NGW 300 / LGW 300 / GBW 300

9 Repair

901

9

Repair

9.1

General information

This section describes the permissible repair work when

the heater is disassembled. If there is any further disas-

sembly, any claim to a guarantee is extinguished. Only

Spheros replacement parts must be used for reassembly.

CAUTION

The ignition spark generator is operated with high voltage.

The following components must also be replaced when

the heater is in its installed state, if there is enough space

available:

•

Temperature limiter

•

Regulating thermostat

•

Control unit

•

Burner head

Before replacement, the heater must be switched off via

the main switch and the wiring harness connector in the

vehicle must be disconnected. Otherwise, there is a dan-

ger of death.

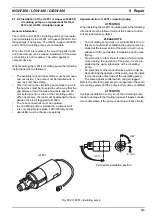

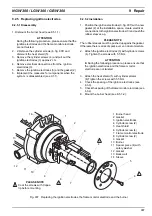

9.1.1 Measures for components when the

system is disassembled

ATTENTION

All sealing elements between the disassembled compon-

ents must be fundamentally eliminated and renewed. Be-

fore reassembly, the sealing surfaces must be cleaned

and sealant residue must be removed.

9.1.1.1 General visual inspection

•

Examine all components or damage (cracks, defor-

mation, wear etc.) and replace, if necessary.

•

Examine plugs and lines for corrosion, loose connec-

tions, crimping faults etc. and repair, if necessary.

•

Examine plugs for corrosion and connectors to make

sure that they are firmly attached and repair, if neces-

sary

9.1.1.2 Visual inspection of the combustion chamber

•

Examine the combustion chamber for scaling and re-

pair, if necessary.

•

Examine the welded seam for cracks and repair, if ne-

cessary.

PLEASE NOTE

Cracks in the welded seam of up to 80 mm in the

longitudinal direction at the end of the combustion

chamber are permissible.

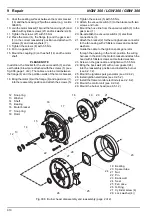

9.1.1.3 Visual inspection of the heat exchanger

•

Examine the exhaust gas routing in the heat exchanger

for damage and corrosion and repair, if necessary.

•

Examine the exhaust gas muffler in the exhaust con-

nector to make sure it is securely attached and for

thermal deformation and repair, if necessary.

PLEASE NOTE

Severe thermal deformations of the exhaust gas muffler

affects combustion.

•

Check the heat exchanger for external damage and

deformations etc. and repair, if necessary.

PLEASE NOTE

Severe deformations can compromise the coolant flow.

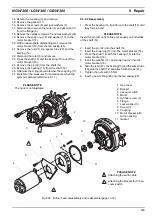

9.1.2 Implementation of modifications

PLEASE NOTE

Constant further development of the heaters means that

their performance is being optimised with the goal of

avoiding acciidents or malfunctions.

As a rule, heaters which are already in the field can be re-

trofitted. There are appropriate modification kits available

for this purpose.

Below are modifications which can be carried out in the

context of repair work.

•

Installation of the SG 1585 control unit as a replace-

ment for the SG 1578 control unit for the NGW 300

and LGW 300 (see 9.1.2.1)

•

Installation of the U 4851 or Aquavent 6000 S circula-

ting pump as a replacement for the U 4814 or U 4816

circulating pump (see 9.1.2.2)