NGW 300 / LGW 300 / GBW 300

8 Servicing work

803

PLEASE NOTE

The hose clamps must be tightened with the required

torque.

Care must be taken to bleed the cooling system before the

heater is used for the first time or after renewal of the

coolant. The heater and lines should be installed in such

a way as to guarantee static bleeding.

Inadequate bleeding can lead to a breakdown while the

heater is in operation, due to overheating.

Flawless ventilation is detectable, if the pump is working

virtually silently.

8.6.2 Connection to the vehicle’s gas system

For the NGW 300 version, gas must be withdrawn from

the tank or from the immediate vicinity of the tank.

Withdrawing gas from the filler line and at places where oil

and condensate can accumulate is not permissible.

Extraction must be performed in such a way that the least

amount of oil and condensate possible can enter the

supply line to the heating system’s gas pressure regulator,

(outlet at the top).

For the LGW 300 version, the gas must be withdrawn in

its gas phase in the tank.

Only the original Spheros hose may be used for the

gasline on the low pressure side between the gas

pressure regulator and the heater.

When installing the hose, icare must be taken to ensure

that there is a sufficient distance (min. 25 mm) from the

outer casing of the heater and/or it must be shielded to

protect it from from the heat.

The hose must not be kinked or twisted.

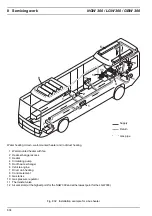

8.6.3 Combustion air supply

Combustion air is taken in via the inlet grille in the burner

hood.

Care must be taken not to suck in any exhaust gas.

If the heater is installed in an enclosed installation box, a

ventilation opening of at least 100 cm

2

is required.

The combustion air intake line can be extended with a

special version of the heater. The permissible dimensions

of the combustion air intake line are as follows for this

version:

–

Internal diameter: 60 mm

–

Maximum permissible line length: 3 m without an

exhaust extension

–

Maximum permissible bend: 450°

Under no circumstances may the combustion air be taken

from spaces which accommodate people. The

combustion air intake opening must not point in the

direction n which the bus is traveling. It must be

positioned so that it cannot become clogged with dirt or

snow and cannot suck in splashing water.

The combustion air intake opening must be designed in

such a way thata sphere with a diameter of 16 mm cannot

fit into it. However, the inlet cross-section may not be

restricted.

If the combustion air intake line cannot be installed so that

it slopesdownwards, then a water drain hole with a

diameter of 4 mm is to be made at its lowest point.

8.6.4 Exhaust gas line

The exhaust pipe opening may not point in the direction in

which the bus is traveling.

The exhaust pipe opening must be positioned so that it

cannot become clogged with dirt or mud.

Rigid pipes of unalloyed or alloyed steel with a minimum

wall thicknessof 1.0 mm or flexible piping of alloyed steel

only must be used as exhaust lines. The exhaust pipe is

secured to the heater using a clamping collar.

Permissible dimensions:

–

Internal diameter: 70 mm

–

Maximum permissible line length: 3 m

–

Maximum permissible bend: 270°

An exhaust extension is only possible if the combustion

air intake line has not been extended.