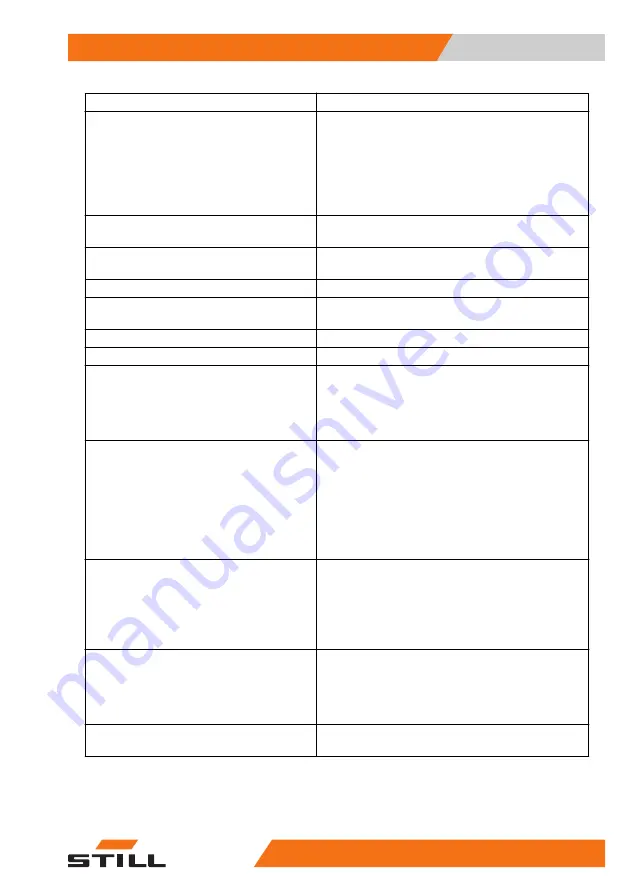

Component

Course of action

Attachments (variant)

Ensure the attachments are mounted correctly in

accordance with the operating instructions of the

manufacturer.

Perform a visual inspection to ensure the attach-

ments are intact and not leaking.

Perform checks to ensure the attachments are

working correctly.

Underside

Check the area under the truck for leaking consum-

ables.

Overhead guard, guard grille (variant)

Perform a visual inspection for integrity.

Check for secure mounting.

Steps

Make sure they are clean (free of ice, not slippery).

Panes of glass (variant)

Perform a visual inspection for integrity.

Make sure they are clean (also free of ice).

Handholds

Check for secure mounting.

Maintenance lids

Check the close function and close the lids.

Battery

Perform a visual inspection for integrity and defor-

mation.

Check that the battery tray is securely and correctly

seated on the battery base frame.

The battery must be level.

Battery connection assembly

Check the battery male connector, the plug connec-

tion and the contacts for integrity and deformation.

Have any damaged or deformed components re-

placed by the authorised service centre.

Inspect the battery male connector and the plug

connection for moisture or for any foreign objects

that may have become lodged. Remove any mois-

ture or foreign objects, e.g. using compressed air.

Battery cover

Perform a visual inspection for integrity and defor-

mation.

Check the condition and function of the quick re-

lease clamp, the handles, the interlock and the

latch.

Check the close function and close the cover.

Battery rack

Perform a visual inspection for integrity and defor-

mation.

Detent cams in the battery compartment must be

fully engaged in the bores of the battery base

frame.

Battery lock

Check the condition and function.

Swivel the battery lock all the way down.

Operating

4

Checks and tasks before daily use

73

56358042501 EN - - 11

Содержание RX60-60

Страница 2: ......

Страница 13: ...1 Foreword ...

Страница 20: ...Overview Foreword 1 Your truck 8 56358042501 EN 11 ...

Страница 41: ...2 Safety ...

Страница 55: ...the truck correctly and without the risk of acci dents Safety 2 Residual risk 43 56358042501 EN 11 ...

Страница 70: ...Safety 2 Emissions 58 56358042501 EN 11 ...

Страница 71: ...3 Overviews ...

Страница 83: ...4 Operating ...

Страница 231: ... Load capacity Q kg 1 Lift height h mm 2 Load distance C mm 3 Operating 4 Attachments 219 56358042501 EN 11 ...

Страница 336: ...Operating 4 Decommissioning 324 56358042501 EN 11 ...

Страница 337: ...5 Maintenance ...

Страница 344: ...Maintenance 5 General maintenance information 332 56358042501 EN 11 ...

Страница 381: ...6 1000 hour maintenance annual mainte nance ...

Страница 384: ...1000 hour maintenance annual maintenance 6 Checking the reversible fork arms 372 56358042501 EN 11 ...

Страница 385: ...7 Technical data ...

Страница 398: ...Technical data 7 Fuse assignment 386 56358042501 EN 11 ...

Страница 407: ......

Страница 408: ...STILL GmbH 56358042501 EN 11 ...