74

A.0500.251 – IM-TL/13.00 EN (08/2009)

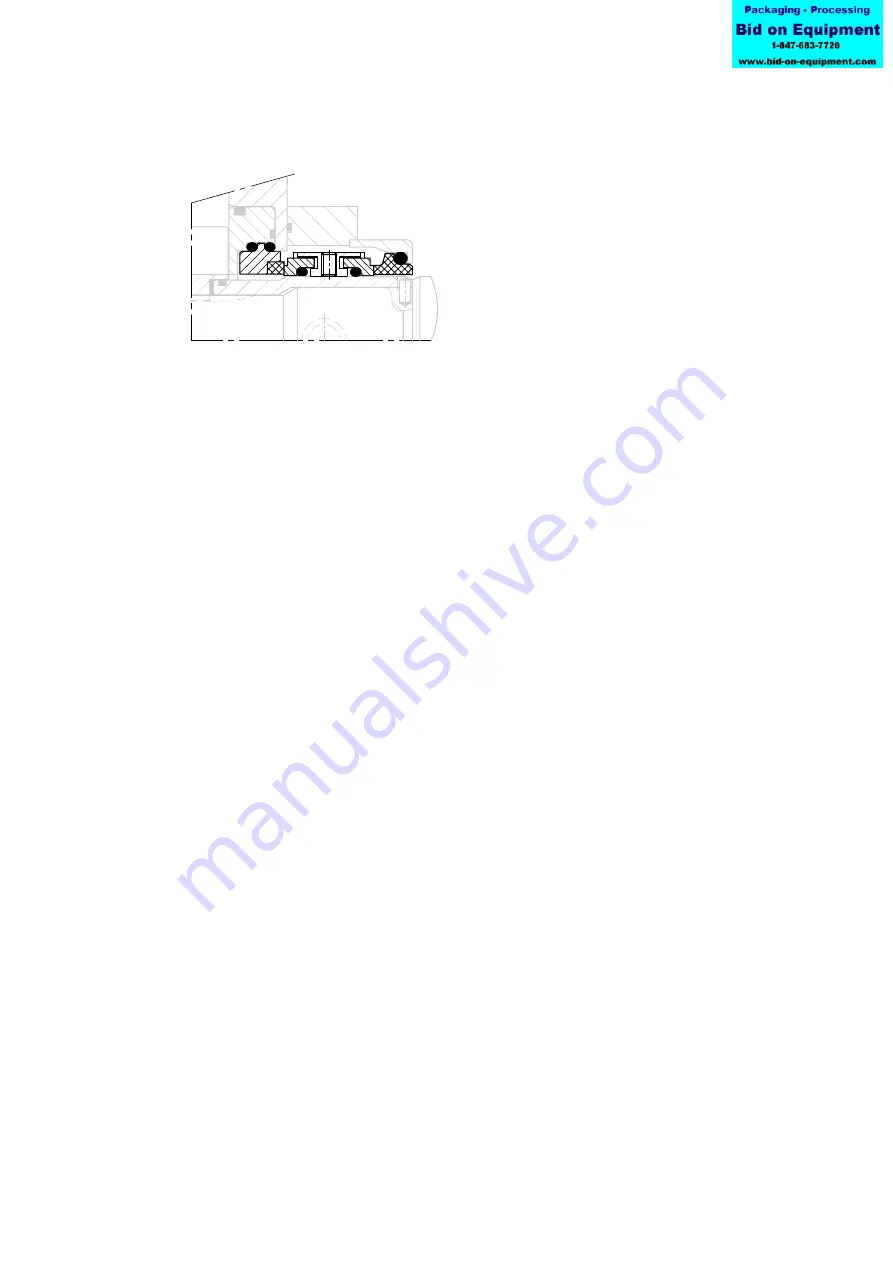

8.0 Double mechanical seal

8.1 General

Design

• Balanced mechanical seal.

• The product side stationary seal face is built into the seal cover which is assembled

in the rotor case from the front end and the atmopheric side stationary seal face is

built into the flush cover.

• Both stationary seal faces are locked against rotation by the friction forces of

O-rings.

• The spring loaded rotating seal faces are assembled into the driver which is locked

on the shaft sleeve by means of set screws. The seal faces are locked in the driver by

means of lips and slots.

• Suitable for two directions of rotation.

• Small seal faces prevents solidifying of medium between faces (reduced seal faces, so

called ‘‘knife edge seals’’ are available on demand).

• Quenched of flushed, pressurized or unpressurized.

Technical data

Materials:

DW2: SiC (Q1) - SiC (Q1) and

SiC (Q1) - Carbon (B) atmospheric side

DB2: SiC (Q1) - Carbon (B) and

SiC (Q1) - Carbon (B) atmospheric side

Materials of O-rings:

Fluorocarbon FPM

EPDM (E)

EPDM-FDA (E1 i.e.certified food quality)

PTFE lined (T)

Perfluor Chemraz

®

(C)

* Perfluor Kalrez

®

(K)

Temperature:

200°C or up to the temperature limit of the pump

Maximum pressure:

16 bar or up to the operating pressure limit of the pump

Hydrostatic test pressure:

25 bar (for mechanical seal)

Maximum pressure of

quench/flushing medium:

16 bar

Pressurised seal:

The pressure of quench/flush medium should be

1 bar/10% higher than the process pressure

Unpressurised seal:

Pressure is lower than or equal to the processing pressure

* Kalrez is a registered trademark of DuPont Performance Elastomers.