9

9. Daily inspection and maintenance

DANGER

Never approach or touch any rotating parts (shaft, etc.) when maintaining or inspecting the reducer during

operation.

Loose clothing cought in these rotating parts may result in severe injury and/or death.

Be sure to stop both the driving and driven machines before checking any tooth surfaces; otherwise, you may

be caught in the gear engaging section, resulting in severe injury and/or death.

Do not operate any units without all (safety) covers in place. Failure to do so may cause injury and/or death.

CAUTION

The surface of the reducer will get hot, do not touch the reducer ; otherwise, a burn may result.

Do not change the oil during operation or soon after operation has ceased ; otherwise, the hot oil may cause

burns.

Do not remove any covers or open the reducer during operation ; otherwise, splashing hot lubricant may

cause burn.

Change lubricant according to the maintenance manual, and use only those recommended lubricants ;

otherwise, the system may be damaged.

Do not operate damaged PARAMAX SINGLE STAGE DRIVE SPA Series; otherwise, injury, fire, or damage

to the system may result.

We cannot assume any responsibility for damage or injury resulting from an unauthorized modification by a

customer.

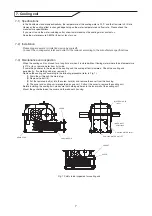

9-1) Daily inspection

To ensure proper and contined optimum operation, use the table below to perform daily inspections of the unit.

When any abnomality is found during daily inspection, take appropriate corrective measures based on "10.

Troubleshooting (P.10)"

If normal operation is still not possible, contact the nearest agent, distributor, or service office.

Inspection item

Noise

Vibration

Surface

temperature

Oil level

Oil leakage

Foundation bolt

Details of inspection

Is there abnormal sound or sudden change in the noise characteristics during

operation ?

Is there any abnormal vibration or sudden change in the vibration of the

reducer?

Is the temperature of the surface of the reducer abnormally high ? Or is it

rising rapidly?

The temperature rise during operation differs according to the type of

reducers. A surface temperature of approx. 80 C (176 F)will not cause

any adverse effects as long as it does not rise significantly above this level.

Is the oil level decreasing ?

(Check the oil level with a dipstick or visible oil gauge when the reducer is not

operating)

Is oil leaking from the oil seal or other sections?

Have any bolts come loose ?

Table 7

9-2) Change of lubricant

Table 8 Oil change interval

Please consult lubrication supplier when atmosphere is contains corrosive gas or where ambient temperature

changes dramatically.

Oil feeding

Oil change

Whichever comes sooner, after 500 hours or six months of operation

Whichever comes sooner, after 2,500 hours or six months of operation

Whichever comes sooner, every 5,000 hours or each year

Whichever comes sooner, every 2,500 hours or each year

1st time

2nd time

3rd time

or later

Interval

At purchasing

Usage conditions

When case oil temperature is lower than 70 C

When case oil temperature is 70 C or higher

Содержание PARAMAX SPA Series

Страница 14: ......