SS-400-012 9 I56-3749-006

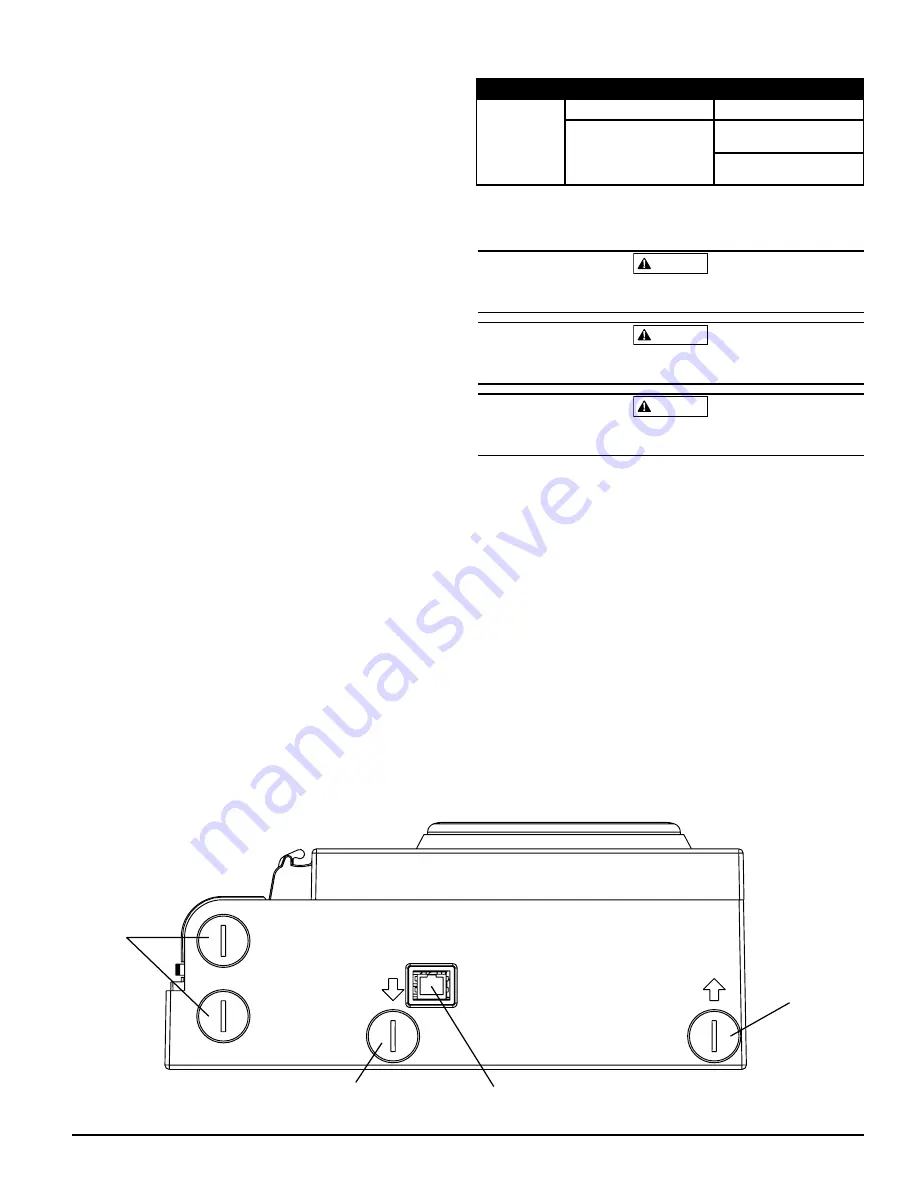

FIGURE 14. BOTTOM VIEW OF UNIT

Wiring

Access

Plugs

Sampled

Air Inlet

Sampled

Air Outlet

Network

Connection

ASP03-00

WEB SERVER

The FAAST system contains an integrated Web server which is used to ob-

serve detector configuration and may be used to remotely monitor the unit.

The Web server features include:

• Intuitive interface for remote monitoring of faults, relays, particulate

level, air flow, and power supply

• Facility location and contact information

• Configuration settings display

• Multi-Lingual support

• Event log viewer

E-MAIL NOTIFICATION

The FAAST system has the ability to send e-mail notifications to an individual

or organization. Up to 6 different email addresses may be stored for notifica-

tion. Each email address can be configured to be notified of a specific alarm

level, fault level or isolate condition through the PipeIQ software. E-mails from

the device indicate a device’s ID, location and alarm or fault type. A com-

prehensive networking guide may be downloaded at systemsensor.com/faast.

CANNED SMOKE TESTING

All FAAST systems must be tested after installation and periodically thereafter.

Testing methods must statisfy the authority having jurisdiction. Systems of-

fer maximum performance when tested and maintained in compliance with

CAN/ULC S536. UL Tested and approved aerosol smoke products are listed

in Table 6.

MAINTENANCE

The only periodic maintenance required is to replace the filter assembly when

the filter light is illuminated. Perform the following procedure to replace the

filter assembly.

1. Remove power from the system.

2. Open the door on the right side of the device that covers the LED system

indicators.

3. Remove the plastic name card over the LEDs.

4. Remove the two screws holding the filter assembly into the device.

5. Remove the filter assembly and replace it with a new assembly.

6.

Install the two screws to hold the filter assembly into the device.

Torque the two Philips head screws to 6 in-lb (0.7 N-m) or 1/4 turn past

“lightly snug”. Do not over tighten.

7. Replace the plastic name card over the LEDs.

8. Close the door and return power to the system.

Other system checks may need to be performed in accordance with local or

national codes and regulations.

CLASS I, DIVISION II

This equipment is suitable for use in Class I, Division 2, Class A, B, C and D

OR non-hazardous environments only.

WARNING

EXPLOSION HAZARD - do not disconnect equipment unless power has been

removed or the area is known to be non-hazardous

WARNING

EXPLOSION HAZARD - Substitution of any components may impair suitabil-

ity for Class I, Division 2

WARNING

Exposure to some chemicals may degrade the sealing properties of materials

used in the relays.

ULC LISTED

COMPANY

AEROSOL

Home Safeguard

25S

No Climb

SOLOA4

SMOKE SABRE-01

TABLE 6. CANNED SMOKE TESTING