SS-400-012 7 I56-3749-006

Alarm Level

Indicator

Particulate Level

Indicator

Power

Indicator

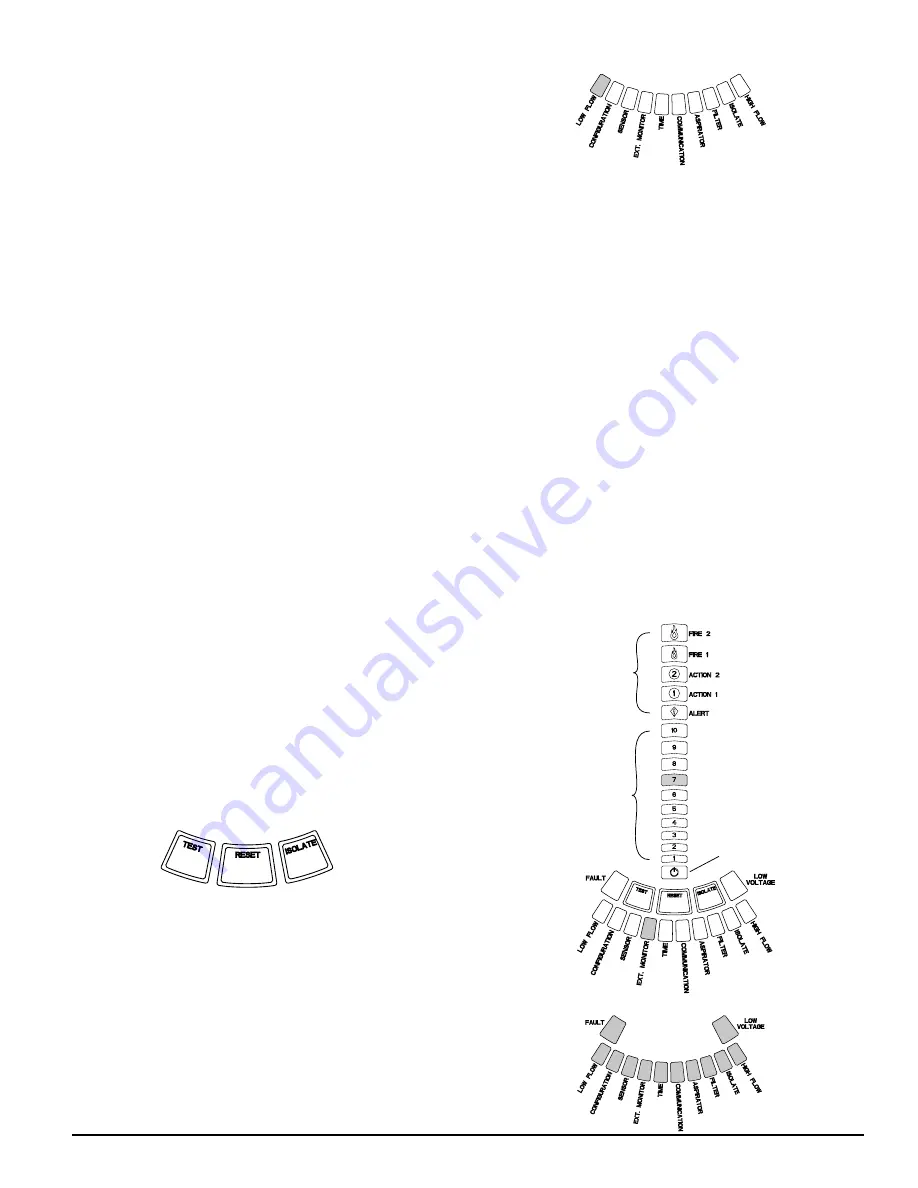

FIGURE 9. PASSCODE ACCESS BUTTONS

ASP11-00

FIGURE 11. IP ADDRESS BLINK MODE

FIGURE 12. IP ADDRESS INDICATOR LIGHTS

ASP15-00

ASP19-00

DAY, NIGHT AND WEEKEND MODE

If Acclimate mode is not desired, the FAAST system can operate in a simple

day, night and weekend mode. This allows the device to have separate thresh-

old levels for each state. Times can be configured, if desired, for entering and

leaving day and night time operation. The device has an internal time refer-

ence (clock) and automatically switches to the weekend mode for Saturday

and Sunday.

ISOLATION

Isolation mode is initiated by pressing and releasing the ISOLATE button on

the user interface when the button is enabled (refer to the passcode section).

When the ISOLATE button is activated the FAAST system resets the fault and

alarm relays. It then sets the isolation relay and the isolation fault indicator

illuminates on the user interface. In this mode the device operates normally

but will not activate relays for any alarm or fault levels (except the Isolation

relay). Fire and fault events can still be seen on the user interface and the web

server will send e-mail notification of events if enabled. Isolation mode will

be held through resets and power outages. The device will remain in isolation

mode until the isolation mode is removed by pressing the ISOLATE button.

