4-83

4

CONTROL VALVE

DISASSEMBLY AND ASSEMBLY

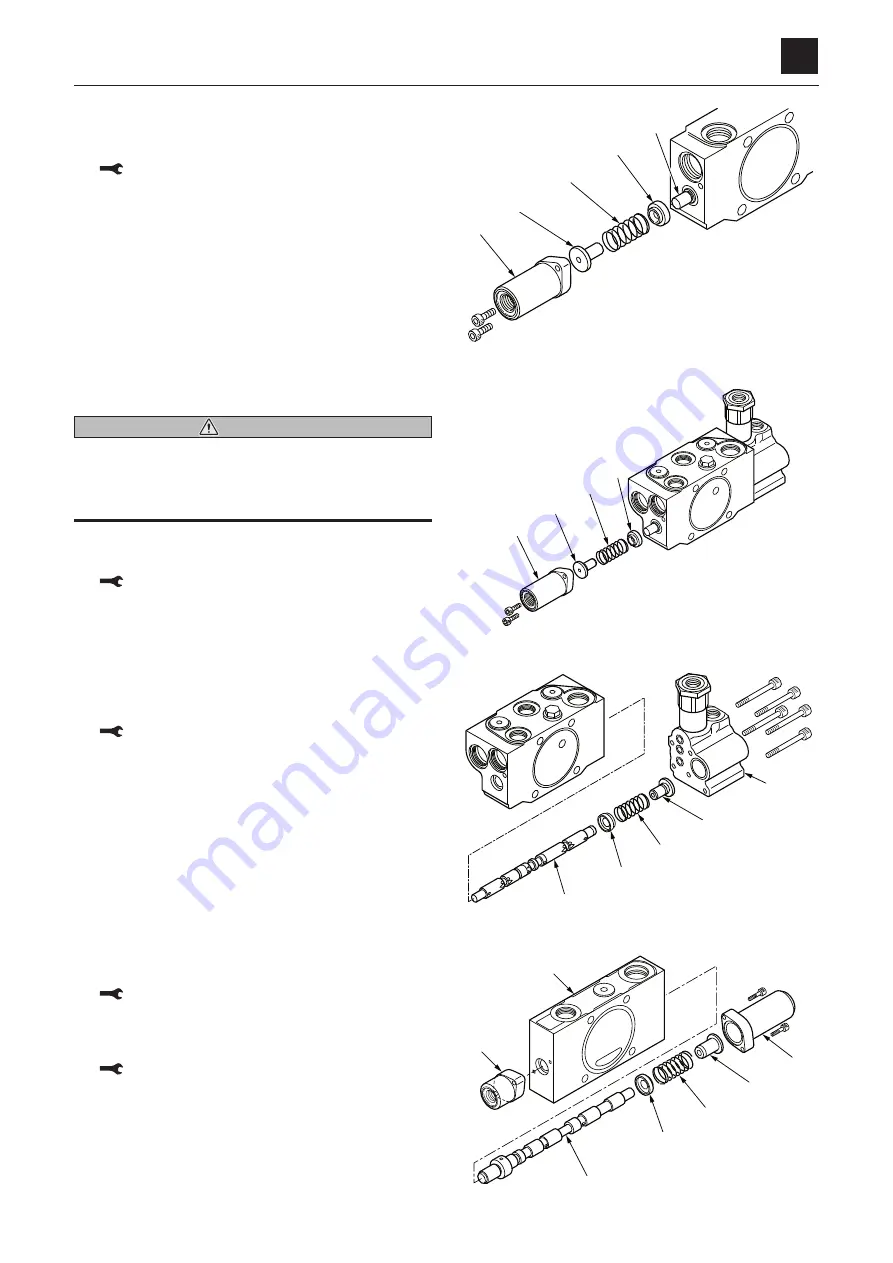

Pilot operated section

1. Remove the cap screws and cover (1), and then re-

move the O-ring from the cover (1).

Cap screw: 8.8 to 10.8 N·m

2. Remove the spring holder (2), spring (3) and spring

holder (4).

3. Remove the spool (5) from the housing.

• Make sure to insert the spool in the correct direc-

tion.

