ENGLISH • 15

USING AN EXTENSION CABLE

If it is necessary to use an extension cable, please used an

ap- proved extension cable that fits the tool’s power input

specifica- tions (please refer to the technical data). The

minimum cross- sectional area of the conducting wire is

1.5 sq. mm. Cables should be untangled before reeling up.

Please refer to the following table.

Conductor size (mm

2

)

Cable rating (Amperes)

0.75

6

1.00

10

1.50

15

2.50

20

4.00

25

Cable length (m)

7.5 15 25 30 45 60

Voltage Amperes Cable rating (Amperes)

115

0 - 2.0

6 6 6

6 6 10

2.1 - 3.4

6 6 6

6 15 15

3.5 - 5.0

6 6 10 15 20 20

5.1 - 7.0

10 10 15 20 20 25

7.1 - 12.0

15 15 20 25 25 -

12.1 - 20.0

20 20 25 -

- -

230

0 - 2.0

6 6 6

6 6 6

2.1 - 3.4

6 6 6

6 6 6

3.5 - 5.0

6 6 6

6 10 15

5.1 - 7.0

10 10 10 10 15 15

7.1 - 12.0

15 15 15 15 20 20

12.1 - 20.0

20 20 20 20 25 -

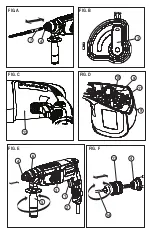

FEATURES (Fig. E)

This tool includes some or all of the following features.

1. Variable speed switch

2. Lock-on button

3. Mode selector

4. Tool clamp

5. Side handle

6. Depth stop

ASSEMBLY

Warning! Before assembly, make sure that the tool is

switched off and unplugged.

Attaching the Side Handle (Fig. E)

Warning! When drilling holes in concrete or bricks,

please use the side handle for your safety.

f

Turn the grip counterclockwise until you can slide the

side handle onto the front of the tool.

f

Rotate the side handle into the desired position.

f

Tighten the side handle by turning the grip clockwise.

Warning! When using the tool, remember to install the

side handles properly.

Fitting an accessory (Fig.A)

f

Clean and grease the shank (7) of the accessory.

f

Insert the accessory bar into the tool clamp (4).

f

Push the accessory down and turn it slightly until it fits

into the slots.

f

Pull on the accessory to check if it is properly locked.

The hammering function requires the accessory to be

able to move axially several centimetres when locked

in the tool clamp.

f

To remove the accessory, pull back the sleeve (8)

and pull out the accessory tool clamp.

USE

Warning! Please operate tool with normal load. Do not

over- load.

Warning! Before drilling into walls, floors or ceilings,

check for the location of wiring and pipes.

Selecting the operating mode (Fig. B)

The tool can be used in two operating modes. Based on

actual work requirements, the drilling mode selector (3)

can be rotated to the required position.

Hole Drilling (Fig. B and F)

f

For drilling in steel, wood and plastics, set the

operating mode selector (3) to the position. At the

same time, it is necessary to use a suitable drill chuck

(13) (optional accessory) to clamp the attachment rod.

f

Insert the drill chuck (13) into the tool chuck

(4) according to the instructions for installing

attachments. Turn the drill chuck to loosen the

clamps at the front-end of the drill clamp, and insert

the accessory bar (14) into the clamps and turn the

chuck in the opposite direction. You may also use the

drill chuck key to tighten the clamp.

Hammer Drilling (Fig.B)

f

For hammer drilling in masonry and concrete, set the

operating mode selector (3) to the position.

f

The drill bit has to be placed accurately onto the drill

hole position. After that, pull the switch for optimal

effects. Make sure the tool is in the correct position to

prevent the drill from deviating from the hole.

f

When the drill hole is clogged with debris or fine

powder, please don’t exert any more pressure. Tool

should be put in free-running state before removing

part of the drill bit from the hole. If repeated a few

times, the blockage in the hole would be cleared, and

normal drilling can resume.

Warning! When the drill bit hits cement or the steel rebar

in the cement, the tool may recoil dangerously. Please hold

the tool tightly in a balanced and stable position at all times

to pre- vent it from recoiling dangerously.