13

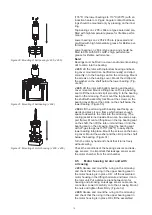

7.4

Motor housing

It is advisable to mount the oil plugs back on the oil cas-

ing to avoid unnecessary spill of oil.

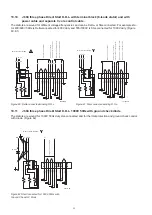

J 205:

Mount a lifting chain/wire with two screws on the

upper part of the motor housing and keep it in an up-

right position secured by the lifting crane. Unscrew the

nuts holding the motor housing/oil casing together and

lift off the motor housing. (Disconnect the cable for the

leakage sensor). (Figure 16)

J 405:

MOUNT THE HANDLE BACK TO THE MOTOR

HOUSING. Use a lifting crane to lift the pump in the

handle to an upright position standing on the stud bolts.

Unscrew the nuts holding the motor housing (use a pipe

tong to contra hold the diffuser stud bolts) and lift off

the motor housing separating it from the rotor/oil casing

package (Disconnect the cable for the leakage sensor ).

(Figure 16)

J 604:

Keep the pump secured by the lifting eye bolt on

the shaft end and the lifting crane. Disconnect the cable

for the leakage sensor and bearing sensor. Unscrew the

nuts and lift off the oil housing together with the rotor +

shaft from the motor housing. Release the seal leakage

monitor plug out of its rubber housing and the lower

bearing monitor plug out of the bearing flange. (Figure

17)

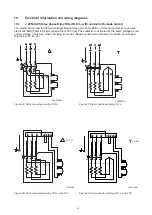

7.5

Rotor + shaft and ball bearings

J 205

: Keep the rotor unit standing upright and un

-

screw the lower bearing bracket. Lift out the rotor with

bearings from the oil casing (Can be lifted manually or

alternatively a lifting strap can be attached to the upper

bearing). Use a bearing puller to remove both bearings

from the shaft (Use a long arm puller for the lower bear-

ing). (Figure 18)

J 405:

Lift the rotor unit standing upright and unscrew

the lower bearing bracket. Remove the upper bearing

with a puller and mount a lifting bow on the shaft end

and lift out the rotor from the oil casing. (Alternatively a

lifting strap can be attached to the upper bearing to lift

out the rotor from the oil casing). Use a bearing puller

with long arms to remove lower bearings from the shaft.

(Figure 18)

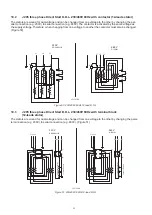

J 604:

Dismantle the oil housing from the rotor + shaft

completely. Unscrew the screws on the bearing flange.

Place the oil housing on the auxiliary tool on the press.

Press out the rotor + shaft with the lower bearing of the

oil housing. The bearing seat can be heated quickly

with LP-gas to facilitate the removal. (Figure 19)

Hint!

Make sure the oil casing is well supported on the

press when the rotor with bearings is pressed out. This

is to avoid unwanted changes on the bearing seat on

the oil casing.

Hint!

Place a hard rubber sheet under the table in order

to avoid damage to rotor shaft and upper bearing.

Remove the circlip under the lower ball bearing. Lay

the rotor + shaft down on the side. Use a bearing puller

with long arms to remove lower bearings from the shaft.

Figure 16: Removal of motor housing (J 205, J 405)

Figure 17: Removal of motor housing (J 604)

Figure 18: Removal of rotor unit (J 205, J 405)

Figure 19: Removal of rotor unit (J 604)

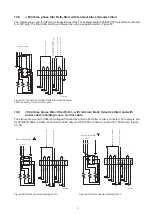

Содержание J 205

Страница 1: ...en www sulzer com Submersible Drainage Pump J 205 J 405 J 604 Workshop Manual 00831887 02 2020 ...

Страница 30: ...30 11 Sectional drawing Tools J 205 ...

Страница 31: ...31 J 405 ...

Страница 32: ...32 J 604 ...

Страница 37: ...37 ...