SS-400-012 6 I56-3749-006

MODES OF OPERATION

INITIALIZATION

When the FAAST system is first installed it is not configured and gives a fault

indication by illuminating the configuration fault LED indicator. This indicates

that the device has not had its initial configuration loaded and remains in this

state until it is initially configured (refer to the Configuration section below for

further instructions). Once configuration has started, the device performs an

automatic initialization. This initialization sets the air flow baseline, the filter

clogged baseline and the particulate level baseline. It is important that the sys-

tem is connected properly and the filter is installed correctly when the device

is initialized. These initial readings are used as a reference baseline to indicate

when a fault occurs. Innitialization may take up to five minutes to complete.

STARTUP

Once powered, the FAAST system scrolls the particulate display in green for

one second and then initializes using its stored configuration. The device

checks and establishes its initial airflow, filter and fan settings. If all measure-

ments are normal it begins normal operation. If any fault is detected the ap-

propriate fault LED will illuminate.

CONFIGURATION

The FAAST system is configured using the software included in PipelQ. Data

is sent via the built-in Ethernet connection. The device receives the configura-

tion and performs a validation before the configuration becomes active. After

validation of the data, the device performs an initialization with the new con-

figuration.

Failure of Configuration Validation

If configuration validation fails, the software configuration tool indicates a

failure and the FAAST system illuminates the amber CONFIGURATION fault

LED on the user interface. The device will not accept any of the data as valid.

If a configuration fault occurs during the initial configuration or the device is

unable to operate due to the configuration, a Major fault relay will be set. The

device must be re-configured using PipeIQ. If the configuration fault occurs

after the initial configuration has been accepted, a Minor Fault relay will be set

and the device reverts back to its last valid configuration.

Power or Network Loss during Configuration

During an upload of configuration data, the FAAST system keeps the last

known valid configuration in memory until a complete validation is com-

pleted on the new configuration data. This prevents data corruption in the

event of a power loss or network failure. When power is restored the device

performs a Startup with the last valid configuration. The device also indicates

a CONFIGURATION fault on the user interface and sets the Minor Fault Relay.

This occurs only once. When the next Reset or Power On Reset is performed

the device continues to use the last valid configuration.

NORMAL MODE

In Normal operating mode the FAAST system displays the air flow and current

particulate levels on the user interface. The particulate level is compared to

the threshold levels programmed into the device and activates the appropriate

alarm as particulate levels exceed that threshold. If any fault occurs it acti-

vates the corresponding fault LED and relay.

TEST MODE

Test mode is initiated through the PipeIQ Live View tab or by depressing the

TEST button on the user interface, when the button is enabled (refer to pass-

code access section for activation details). Test mode simulates a fire con-

dition, activating all ten segments in the Particulate Level display and each

segment in the Alarm display. Each corresponding alarm relay is also acti-

vated after any programmed delay associated with that relay. Activation of the

RESET button removes the device from TEST mode.

RESET MODE

Reset mode is initiated through the PipeIQ Live View tab or by depressing the

RESET button on the user interface, when the button is enabled (refer to pass-

code access section for activation details). When RESET is activated all relays

are reset. The device then enters Normal mode operation. If any fault or alarm

states remain, the device re-activates the state automatically.

ACCLIMATE™

The FAAST system includes an available Acclimate mode. By allowing the de-

vice to operate in Acclimate mode, a device’s susceptibility to nuisance alarms

can be reduced. This provides maximum protection for a device located in

changing environments. The sensitivity of the unit continuously adjusts over

time, within the set limits as the local environment changes. Acclimate mode

must be activated and configured with the software configuration tool which

is part of the PipeIQ software package. In Acclimate mode the device automat-

ically adjusts the alarm point between a specified minimum and maximum

sensitivity, programmed by the user. For the first 24 hours of operation the

device monitors its environment. After the initial 24 hour period, the device

adjusts the alarm point based on the particulate levels over a rolling 1 hour

period. It then adjusts the alarm level starting from the insensitive boundary,

based on the stability of the environment being monitored.

Setting Acclimate mode

The user chooses the boundaries for each alarm level in the Acclimate mode.

