21

A.0500.251 – IM-TL/13.00 EN (08/2009)

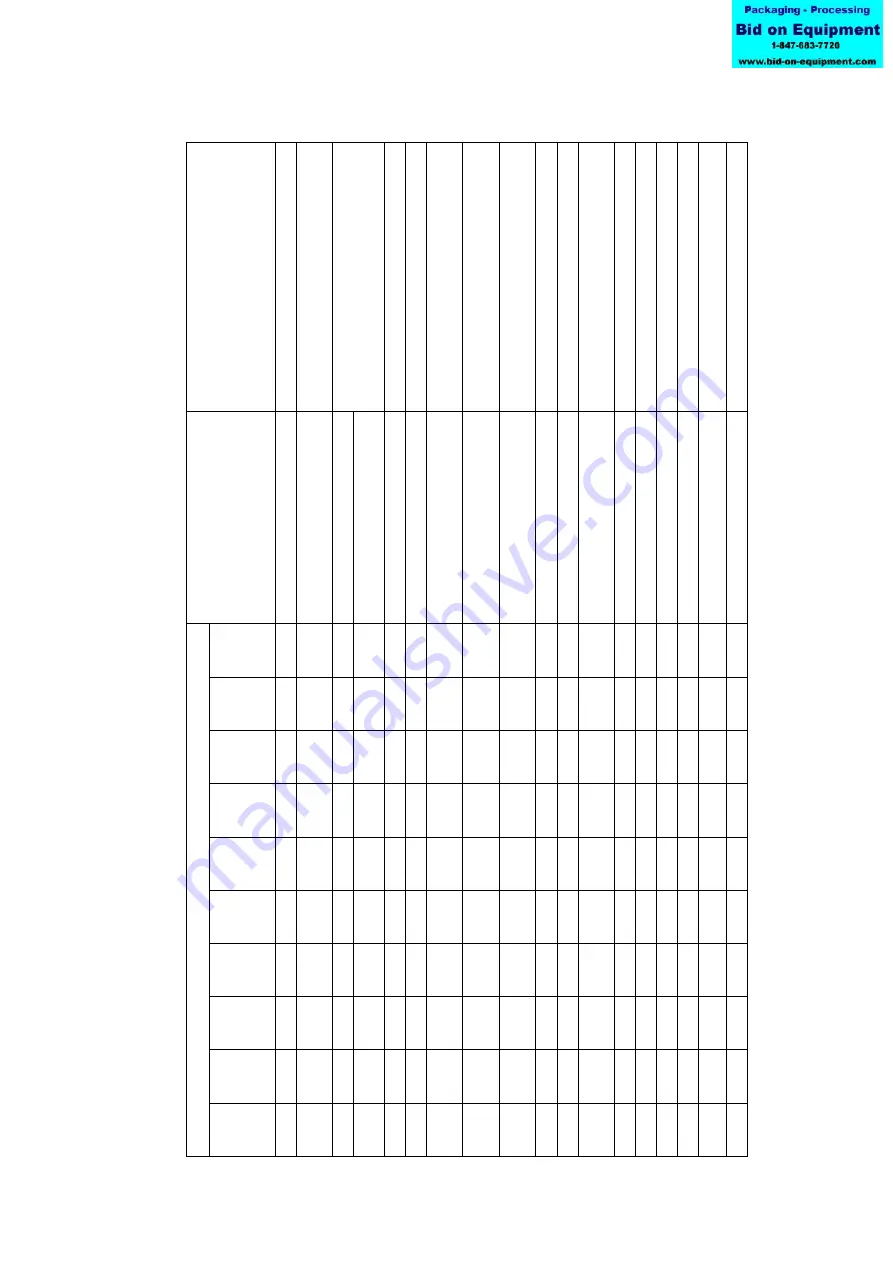

2.7 Trouble shooting chart

Symptom

Causes

Actions

No flow

Irregu-

lar flow

Low

capacity

Pump

over

-

heats

Motor

over

-

heats

Exes-

sive

rotor

wear

Exes-

sive

seal

wear

Noise/,

V

ibra-

tions

Seizure

Pump

stalls on

start up

•

Incorrect direction of rotation

Reverse motor

•

Pump not primed

Expel gas from suction line/pump chamber and

prime

•

•

•

•

Insufficient NPHS available

Increase suction line dia and static suction head

Simplify suction line and reduce length

Reduce pump speed and product temperature

•

•

•

Product vapourising in suction line

•

•

•

Air entering suction line

Remake pipework joints

•

•

•

•

Gas in suction line

Expel gas from suction line/pump chamber

•

•

•

Insufficient static suction head

Raise product level to increase static suction

head

•

•

•

•

Product viscosity too high

Decrease pump speed/increase product tempe-

rature

•

Product viscosity too low

Increase pump speed/decrease product tempe-

rature

•

•

•

•

•

Product temperature too high

Cool product/pumping chamber

•

•

Product temperature too low

Heat product/pumping chamber

•

•

•

•

Unexpected solids in product

Clean the system/fit strainer on suction side of

pump

•

•

•

•

•

•

•

Discharge pressure too high

Check for blockages/simplify discharge line

•

•

•

•

•

Rotorcase strained by pipework

Check pipe alignment/support pipework

•

•

Pump speed too high

Decrease pump speed

•

Pump speed too low

Increase pump speed

•

•

•

•

•

•

Seal flush inadequate

Increase seal flush to required pressure/flow

•

•

•

•

•

•

•

Bearing/timing gear wear

Replace worn components