GB.COOLDXS.INS.100507

14 www.swegon.com

We reserve the right to alter specifi cations.

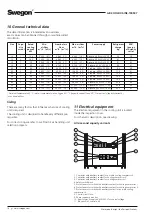

8 Trouble shooting and leakage tracing

8.1 Troubleshooting Schedule

Symptom

Possible cause

Remedial measure

Compressor is not operating

The voltage has been isolated.

Incorrect phase sequence.

The compressor safety circuit has been broken.

Defective cooling compressor.

Check the operating/safety switch. Check the condi-

tion of the fuses.

Check and change the phase sequence.

Check, reset if needed.

Replace the compressor.

Too low cooling capacity

The voltage has been isolated.

Incorrect phase sequence.

No airfl ow or too low airfl ow across the evaporator.

Thermostat/control equipment incorrectly set or

defective.

Check the operating/safety switch. Check the condi-

tion of the fuses.

Check and change the phase sequence.

Check the airfl ow.

Adjust the setting or replace faulty components.

The low pressure switch is swit-

ching off the cooling compressor

Inadequate refrigerant.

No airfl ow or too low airfl ow across the evaporator.

Defective evaporator

The expansion valve is defective.

The high pressure switch is defective.

The cooling system is leaking. Tighten the leak and

charge with refrigerant.

Check the airfl ow.

Check, replace.

Check, replace.

Check, replace.

The high pressure switch is swit-

ching off the cooling compressor

No airfl ow or too low airfl ow across the condenser.

Excessively high ambient air temperature

The high pressure switch is defective.

Check the airfl ow (condenser coil and fan).

Check the ambient air temperature.

Check, replace.

Signifi cant freezing on the

evaporator.

The expansion valve is defective or incorrectly set.

No airfl ow or too low airfl ow across the evaporator.

Defective air cooler

Check. Replace or adjust setting.

Check the airfl ow.

Check, replace.

8.2 Leakage Tracing

Leakage tracing should be carried out at least once per

year as a precaution. The leakage tracing inspection must

be documented.

If the cooling system is leaking, this will become apparent

fi rstly by impaired cooling performance, or if the leakage is

substantial, when the cooling unit does not operate at all.

If you suspect that the cooling system is leaking refriger-

ant, check the level of refrigerant in the sight glass located

on the liquid line of the cooling unit.

If you see continuous and a substantial amount of bub-

bling in the sight glass and the cooling unit operates at ap-

preciably lower capacity than normal, the system is prob-

ably leaking. One or several bubbles appearing when the

cooling unit is started up, operation at reduced capacity or

normal operation need not necessarily indicate a refriger-

ant defi ciency.

If it is bubbling in the sight glass and the cooling unit

operates at appreciably lower capacity, call for qualifi ed

service help.

N.B.! Maintenance work in the refrigerant system is per-

mitted to be carried out only by an accredited inspectorate

(a company with requisite authorisation).