Digi 20 Series

One Circuit Electronic

24 Hour or 7 Day Time Switches

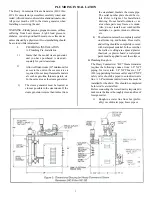

FIGURE 7. Auto Blowdown and Auto ON/OFF Timeclock

Digi 20A

(surface mounting)

Operating Instructions

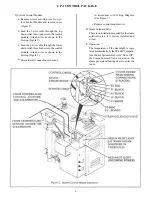

APPLICATION

Time based control of lighting, ventilating, heating, cooling or other electrical loads in commercial and industrial applications. The Digi 20 time

switches are programmable for 24-hour or 7-day schedules.

The Digi 20A is intended for either surface or rail mounting. The control is completely enclosed in a plastic housing and includes a terminal

cover and sub-base for installation and hard wiring.

The Digi 20E is intended for flush (panel) mounting.

All units are supplied with a clear plastic dust cover.

TECHNICAL DATA

Output-1 SPDT relay with dry contacts

Switch Rating: 16A/277VAC resistive

1 OOOW tungsten @ 240VAC; 50OW @ 120VAC

1/2 hp @ 120VAC; 1 hp @ 240VAC

100 hour capacitor back-up of memory and display

Supply voltages: Separate Models - 24VAC/DC, 120VAC,

208/240VAC, all 50/6OHz (refer to product label)

Shortest switch time-1 minute

Ambient Temperature Range -20 F to 140 F ( 28

C to 60 C)

VA required: 120V & 240V models: 4VA

24V model: 2VA @ 24VAC, 1VA @ 24VDC

Screw terminal connections (Digi 20A)

1/4" quick connects (Digi 20E)

Accuracy ± 4 minutes per year

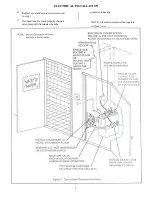

WIRING

1. Disconnect the power.

2. Wire input to timer M to the proper

voltage marked on the unit. Wiring to

incorrect voltage will avoid the warranty.

3. Connect wiring according to the wiring

diagram. The terminals on the Digi 20A

sub base will accommodate 10 to 24 AWG

wire.

Mechanical Timer Shown

9

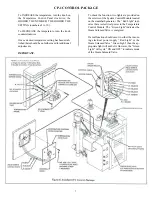

Содержание HC-10

Страница 1: ...HEAVY COMMERCIAL STEAMBATH GENERATOR OWNERS MANUAL Models HC 9 Thru HC 18 3 98 Pub No 400 G ...

Страница 12: ......

Страница 13: ......

Страница 14: ......