57

© STULZ S.p.A. – all rights reserved EN/06.2016/i01

WPA ExPlOrEr OrIGINAl INSTrUCTIONS

WArNING

Do not add any other fluids or additives to the filling liquid except those provided. Do not

mix any products and/or additives of different brands

For additional freeze protection at low ambient temperatures consider using the optional electri-

cal heaters.

The following additional components are necessary for the external hydraulic circuit:

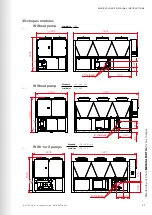

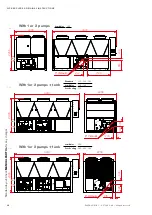

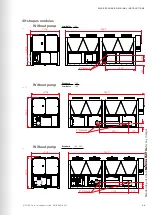

• Suitable connection pipes according to the drawings in this chapter.

• Stop off valves upstream the chiller to be able to take the chiller unit out of the chilled water

circuit in case of service and maintenance work without draining the entire circuit.

• Air relief valve at the highest point of the circuit.

• Filling valve at the lowest point of the circuit.

• Mesh strainer in the chilled water inlet with mesh size of 800 μm for units with plate heat

exchanger (WPA060 to WPA140) and mesh size of 1600 μm for units with shell and tube

evaporator (WPA060 to WPA200).

• An appropriate insulation of the pipework to prevent condensate formation.

If the chiller is not provided with the following components, the external hydraulic circuit must be

equipped with them additionally:

• Circulating pump with sufficient delivery height according to the minimum and maximum flow

rates and corresponding pressure drop which can be found in chapter "5.4 Technical Data" at

page 30 .

• Expansion tank with safety valve to ensure a possibility of expansion for the liquid at tempera-

ture variations. The expansion tank must be dimensioned in such a way that the water circuit

volume can increase by 2% without draining off liquid through the safety valve.

• Storage tank as an accumulator for heat energy to reduce the on/off cycles of the compressor.

A storage tank is recommended if the water volume of the water circuit is less than 9 liters/kW

cooling capacity for the 4-compressor units and less than 6.5 liters/kW cooling capacity for

the 6-compressor units. The storage tank should be lined out with thermal insulation.

WArNING

Even with a built-in storage tank the heat load should not be less than half the minimum

cooling capacity of the unit.

In addition to the differential pressure switch, a flow switch can be installed in the outlet of the

hydraulic circuit as an additional protection device for the evaporator, measuring whether the

fluid is circulating.

DANGEr

The discharge of the safety valve must be positioned in a proposed area so that the leaving

fluid will not endanger persons.

Model

WPA 060 - 140

WPA 160 - 200

Drain connection of the safety valves

3/4" G male

1 1/4" G male