20

A.0500.251 – IM-TL/13.00 EN (08/2009)

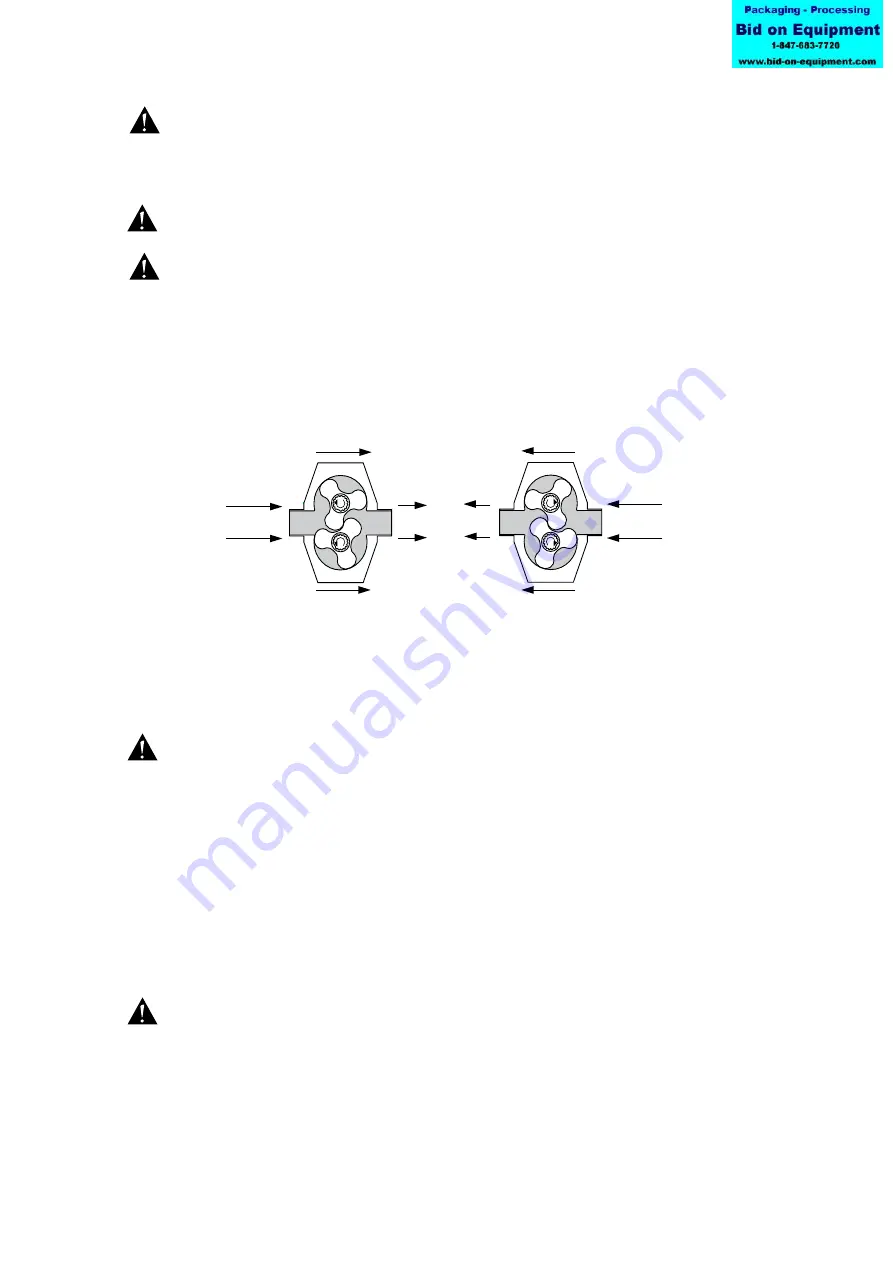

Direction of rotation

Suction

Discharge

Suction

Rotation

Rotation

2.5 Shutdown

When shutting the pump down the valves on the suction and discharge side must be

closed. Following precautions must be taken:

The power is shut off and the starting device locked so that the pump cannot be

•

started.

The pneumatic relief valve is purged.

•

The connections for the flushed mechanical seals are shut off and depressurised.

•

The pump and pipelines must be empty and de-pressurised.

•

See chapter “4.0 Disassembly and assembly instructions’’ before undertaking any work

on the pump.

2.6 Routine maintenance

Check the oil level regularly.

•

Change the oil once a year or every 3000 operating hours, whichever comes first.

•

For lubricant capacities and grades, see “Section 3.2’’.

•

Measure vibration and temperature, these factors can indicate bearing failure.

•

Control the quality of the oil. Change the oil if contaminated with water, etc.

•

Check that the valves are completely open on both inlet and outlet and that the

•

pipelines are free from obstructions. The TopLobe pumps are of the positive

displacement type and should therefore never be operated against a closed valve, as

this would result in pressure overload, damages on the pump and possibly damage on

the pump system.

Check that the drive shaft has the correct direction of rotation for required flow, see

•

figure below.

Before starting the pump, make sure that there is liquid on the suction side. This is

•

very important for pumps with unflushed product seals as these sealing arrangements

must never run dry.

Before operating the pump, briefly start and stop it to check the direction of rotation

•

and to make sure that there are no obstructions of the function. Keep a visual check

on the suction and discharge pressure gauges and monitor the pump temperature and

absorbed power.