16

4.6.5

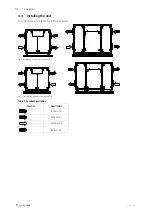

External connections

Table 4 Connections to external functions

Terminal block

Description

Remark

PE

Ground

N

N

Earthed neutral (supply voltage)

Used for phase 230V 1~ and

400V 3~

L1

L1

Phase (Main supply voltage)

Used for phase 230V 1~ if the

unit has this mains

400V 3~/230V 3~

L2

L2

Phase (Main supply voltage)

400V 3~/230V 3~

L3

L3

Phase (Main supply voltage)

400V 3~/230V 3~

1

G

Auxiliary supply (Pressure transmitter. Water

valve actuators)

24V AC

2

G0

Reference (Water valve actuator mains)

24V AC

10

DO ref

DO reference

G (24V AC)

12

1

DO 2

Outdoor/Exhaust air damper

24V AC

Max. 2,0 A continuous load

WP

L1

Circulation pump hot water system

230V AC

14

DO 4

Cooling pump

24V AC

15

DO 5

DX Cooling step 1

24V AC

16

DO 6

DX Cooling step 2

24V AC

17

DO 7

Alarm output for DO signals

24V AC

30

AI Ref

Supply air temperature sensor reference

neutral

31

AI 1

Temperature sensor, supply air

40

Agnd

UI reference

neutral

41

2

UAI 1/(UDI 1)

Pressure transmitter extract air

42

UAI 2/(UDI 2)

Pressure transmitter supply air

44

UAI 3/(UDI 3)

Frost protection sensor water heating

battery

Use terminal 40 as reference

4

DI ref

Extended running/Fire alarm reference

+ 24V DC

P1:50/P2:60

B

Exo-line B

Modbus, Exo-line connection

P:151/P2:61

A

Exo-line A

Modbus, Exo-line connection

P1:52/P2:62

N

Exo-line N

Modbus, Exo-line connection

74

3

DI 4

Extended running

Normally open contact

Use terminal 4 as reference

75

DI 5

Fire alarm

Normally open contact

Use terminal 4 as reference

76

DI 6

External stop

Normally open contact

Use terminal 4 as reference

90

Agnd

AO Reference

neutral

93

AO 3

Control signal valve actuator, Water Heating

0–10V DC

94

AO 4

Control signal valve actuator, Cooling

0–10V DC

1

Maximum current load for all DO combined: 8A

2

Connection to external pressure sensor in case of pressure controlled unit (VAV)

3

These inputs may only be wired to voltage free contacts

4.6.6

BMS Connection

BMS Connection

137667 | A001

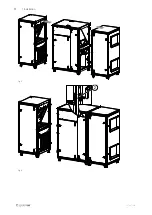

Содержание Topvex SC03-11

Страница 4: ......

Страница 12: ...8 Installation Fig 5 Fig 6 137667 A001 ...