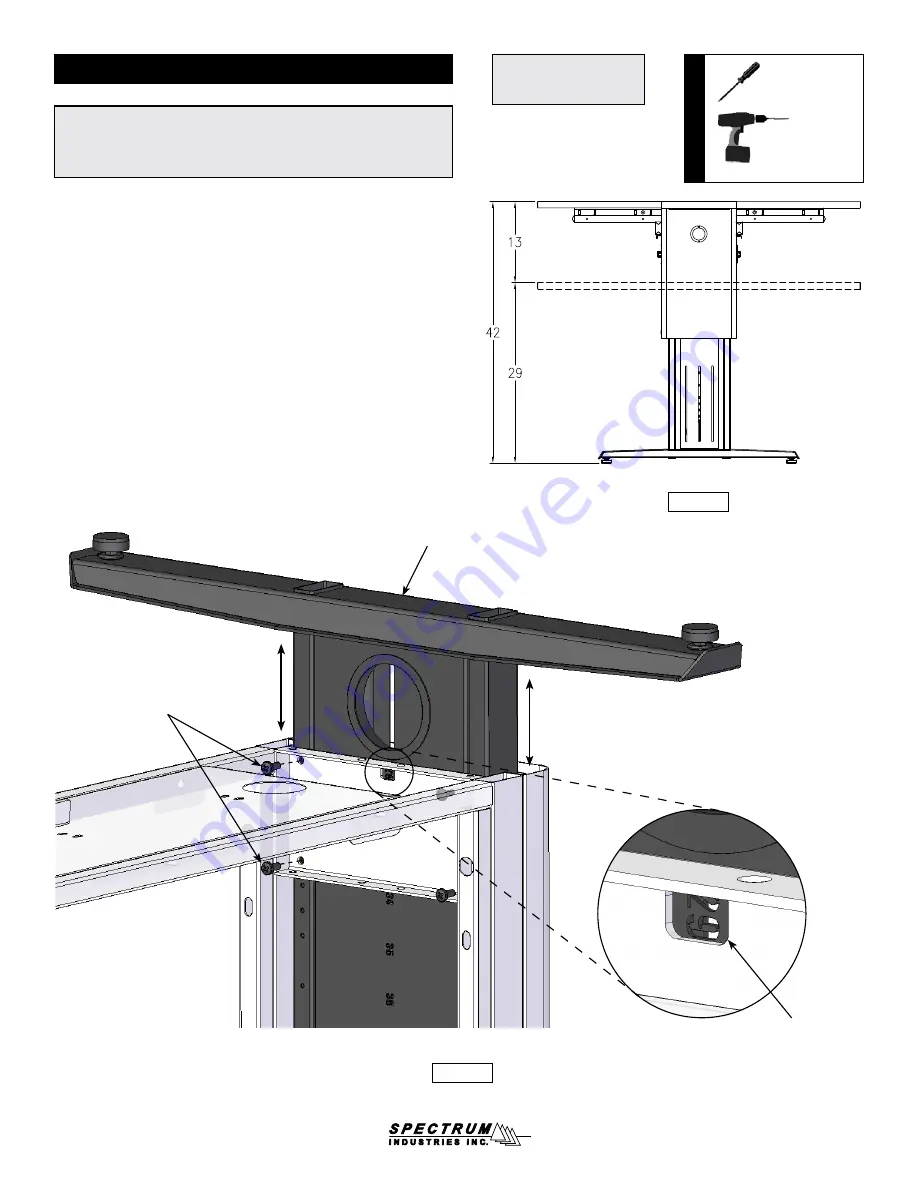

Set-and-go leg

1/4-20 x 5/8” PHMS

(4 required)

0115700R2 Page 5 of 17

Figure 3B

3. Adjust leg height (set-and-go legs only)

To adjust leg height:

1. Remove both side panels to provide access.

Figure 3B

.

2. Locate and remove the (4) 1/4-20 x 5/8” PHM screws that secure

the set-and-go leg. While these screws are removed, have a helper

support the detached leg.

3. Locate the height indicator window and slide the leg to the desired

height setting.

4. Replace the (4) 1/4-20 x 5/8” PHM screws and tighten securely.

5. Repeat on the second leg using the same height setting.

Note:

Tables with adjustable-height set-and-go legs can be adjusted to

have a worksurface height between 29”- 42” (in 1” or 2” increments).

Figure 3A

. The factory-set height is 29”H. Adjustment to the leg height

should be done while the table is still upside down on the pallet.

Height

indicator

window

Figure 3A

Note: If you have a table

with fixed or eLift legs,

proceed to step 4.

Phillips

screwdriver

Tools Required

Cordless drill

with long magnetic

Phillips driver

or

(best)