5

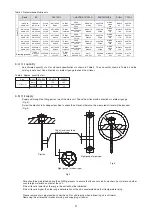

5-1) Installation coupler

. When attaching a coupler, be careful not to apply impact force or excessive

thrust to the shaft ; otherwise, the bearing may be damaged.

. Shrink fit or shaft-end thread is recommended for mounting (Fig. 3)

The dimensions (A, B, and X) illustrated in Fig. 4 shall be within the tolerance

shown in Table 2.

Tolerance for A

dimension

Tolerance for B

dimension

X dimension

0.05mm

0.05mm

0.002in

0.002in

Specified by coupling

manufacturer

Table 2 Aligning tolerance for coupling

Coupler

Shaft

Shaft end thread

Fig. 4

Fig. 3

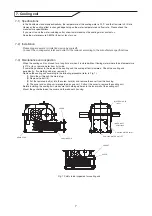

6. Lubrication

6-1) Shipping condition

6-2) Method of lubrication

The oil splash lubrication method is used for PARAMAX SINGLE STAGE DRIVES SPA Series.

Under certain conditions, grease or forced lubrication should be used.

(1) Splash lubrication

(2) Forced lubrication

(3) Grease lubrication for bearings

Standard input shaft rotating speed range 450 1800r/min.

Grease lubrication will be required depending on an operating condition. In such case, the location and number of

grease nipples should be confirmed in advance. The bearings are packed with grease at the time of shipment.

Supply grease according to the input speed - every 1500 hours when the revolution is under 750r/min, and every

1000 hours when the revolution is 750-1800r/min.

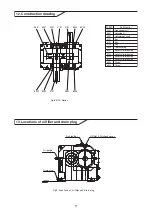

6-3) Selection of lubricant

Refer to Table 3 to select mineral oil or synthetic oil.

Table 4 shows recommended lubricants.

. PARAMAX SINGLE STAGE DRIVES SPA Series units are shipped without oil. Supply recommended oil

before operation.

Table 3 Lubricant table

CAUTION

For a system in which a lubricant motor pump is provided separately, switch on the pump motor prior to

switching on the reducer motor. This will enable proper lubrication of the bearings prior to start up.

Failure to do so may damage the unit.

Use a flow switch and/or sight to verify that lubricant is circulating, and for emergency motor stop if necessary.

X

X

A

B

Ambient temperature

100 r/min or more

ISO* AGMA

*Kinetic Viscosity (cSt) at ISO 40 C

VG68 2EP

VG150 4EP

VG220 5EP

100 r/min or less

ISO* AGMA

VG100 3EP

VG220 5EP

VG320 6EP

Output speed

- 10 C to +15 C

+10 C to +50 C

0 C to +30 C

Содержание PARAMAX SPA Series

Страница 14: ......