LPX-200

Industrial Imaging System

6-6

Chapter 6: LPX-200 Routine Upkeep and Care

Re-Filling the Tubehead

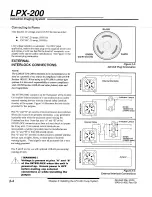

Use this procedure to re-fill the Tubehead in cases where the

gas pressure has dropped below 5 psi @ 70

°

F (refer to Figure

5-1 and 5-2).

1.

Remove the protective cover from the SF6 (sulfur

hexafluoride) cylinder (2). Remove the plug from

the cylinder valve (3) with a 3/8" allen wrench. The

cylinder valve outlet is left-hand threaded.

! WARNING !

Use extreme care while handling the

cylinder to preventing dropping it

after the protective cover has been

removed. Secure the cylinder to a

stationary post, or secure it against

tipping.

2.

Connect the SF6 charging regulator assembly (6), or

equivalent, to the SF6 cylinder valve.

NOTE:

The pressure regulator supplied with the optional

LORAD recharge kit is factory set to 70 - 75 psi @

70F, and locked with a hex nut on the adjustment

knob. However, due to spring tension aging, and/or

various ambient temperatures, this setting may need

to be updated.

3.

Connect the vacuum pump (10) and the Tubehead

(1) to the regulator assembly (6), using the hoses (8)

and (9) as shown in Figure 6-1.

4.

Leaving the SF6 gas cylinder valve (3) closed, open

the vacuum line (7) counter-clockwise.

5.

Start the vacuum pump and allow it to run for at least

20 minutes. The final vacuum indicated on the

regulator gauge should be at least 25" Hg.

6.

Close the vacuum line valve (7) and turn the vacuum

pump off. Open the SF6 cylinder valve (3) to its

fully open position (against its physical stop). Fill

the Tubehead until the gauge indicates 25 psi, then

close the cylinder valve.

7.

Open the vacuum valve and run the pump an

additional 10 minutes. Close the vacuum line and

stop the pump. Open the SF6 cylinder valve again

and fill the Tubehead to the pressure indicated on the

“

Pressure vs. Temperature

”

chart (Figure 6-2). When

the Tubehead is at the correct pressure, close the SF6

cylinder valve.

8.

Remove the charging hose connection at the

Tubehead, secure the gas cylinder, and replace the

protective cover. Re-check the pressure and inspect

the Tubehead for leaks.

Cleaning - Control Unit Air Filter

Clean the wire mesh air filter within the Control Unit each

month to remove dust, dirt, or debris collected during use.

Large accumulations of dirt can impede the flow of air

through the control unit chassis, which may result in damage

to circuit board components The following describes

removing and cleaning the Control Unit

’

s air filter.

1.

Remove the 4 screws that secure the filter cover to

the left side of the Control Unit.

2.

Pull the entire filter cover, with attached filter, out of

the Control Unit.

3.

Remove the 4 hex nuts that secure the filter to the

filter cover. Lift the filter off the cover.

4.

Remove any dirt, dust, or debris by washing the filter

in a solution of mild detergent and warm water.

5.

When complete, rinse the filter thoroughly with

clean, warm water. DO NOT use gasoline or other

solvents to clean the filter.

6.

Allow the filter to dry completely, or blow off any

remaining moisture with compressed air.

7.

Re-install the filter to the filter cover using the

previously removed hex nuts. DO NOT over tighten

or damage may occur to the filter.

8.

Insert the filter cover, with attached filter, into the

cut-out in the left side of the Control Unit. Secure

with the previously removed mounting scres.

Содержание LORAD LPX-200

Страница 1: ...LPX200 ...

Страница 4: ...ii Table of Contents LPX 200 Industrial Imaging System This Page Is Intentionally Blank ...

Страница 47: ......

Страница 49: ......

Страница 50: ......

Страница 51: ......

Страница 52: ......

Страница 53: ......

Страница 54: ......

Страница 55: ......

Страница 56: ......