10

If the upper band flows horizontely straight or up to 30 degrees only you have found

the suitable position. In case the band shows more than 30 degrees or turns round

the mast, the position is unsuitable. This test should be carried out at moderate wind

conditions and only gives an orientation. We recommend to do various tests to get a

better assessment. You need not do this test if the windgenerator is mounted far

away from obstructions.

Note:

Please note that the Silentwind generator can never be fully efficient

if it is not mounted in the prevailing wind direction or distracted by

obstructions. Therefore it is important to find a position that is not

obstructed by obstacles !

Having found the suitable position an appropriate mast with suitable equipment must

be chosen. The outer mast diameter must have 48mm and it should be inox steel or

alumine. Please also consider possible maintenance work. The mast with mounted

windgenerator should be able to take a wind blast pressure of 250Nm. Grounding of

the mast is highly recommendable. On boats you can use the central ground for mast

and engine. Ask a specialist for advice.

Once the mast is mounted you can start the relatively simple installation of the

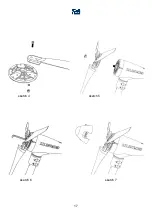

Silentwind generator. First connect the 3 CF blades to the assembly hub (see page

17, sketch 4) with the enclosed srews (page 18, sketch 9). The enclosed nylon discs

protect against electrolytic corrosion. The fastening torque is 7-8Nm equivalent to a

weight of 7-8 kilo on a 10cm long lever arm, upright to the lever arm.

If the fastening torque is too high, this will destroy or damage the blades. If the

fastening torque is not high enough, the blades can get lose. A wrong fastening

torque is a considerable safety risk.

Regularly control the fixation of the blades !

Before fixing the blades finally move the 3 blades in a position opposite to the

running direction. The running direction is clockwise looking from the front. Then fix

the blades as described above. The blades should not be out of balane then. The

blades have been balanced statically and dynamically. In case of damage of only one

blade you can buy a single one. When ordering one blade the purchasing department

needs the exact weight of the undamaged blades.

After connecting the blades the set is fixed to the generator shaft with the enclosed

srew nut and enclosed hexagon socket srew key. After that you snap the nose cone

into place on the assembly hub. (see page 17, sketch 5,6 and 7)

Содержание Silentwind

Страница 1: ...instructions for use installation manual SILENTWIND...

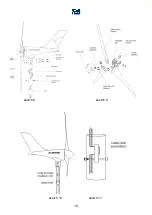

Страница 16: ...16 14 Attachment sketches sketch 1 sketch 2 sketch 3...

Страница 17: ...17 sketch 4 sketch 5 sketch 6 sketch 7...

Страница 18: ...18 sketch 8 sketch 9 sketch 10 sketch 11...

Страница 20: ...20 Notice...