: ...2 34 2 ELECTRIC CIRCUIT DIAGRAM SERVICE DATA First auxiliary hydraulic piping with proportional control...

Страница 49: ......

Страница 59: ...2 46 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 60: ...2 47 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 61: ...2 48 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 62: ...2 49 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 63: ...2 50 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 64: ...2 51 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 65: ...2 52 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 66: ...2 53 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 67: ...2 54 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 68: ...2 55 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 69: ...2 56 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 70: ...2 57 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 71: ...2 58 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 72: ...2 59 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 73: ...2 60 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA NAME STANDARD NO...

Страница 74: ...2 61 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 75: ...2 62 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 76: ...2 63 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 77: ...2 64 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 78: ...2 65 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 79: ...2 66 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 80: ...2 67 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 81: ...2 68 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 92: ...3 11 3 CONTROL VALVE FUNCTION...

Страница 108: ...4 3 4 SERVICE STANDARDS DISASSEMBLY AND ASSEMBLY Clearance for pin and bushing...

Страница 130: ...4 25 4 UPPER FRAME DISASSEMBLY AND ASSEMBLY 15 Side frame R 16 Side frame L 17 Tool box 18 Cover 19 Bracket 20 Cover 2 2...

Страница 165: ...4 60 4 HYDRAULIC PUMP DISASSEMBLY AND ASSEMBLY f Remove the plug g Remove the spring and the ball...

Страница 267: ...4 162 4 SLEW MOTOR DISASSEMBLY AND ASSEMBLY Special tools Oil seal press tting jig A Collar installation jig B...

Страница 352: ...ENGINE 6 Machine model Mounted engine TB250 4TNV88...