GB.COOLDXS.INS.100507

12 www.swegon.com

We reserve the right to alter specifi cations.

1

1

L1-L2-L3

1

2

34

567

8

9

0

P1

1

2

34

567

8

9

0

P1

5 Commissioning

5.1 Preparations

5.1.1 Before initial start up

•

The power supply should be connected.

•

The communication cable to the GOLD air handling

unit should be connected to one of the connections

marked Internal EIA-485.

•

Check that all the safety switches and motor protec-

tion switches

are set to ON.

The control system of the air handling unit has a pre-pro-

grammed factory setting, which makes the cooling unit

ready for operation when the basic settings have been

performed. The function for the cooling unit should be

activated, see the Operation and Maintenance Instructions

of the GOLD for particulars on how to handle the menus

in the hand-held terminal

5.1.2 Starting up

•

Set the safety isolating switch of the cooling unit to

ON.

•

Check the phase sequence, see Section 5.1.4.

•

Check that light-emitting diode L2 on the IQnomic

Plus module steadily shines (24 V supply), and that

light-emitting diode L1 is fl ashing (communication).

The function switch should be in the position given in

table below section 13 Commissioning Protocol.

•

Check in the hand-held micro terminal of the GOLD

unit that Auto Operation has been selected as the

air handling unit's cooling function (under Operation

Mode), and that Cool DXS has been selected under

Cooling Regulation.

•

Enter the manual test menu via the hand-held termi-

nal of the air handling unit, see the Operation and

Maintenance Instructions of the GOLD.

•

Check: First start the fan, then start one cooling com-

pressor at the time, if any cooling compressor does

not start, an alarm will be initiated.

•

Set the cooling compressors to 0 (stop).

•

Go back to the main menu.

•

The cooling unit is now ready for operation and will

start when there is a cooling load.

5.1.3 Pressure sensor

The cooling unit has two in-service pressure switches in

each cooling circuit, one for low pressure and one for high

pressure.

The compressor is stopped or stepped down when the

operation pressure is outside of the limit values. The text

COOL PRESSURE LIMITING is displayed in the hand-held

terminal until the pressure again comes within limit values.

The compressor is permitted to restart when the restart

delay has expired.

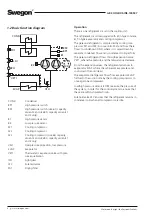

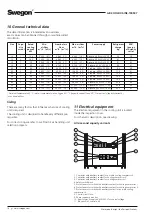

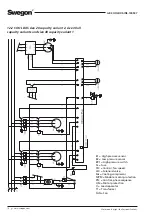

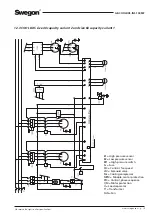

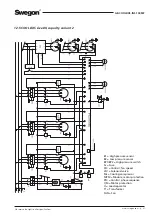

Electrical equipment in the COOL DXS

The phase sequence is correct when LED 1 is lit.

The voltage is connected when LED 2 is lit.

1

2

!

Warning

May only be performed by authorised or trained service

personnel.

5.1.4 Phase-sequence monitor

The cooling unit is equipped with phase sequence monitor

to ensure that the compressors are rotating in the correct

direction.

The phase sequence monitor is installed in the electrical

equipment cubicle, see drawing.

Alarm 164-166, COOL DXS K1-3 tripped, is displayed

in the hand-held terminal of the air handling unit. The

alarms may be due to several causes: incorrect phase se-

quence, tripped high pressure switch (BP2) or the absence

of control voltage.

5.1.5 Measure whether the phase-sequence is wrong

•

Stop the cooling unit by selecting SHUT OFF in the

menu SETTINGS.

•

Set the safety switch to position OFF on the cooling

unit.

•

Isolate the power supply to the cooling unit.

Important

Check that the incoming power supply to the CoolDX is

isolated by measuring.

•

Transpose the two phase wires on the incoming

power supply cable in order to obtain correct phase

sequence (direction of rotation).

•

Connect the power supply to the cooling unit.

•

Set the safety switch to ON.

•

Start the cooling unit as described in the section deal-

ing with starting up, see Section 5.1.2 Starting up.

6 Alarms

For a description of the alarms, see the Operation and

Maintenance Instructions for the GOLD.