ISOLATE mode may be enabled and disabled using the monitoring portion

of PipeIQ.

DISABLE

Disable mode is initiated by pressing and holding the ISOLATE button on the

user interface for 3 seconds when the button is enabled (refer to the passcode

section). When the ISOLATE button is activated, the FAAST system resets the

fault and alarm relays. It then sets the isolation relay and the isolation fault

indicator illuminates on the user interface. In this mode the fan switches off

and the device does not report any alarm or fault levels on the user interface

or activate any relays (except the Isolation Relay). This mode should only

be used when the system needs to be taken offline. This mode will be held

through resets and power outages. The device will remain in disable mode

until the disable mode is removed by pressing the ISOLATE button. Disable

mode cannot be enabled or disabled using the monitoring portion of PipeIQ.

USER BUTTON ALTERNATE FUNCTIONS

Passcode Access

The user interface has an option that requires users to enter a security code

before the front panel functions become active. All passcodes must be 4 digits

in length using numbers 1 through 9 (zero cannot be used). Passcodes may

only be changed through the PipeIQ software program. In addition, the con-

figuration software tool is capable of locking out buttons individually, so that

certain buttons may be accessed without a passcode, if desired.

The default passcode is ‘1111’.

The TEST button enters digits, the RESET button is used to enter the unlock

mode and the ISOLATE button increments the current digit.

To enter the passcode mode, press and hold the RESET button for 8 seconds.

The first segment on the flow indicator first illuminates yellow, then green.

When the segment illuminates green, release the RESET button. The first seg-

ment on the airflow display blinks green, indicating the device is ready to

accept the first digit.

To enter the passcode, use the ISOLATE and TEST buttons, shown in Figure 9.

The ISOLATE button is used to increment the current digit. As the current digit

is incremented the segments of the Particulate Bar Graph illuminate accord-

ingly. To complete entry of the digit, press the TEST button. As each digit is

entered the airflow segment illuminates solid green and the next segment be-

gins to flash, indicating the next digit is ready to be entered. After the 4th digit

is entered, the fault indicator illuminates green, if the passcode was accepted

and remains green as long as the detector is “unlocked”. If the passcode was

not accepted, the fault indicator illuminates amber for 3 seconds then the

device returns to its previous state.

Once the passcode is accepted, the locked out button(s) become active. After 45

seconds of inactivity the fault indicator begins to blink green. After an additional

15 seconds the detector re-locks the button(s) and returns to normal operation.

Note: If the RESET button is chosen as a locked button, and a reset is initiated,

the device requires the passcode to regain access to the RESET button.

Address Blink Mode

The unit has two types of addressing capabilities. In addition to the IP Ad-

dress, the FAAST system can also have a local address that is assigned through

the configuration software. The address can be between 1 and 255. This ad-

dress can be accessed from the user interface by pressing and holding the

RESET button for 3 seconds. After 3 seconds, the first segment on the airflow

display illuminates amber, shown in Figure 10, indicating the device is in ad-

dress blink mode. Release the RESET button and the device shows the 3 digit

number assigned by lighting the particulate bar graph with the appropriate

number of segments for each digit. The current digit displayed is indicated

by the 3 left most indicators on the air flow graph. The first digit is the 100’s

and illuminates for 2 seconds. Next, the tens digit illuminates for 2 seconds,

followed by the ones digit illuminating for 2 seconds. If one of the numbers is

zero, then no lights will illuminate for that number on the particulate graph.

The device then returns to normal operating mode.

IP Address Blink Mode

If the device IP has been lost or is unavailable, it’s possible to obtain the address

using the IP address blink mode. The IP address can be accessed from the user

interface by pressing and holding the RESET button for 30 seconds. The digits are

displayed using the same method described in the address blink mode, except

that the FAULT and LOW VOLTAGE indicators are used to show the 1st and 12th

digit, respectively. The device gives the 12 digit number by illuminating the par-

ticulate bar graph to the appropriate number of segments for each digit, as shown

in Figure 11. The example shown in Figure 11 shows that the 5th number of the

IP address is 7. The current digit displayed is indicated by the FAULT, FLOW /

FAULT and VOLTAGE indicators (figure 12) starting with the FAULT for the 1st

digit, progressing through the HIGH FLOW, and ending with the LOW VOLTAGE

for the 12th digit. If one of the numbers is zero, then no lights will illuminate for that

number on the particulate graph. The device will return to normal operating mode.

FIGURE 10. ADDRESS BLINK MODE

ASP12-00