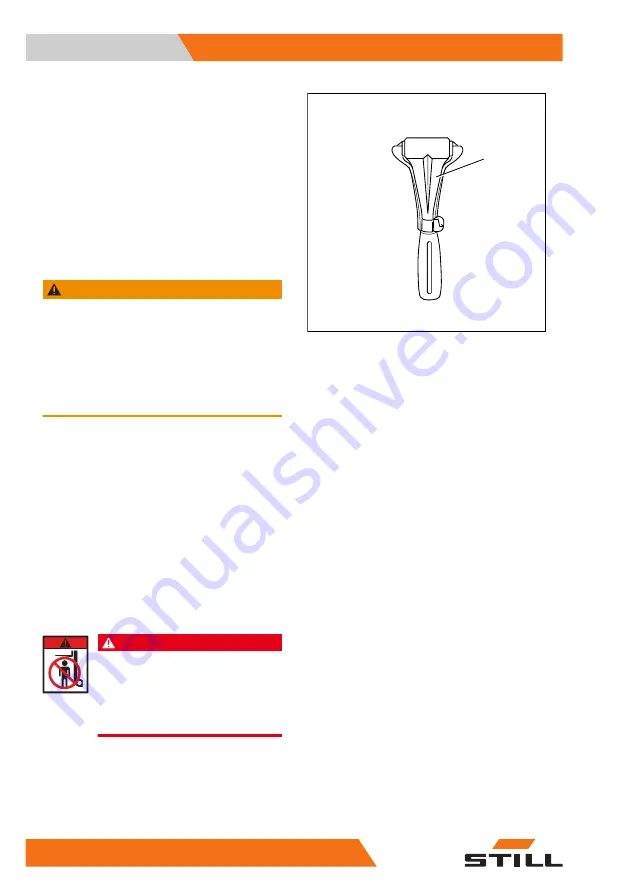

Emergency hammer

The emergency hammer is used to rescue the

driver if he is shut inside the cab in a hazard-

ous situation, for example if the truck has top-

pled over and the cab door cannot be opened.

Single-pane safety glass can be struck rela-

tively safely using the emergency hammer in

order for the driver to escape or be rescued

from the danger area.

Using the emergency hammer

WARNING

When glass is smashed there is a risk of injury

caused by glass splinters!

When the cab glass is smashed, splinters of glass

can shoot into the face and cause damage to skin

and eyes through cuts. When a pane of glass is

smashed, the face should be turned away and cov-

ered with the crook of the free arm.

–

Protect the face when smashing a pane of glass.

–

Pull the emergency hammer out of its sup-

port mounting at the handle.

–

Using one of the two metal tips on the head

of the emergency hammer, hit the pane of

glass with force until it breaks.

Emergency lowering

If the hydraulic controller fails whilst a load is

raised, emergency lowering can be performed.

An emergency lowering screw for this purpose

is located on the control block.

DANGER

There is a risk of fatal injury from falling

loads or parts of the truck being low-

ered.

–

Do not walk beneath the raised load.

–

Follow the steps described below.

6321_003-097_V3

1

Operating

4

Procedure in emergencies

306

56358042501 EN - - 11

Содержание RX60-60

Страница 2: ......

Страница 13: ...1 Foreword ...

Страница 20: ...Overview Foreword 1 Your truck 8 56358042501 EN 11 ...

Страница 41: ...2 Safety ...

Страница 55: ...the truck correctly and without the risk of acci dents Safety 2 Residual risk 43 56358042501 EN 11 ...

Страница 70: ...Safety 2 Emissions 58 56358042501 EN 11 ...

Страница 71: ...3 Overviews ...

Страница 83: ...4 Operating ...

Страница 231: ... Load capacity Q kg 1 Lift height h mm 2 Load distance C mm 3 Operating 4 Attachments 219 56358042501 EN 11 ...

Страница 336: ...Operating 4 Decommissioning 324 56358042501 EN 11 ...

Страница 337: ...5 Maintenance ...

Страница 344: ...Maintenance 5 General maintenance information 332 56358042501 EN 11 ...

Страница 381: ...6 1000 hour maintenance annual mainte nance ...

Страница 384: ...1000 hour maintenance annual maintenance 6 Checking the reversible fork arms 372 56358042501 EN 11 ...

Страница 385: ...7 Technical data ...

Страница 398: ...Technical data 7 Fuse assignment 386 56358042501 EN 11 ...

Страница 407: ......

Страница 408: ...STILL GmbH 56358042501 EN 11 ...