Boom section

WARNING

If the anti-drift valve is disassembled with the control

valve still installed, parts may be ejected due to the

internal pressure. Remove it after relieving the internal

pressure by gradually loosening the cap screw.

1. Remove the cap screws and cover (1), and then re-

move the O-ring from the cover.

Cap screw: 8.8 to 10.8 N·m

2. Remove the spring holder (2), spring (3) and spring

holder (4).

3. Take out the cap screws and housing (5), and then re-

move the O-ring from the housing.

• Do not further disassemble the anti-drift valve.

Cap screw: 8.8 to 10.8 N·m

4. Remove the spring holder (2), spring (3) and spring

holder (4).

5. Remove the spool assembly (6) from the housing.

• Make sure to insert the spool in the correct direc-

tion.

Switch valve

1. Remove the cap screws and cover (1), and then re-

move the O-ring from the cover (1).

Cap screw: 8.8 to 10.8 N·m

2. Remove the cap screws and cover (3), and then re-

move the O-ring from the cover (3).

Cap screw: 8.8 to 10.8 N·m

3. Remove the spring holder (4), spring (5) and spring

holder (6).

4. Remove the spool (7) from the housing.

• Be sure to insert the spool in the correct direction.

��������

�

�

�

�

�

��������

�

�

�

�

��������

�

�

�

�

�

��������

�

�

�

�

�

�

�

Содержание TB 250

Страница 1: ......

Страница 3: ...1 1 SAFETY 1 Safety alert symbol 1 2 Safety precautions 1 3 Cautions when working 1 9...

Страница 36: ...2 24 2 TIGHTENING TORQUE SERVICE DATA...

Страница 37: ...2 25 2 SERVICE DATA HYDRAULIC CIRCUIT DIAGRAM HYDRAULIC CIRCUIT DIAGRAM Equipped with options 1 2...

Страница 38: ...2 26 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with options 2 2...

Страница 39: ...2 27 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with angle blade and blade oat 1 2...

Страница 40: ...2 28 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with angle blade and blade oat 2 2...

Страница 41: ...2 29 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow option 1 2...

Страница 42: ...2 30 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow option 2 2...

Страница 43: ...2 31 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow angle blade blade oat option 1 2...

Страница 44: ...2 32 2 HYDRAULIC CIRCUIT DIAGRAM SERVICE DATA Equipped with high ow angle blade blade oat option 2 2...

Страница 46: ...2 34 2 ELECTRIC CIRCUIT DIAGRAM SERVICE DATA First auxiliary hydraulic piping with proportional control...

Страница 49: ......

Страница 59: ...2 46 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 60: ...2 47 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 61: ...2 48 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 62: ...2 49 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 63: ...2 50 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 64: ...2 51 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 65: ...2 52 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 66: ...2 53 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 67: ...2 54 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 68: ...2 55 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 69: ...2 56 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 70: ...2 57 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 71: ...2 58 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 72: ...2 59 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 73: ...2 60 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA NAME STANDARD NO...

Страница 74: ...2 61 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 75: ...2 62 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 76: ...2 63 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 77: ...2 64 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 78: ...2 65 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 79: ...2 66 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 80: ...2 67 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 81: ...2 68 2 WIRE HARNESS WIRING DIAGRAM SERVICE DATA...

Страница 92: ...3 11 3 CONTROL VALVE FUNCTION...

Страница 108: ...4 3 4 SERVICE STANDARDS DISASSEMBLY AND ASSEMBLY Clearance for pin and bushing...

Страница 130: ...4 25 4 UPPER FRAME DISASSEMBLY AND ASSEMBLY 15 Side frame R 16 Side frame L 17 Tool box 18 Cover 19 Bracket 20 Cover 2 2...

Страница 165: ...4 60 4 HYDRAULIC PUMP DISASSEMBLY AND ASSEMBLY f Remove the plug g Remove the spring and the ball...

Страница 267: ...4 162 4 SLEW MOTOR DISASSEMBLY AND ASSEMBLY Special tools Oil seal press tting jig A Collar installation jig B...

Страница 352: ...ENGINE 6 Machine model Mounted engine TB250 4TNV88...