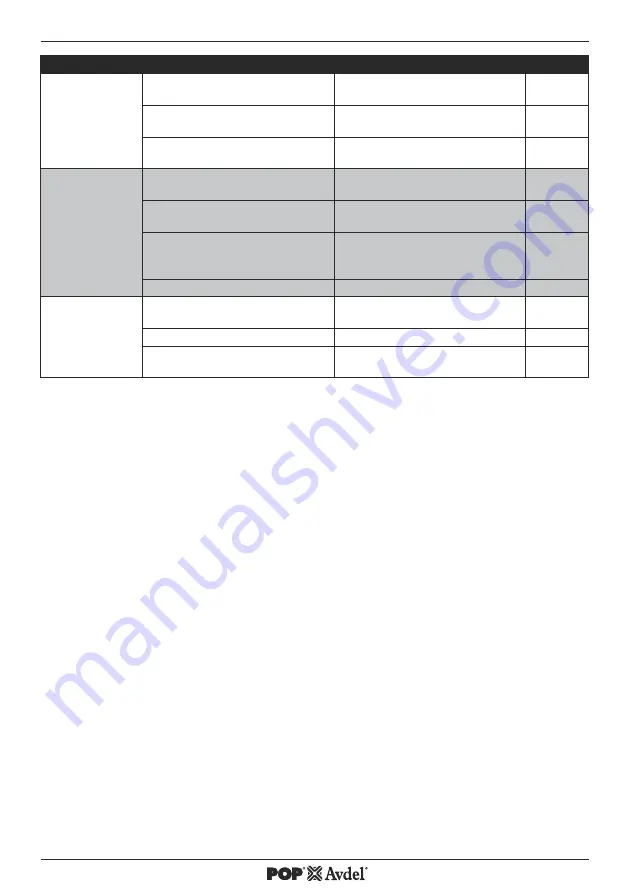

Symptom

Possible Cause

Remedy

Page Ref.

Slow cycle

Low air pressure.

Adjust air pressure to within

specification.

9

Build up of debris inside the Nose

Equipment (

1.

)

Service and clean Nose Assembly

(

1

.)

13, 15

Stem Collector (

3

) removed or not

fully attached.

Check Stem Collector.

14

Rivet stem does

not break

Low air pressure.

Adjust air pressure to within

specification.

9

Fastener outside tool capability.

Refer to Placing Tool Rivet Range &

Nose Equipment table.

11

Incorrect Nose Equipment (

1

) for

rivet.

Refer to ProSet Nose Equipment

Manual 07900-09414. Select and

install correct nose equipment

Low oil level or air in oil.

Prime tool.

16

Low vacuum

Stem Collector (

3

) removed or not

fully attached.

Check Stem Collector.

14

Stem Collector (

3

) full of stems.

Empty Stem Collector (

3

)

14

Low air pressure.

Adjust air pressure to within

specification.

9

Item numbers in bold refer to assembly drawings and parts lists on pages 2, 4, 5 and 6.

Other symptoms or failures should be reported to your local authorised distributor or repair centre.

8. General Safety Data

8.1 HYSPIN

®

VG32 OIL SAFETY DATA

8.1.1 First Aid

SKIN:

Unlikely to cause harm to the skin on brief or occasional contact but prolonged or exposure may lead to

dermatitis.

Wash skin thoroughly with soap and water as soon as reasonably practicable. Remove heavily contaminated

clothing and wash underlying skin.

Launder contaminated clothing.

ORAL:

Unlikely to cause harm if accidentally swallowed in small doses, though larger quantities may cause nausea

and diarrhea.

If contamination of the mouth occurs, wash out thoroughly with water.

Except as a deliberate act, the ingestion of large amounts of product is unlikely. If it should occur, do not

induce vomiting; obtain medical advice.

Take person to nearest medical centre.

EYES:

Unlikely to cause more than transient stinging or redness if accidental eye contact occurs.

Wash eyes thoroughly with copious quantities of water, ensuring eyelids are held open. Obtain medical advice

if any pain or redness develops or persists.

ENGLISH

22