10

10. Troubleshooting

When any abnomality occurs in the reducer, refer to the following table and take appropriate measures as soon as

possible. If they are not repairable, contact the nearest agent, distributor or service office.

Details of trouble

The input shaft rotates, but the output

shaft will not.

Damage due to overloaded gears or

shafts

The key is out of position

Scorched bearing

Poor adjustment of protective device

Incorrect wiring for the motor

Overload

The ambient temperature is too high

Damage due to overload applied to

gears, bearings, etc.

Reduce the load to the specified value

Improve the ventilation method

Damaged gears, shafts, or bearings

Repair at a specialized workshop

Deformation of the housing due to

irregular installation surface

Flatten the installation surface or use

liners for adjustment

Repair at a specialized workshop

Damaged oil seal

Scratches or abrasion of the lip contact

section

Loose tightening bolt

Tighten the tightening bolts to the proper

torque

Change the oil seal

Repair at a specialized workshop

Repair at a specialized workshop

Place the key in position

Repair at a specialized workshop

Adjust the protective device

Change the connection

The output

shaft turns

when there is

no load.

Excessive temperature rise

Oil leakage

Abnormal sound.

Excessively high vibration.

Oil leaks from the input /

output shaft sections.

Oil leaks from the joint

surface of the housing.

But it seizes up when a

load is applied.

Reverse rotation is possible.

Cause

Correction

Scorched bearing

Repair at a specialized workshop

Resonance due to insufficient rigidity of

installation base

Reinforce the installation base to

improve the rigidity

Incorrect alignment with the mating machine

Align the shaft center

Transmission of the vibration of the

mating machine to the reducer

Independently operate the reducer to

check the source of abnormal sound

Table 8

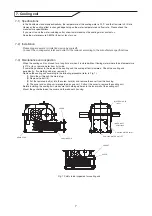

11. Disassembly / reassembly and disposal

11-1) Disassembly and reassembly

11-2) Disposal

CAUTION

Repair, disassembly, and reassembly should be handled by properly trained technicians ; otherwise, the

system may be damaged.

CAUTION

CAUTION

Dispose the reducer and lubricant as general industrial waste.

Promptly identity and correct, according to instructions in this maintenance manual, any abnormalities

observed during operation. Do not operate until abnormality is corrected.

Содержание PARAMAX SPA Series

Страница 14: ......