The FAAST system starts from the insensitive boundary and adjusts itself to

stay within the sensitive boundary. It is also possible to have a static alarm

level by adjusting the high and low boundary to the same level. This allows

the flexibility to maintain acclimating levels for some alarms and static levels

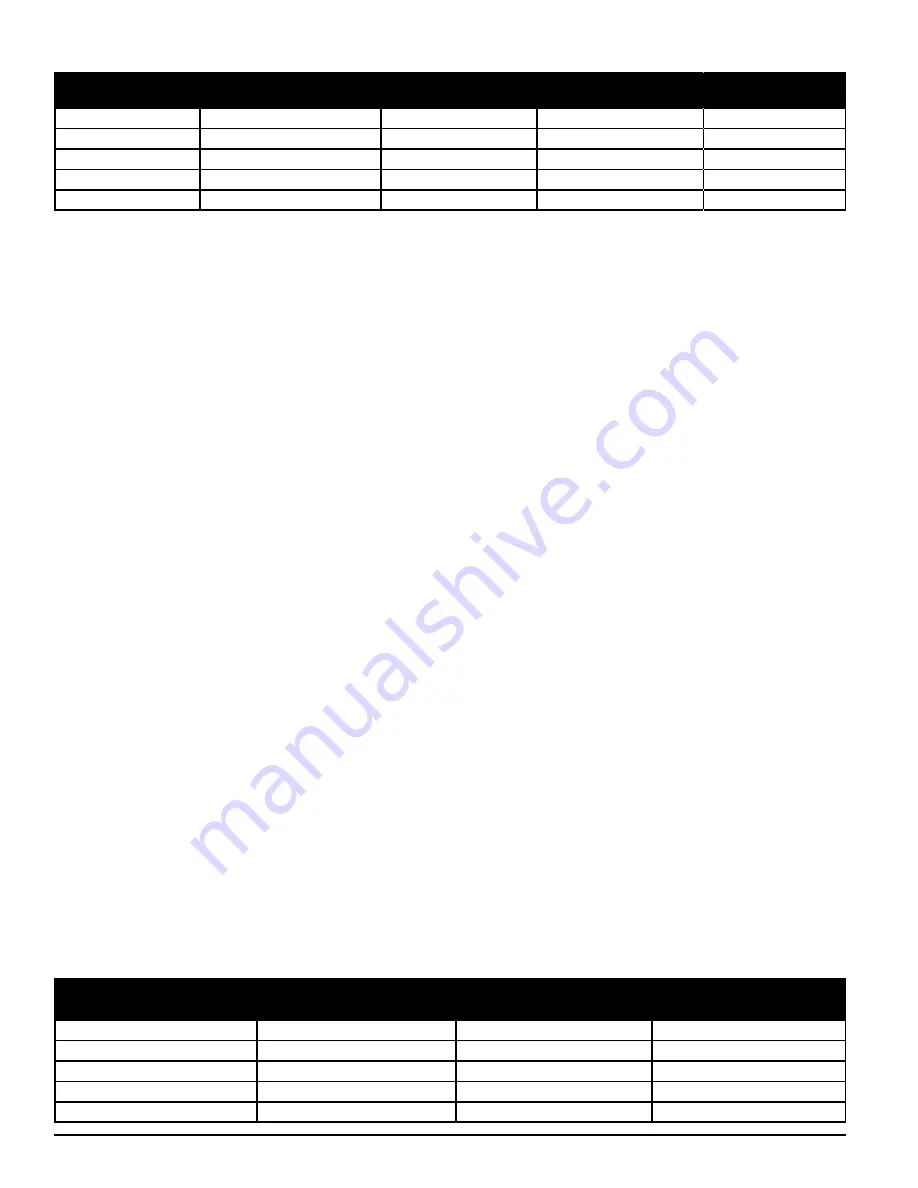

for others. Table 4 shows the various levels that are available.

Each Acclimate level is also available for monitoring with the PipeIQ tool.

This allows the user to read the current Acclimated alarm level for each alarm.

ALARM LEVEL

THRESHOLD HIGH

SENSITIVITY

THRESHOLD LOW

SENSITIVITY

CURRENT LEVEL

Alert

Alert High

Alert Low

Acclimate Alert Level

Action 1

Action 1 High

Action 1 Low

Acclimate Action 1 Level

Action 2

Action 2 High

Action 2 Low

Acclimate Action 2 Level

Fire 1

Fire 1 High

Fire 1 Low

Acclimate Fire 1 Level

Fire 2

Fire 2 High

Fire 2 Low

Acclimate Fire 2 Level

TABLE 4. ACCLIMATE LEVELS

ALARM LEVEL

DEFAULT THRESHOLD

%OBS/FT.

PROGRAMMABLE RANGE

%OBS/FT.

DEFAULT THRESHOLD

%OBS/M

PROGRAMMABLE

RANGE %OBS/M

Alert

0.012

0.00046-6.25

0.0396

0.0015-20.5

Action 1

0.050

0.0010-6.25

0.165

0.0033-20.5

Action 2

0.100

0.0030-6.25

0.33

0.0102-20.5

Fire 1

0.250

0.012-6.25

0.825

.039-20.5

Fire 2

0.500

0.012-6.25

1.65

.039-20.5

TABLE 3. ALARM LEVEL PROGRAMMABLE RANGES

NOTE: Installation must be accomplished in accordance with all local codes and regulations.

Product is ULC certified to CAN/ULC S529. The 8100A FAAST is ULC approved from 0.00046 %/ft obs. to 3.15%/ft obs. Evacuation via FACP (fire alarm control

panel) must not be set higher than 0.735 %/ft obs. Product is approved for air velocity range from 100 to 4000 FPM.