22

EN/06.2016/i01 © STULZ S.p.A. – all rights reserved

WPA ExPlOrEr OrIGINAl INSTrUCTIONS

There are two main sources which are responsible for the noise. One is the fan section and the

other one is the compressors. To reduce the noise caused by the fans the fan speed of the low

noise version is reduced by changing the electrical connections from delta to star. This occurs in

a reduction of the fan speed of approx. 30%. In some cases a greater surface of the condenser

is requested and therefor an additional V-module is added.

To reduce the noise emitted by the compressors they are installed in a completely insulated

compressor compartment.

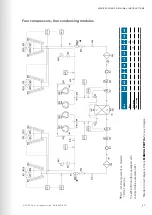

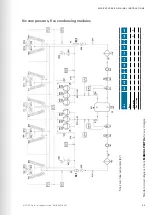

4.3.3 refrigerant Circuit

Two independent refrigerant circuits are provided. Each circuit uses copper refrigerant pipes that

are formed on computer controlled bending machines where possible to reduce the number of

single point of failures and to provide a reliable and leak resistant system.

An electronic expansion valve is also part of the standard equipment as well as a filter dryer with

replaceable cartridge and a sight glass with humidity indication.

Each refrigerant circuit disposes of the following safety devices:

low pressure switch

A low pressure switch is installed in each cooling circuit. It will be activated when the pressure

inside the cooling circuit drops down to 2.4 barg. The compressors of the circuit will be turned

off and an alarm signal is shown on the electronic control display. The pressure switch needs to

be reset manually.

High pressure switch

A high pressure switch is installed in each cooling circuit. It will be activated when the pressure

inside the cooling circuit exceeds 40.5 barg. The compressors of the circuit will be turned off

and an alarm signal is shown on the electronic control display. The pressure switch needs to be

reset manually.

Safety valve

A safety valve is installed in each cooling circuit. It is positioned on the pressure side of the

compressor. The safety valve will be activated when the pressure in the cooling circuit exceeds

the max. value of 45 barg. (Whether the chiller is operating or not.) In this case the safety valve

opens and the refrigerant will exit.

4.3.4 Compressor

The chiller has hermetic scroll compressors. Depending on the size there are either four or six

compressors installed in in a compressor compartment in the unit, i.e. two or three per refriger-

ant circuit, which can be separately switched on and off. In combination with the possibility to

individually operate the refrigerant circuits the total cooling capacity can be graded in steps of

25% resp. 12.5%. The compressor contains a crankcase heater.

4.3.5 Evaporator

The Explorer WPA 060 – WPA 140 is equipped with a brazed welded heat exchanger made of

AISI 316 and AISI 304 stainless steel. The sizes Explorer WPA 160 – WPA 200 are supplied

with a shell & tube heat exchanger made with copper pipes and steel shell.

4.3.6 Condenser

The air cooled condensers are MicroChannel condensers completely made of aluminium real-