5.5 SERVICE KIT

For an easy complete service, Stanley Engineered Fastening offers the complete Service Kit below.

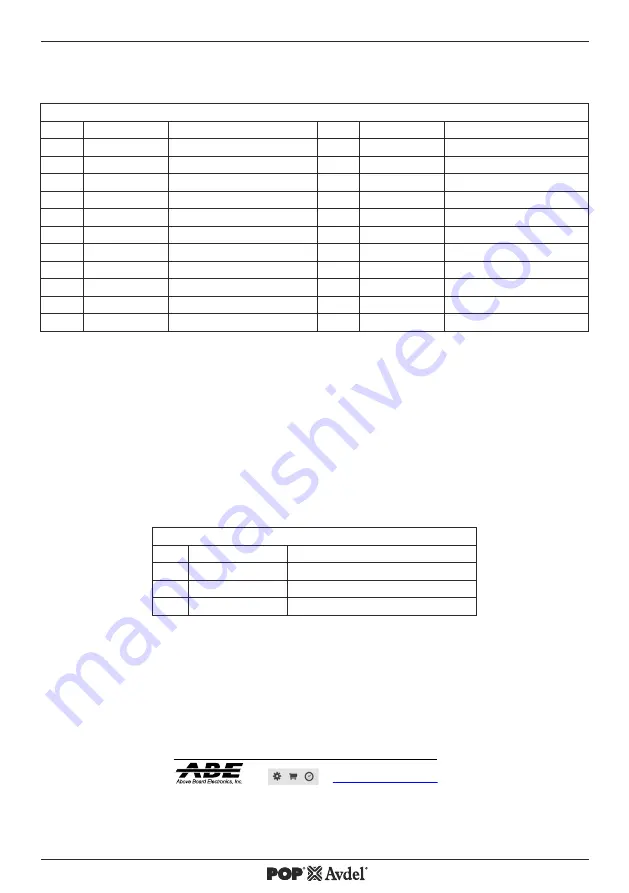

Service Kit 76003-99990

Item

Part Number Description

Item

Part Number Description

1

07900-00008 7/16 x 1/2 A/F Spanner

12

07900-00685 Insertion Rod

2

07900-00012 9/16 x 5/8 A/F Spanner

13

07900-00692 Trigger Valve Extractor

3

07900-00015 5/8 x 11/16 A/F Spanner

14

07900-00698 Stop Nut

4

07900-00158 2mm Pin Punch

15

07900-00700 Priming Pump Assembly

5

07900-00164 Circlip Pliers

16

07900-00706 Location Spigot Assembly

6

07900-00224 4mm Hexagonal Wrench

17

07900-00755 Grease - Molykote 111

7

07900-00351 3mm Hexagonal Wrench

18

07900-01085 Guide Tube

8

07900-00469 2.5mm Hexagonal Wrench

19

07900-01086 Piston Sleeve

9

07900-00670 Piston Bullet

20

07992-00020 Grease - Moly Lithium

10

07900-00672 Spanner Assembly

21

07992-00075 Grease - Molykote 55M

11

07900-00677 Seal Extractor

5.6 PRIMING

Priming is necessary after the tool has been dismantled and prior to operating. It may also be necessary to

restore the full stroke after considerable use, if the stroke has been reduced and fasteners are not now being

fully placed by one operation of the trigger.

Oil Details

The recommended oil for priming is Hyspin® VG32 available in 0.5l (part number 07992-00002) or one gallon

containers (part number 07992-00006).

Priming Kit

To enable you to follow the priming procedure below you will need to obtain a priming kit.

Priming Kit 07900-00688

Item

Part Number

Description

1

07900-00351

3mm Hexagonal Wrench

2

07900-00700

Priming Pump

3

07900-00224

4mm Hexagonal Wrench

Priming Procedure

IMPORTANT - DISCONNECT THE TOOL FROM THE AIR SUPPLY OR SWITCH OFF AT ON/OFF VALVE

ASSEMBLY 7. REMOVE NOSE ASSEMBLY OR SWIVEL HEAD COMPONENTS.

All operations must be carried out on a clean bench, with clean hands in a clean area.

Ensure that the oil is perfectly clean and free from air bubbles.

Care MUST be taken at all times, to ensure that no foreign matter enters the tool, or serious damage may

result.

ENGLISH

16

1-800-453-1692