OM600 ENGINE MECHANICAL 1B3-167

6. Coat the cylinder bore, connecting rod bearing journal,

connecting rod bearing shell and piston with oil.

7. Compress the piston rings with a tensioning strap (7).

Tensioning Strap 000 589 04 14 00

8. Insert the piston assembly into the cylinder with a wooden

stick (18).

Notice

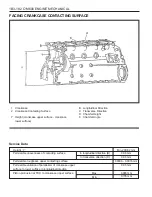

The arrow on the piston crown must point toward the front

of vehicle.

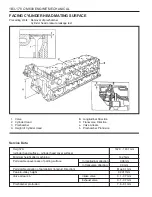

9. Insert the connecting rod bearing shells (9, 10).

Notice

Be careful of the difference in upper and lower bearing

shells and not to be changed.

10. Position the connecting rod bearings caps.

Notice

Position so that the retaining lugs are on the same side of

the connecting rod bearing(arrow).

11. Measure stretch shaft diameter (C) of the connecting rod

bolts.

Limit ‘C’

7.1mm

Содержание OM600

Страница 12: ...1B3 12 OM600 ENGINE MECHANICAL MAINTENANCE AND REPAIR ON VEHICLE SERVICE ENGINE ASSEMBLY ...

Страница 26: ...1B3 26 OM600 ENGINE MECHANICAL POLY V BELT ALIGNMENT INSPECTION Without Air Conditioner With Air Conditioner ...

Страница 51: ...OM600 ENGINE MECHANICAL 1B3 51 49 Remove the cylinder head 2 and gasket 3 OM661LA ...

Страница 145: ...OM600 ENGINE MECHANICAL 1B3 145 CHAIN TENSIONER 1 Chain Tensioner 80Nm 2 Seal Replace ...

Страница 171: ...1B3 172 OM600ENGINE MECHANICAL Oil Circulation ...

Страница 172: ...OM600 ENGINE MECHANICAL 1B3 173 Oil Filter a From Oil Pump b To Main Oil Gallery c To Oil Pan ...