0309

TTPM2 Technical Specification

31

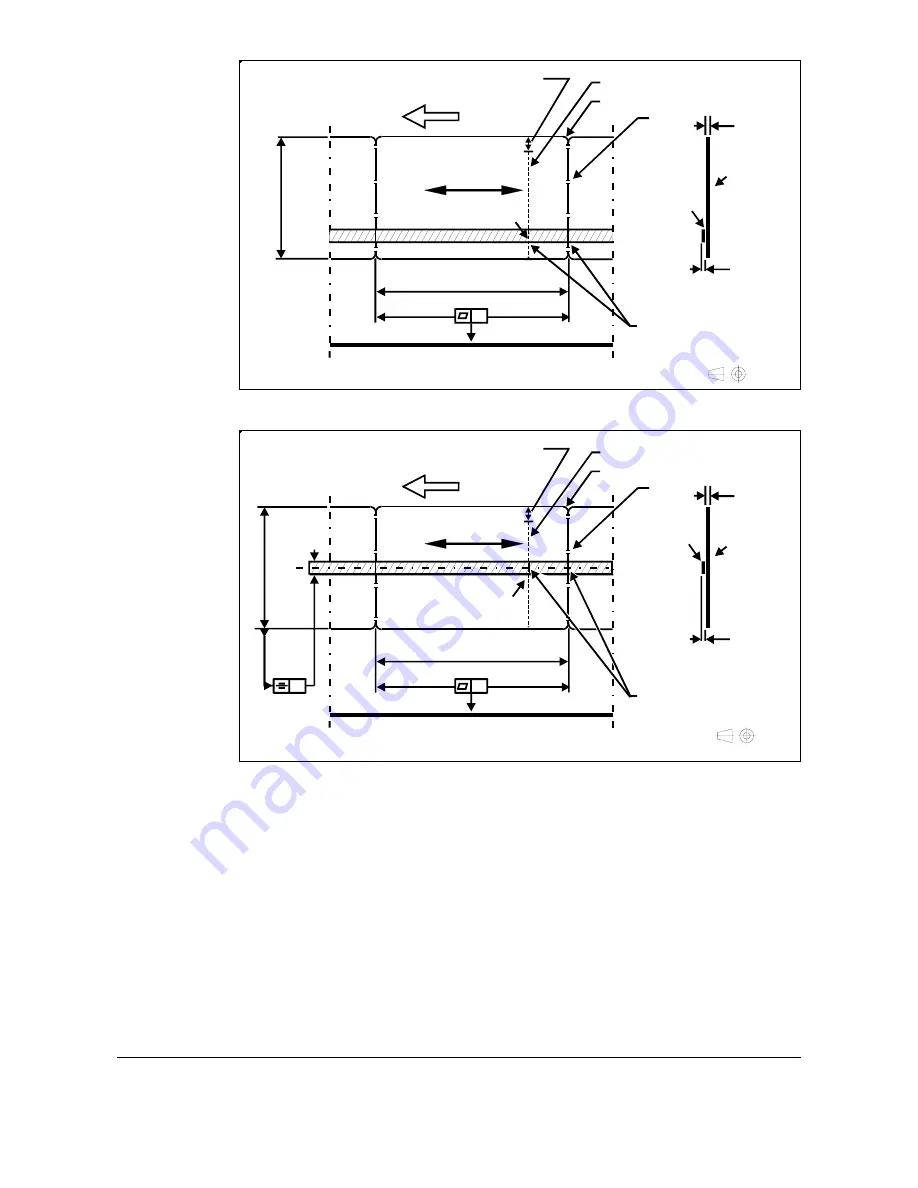

+

Grain direction

Transport

direction

5

3.9

8 ±0

.2

L ±0.25 (see below)

0.6

R 3.15 ±0.3

Thermal

coating

Magnetic

stripe

0.04 max.

0.18 min.

0.4 max.

SW95044C

Stub perforation (if applicable)

Magnetic stripe must be cut

Tabs

L= 85.6 (standard as per ISO 7810)

L= 110.0 (customer special)

6 mm

Perforation not allowed

within this 6 mm wide area

Magnetic code must not

cross optional perforation

Figure 14. Non gapped tickets (for printers with burst separator)

+

Grain direction

Transport

direction

5

3.9

8 ±

0

.2

L ±0.25 (see below)

0.6

R 3.15 ±0.3

Thermal

coating

Magnetic

stripe

0.04 max.

0.18 min.

0.4 max.

Stub perforation (if applicable)

Magnetic stripe must be cut

Tabs

L= 85.6 (standard as per ISO 7810)

L= 110.0 (customer special)

6 mm

Perforation not allowed

within this 6 mm wide area

7.

0 m

m

1

5.

8

2 m

in.

1.0

Magnetic code must not

cross optional perforation

SW95044D

Figure 15. Both gapped and non-gapped tickets with center track can be used in printers ordered with center

track option