18

(176ºF) / the lower bearings to 110ºC (230ºF) with an

induction heater or LP-gas. Angular contact ball bear

-

ings should be mounted only by pressing on the inner

ring.

Top bearings on J 205-J 604 are type sealed and pre-

filled with high temperature grease for life time perfor

-

mance.

Lower bearings on J 205/J 405 are type sealed and

pre-filled with high temperature grease for lifetime per

-

formance.

Lower bearing on J 604 is type open and should be

filled to 65% with SKF LGHP-2 high performance

grease for lifetime performance.

Note!

Bearings must be filled in a clean environment avoiding

dirt to come into the bearing.

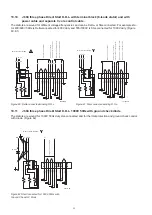

J 205:

Lift the rotor with top/bottom bearing and bear-

ing cover mounted (Can be lifted manually) and slip it

smoothly in to the bearing seat on the oil casing. Mount

the screws on the bearing cover. Mount the circlip and

the washer on the shaft below the lower bearing. (Fig-

ure 30)

J 405:

Lift the rotor with bottom bearing and bearing

cover mounted. Mount a lifting bow on the top bearing

seat to lift the rotor and slip it smoothly in to the bearing

seat on the oil casing. Then mount the top bearing on

the shaft with assembly tool. Mount the screws on the

bearing cover. Mount the circlip on the shaft below the

lower bearing. (Figure 30)

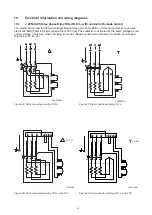

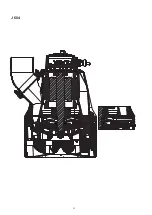

J 604

: Lift the oil casing with bearing seat facing up-

wards and place it on a frame which allows enough

space to assemble the rotor into the oil casing. (The

cooling jacket turned upside down can be used as sup-

port frame). Mount a lifting bow on the top bearing seat

on the shaft, then lift the rotor unit and lower it into the

bearing seat on the oil casing. Heat the bearing seat

with LP-gas to approx.150ºC (302ºF) to easy slip the

lower bearing into place. Mount the screws on the bear-

ing cover. Mount the washer and the circlip on the shaft

below the bearing. (Figure 31)

Turn the rotor by hand and check that it turns freely

without seizing

Check the conditions of the bearing sensors and leak-

age sensors. It is important that leakage sensor seals

the motor chamber from the oil chamber.

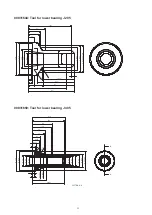

Figure 30: Mounting of ball bearing (J 205, J 405)

Figure 31: Mounting of ball bearing (J 604)

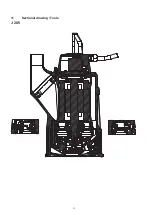

Figure 32: Mounting of motor housing (J 205, J 405)

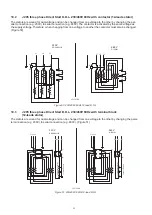

9.5

Motor housing & rotor unit with

oil casing

J 205:

Grease and mount the o-ring on the oil casing

and check that the o-ring in the upper bearing seat in

the motor housing is in place OK. Lift the assembled

motor housing in the lifting chain/wire and lower it onto

the rotor unit. Put a distance piece between motor

housing and oil casing so leakage sensor cable can be

connected. Lower it carefully on to the oil casing. Mount

the nuts and tighten them firmly. (Figure 32)

J 405:

Grease and mount the o-ring on the oil casing

and check that the o-ring in the upper bearing seat in

the motor housing is in place OK Lift the assembled

Содержание J 205

Страница 1: ...en www sulzer com Submersible Drainage Pump J 205 J 405 J 604 Workshop Manual 00831887 02 2020 ...

Страница 30: ...30 11 Sectional drawing Tools J 205 ...

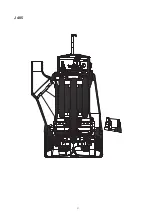

Страница 31: ...31 J 405 ...

Страница 32: ...32 J 604 ...

Страница 37: ...37 ...