- 56 -

8.1 FREQUENCY OF CHECKS

The frequencies of maintenance operations are given as a

guideline and may vary depending on the type of service

and use of the machine, environment, temperature, climate

factors, etc.

- BEGINNING OF THE SEASON

Check the machine's general operation; this check should be

performed with the seed drill empty.

Run the turbine for a few minutes to remove any moisture

that may be present in the pneumatic circuit due to conden-

sation.

Check that the plastic parts are in good condition. Any de-

terioration of this material due to natural ageing or other

factors may cause damage to these machine components.

Check that the mechanical components are in good condi-

tion and are not rusted.

Clean the parts that are in contact with seeds or fertilizer, such

as hoppers and dispensers; if necessary, disassemble the com-

ponent.

Check that the signalling lights are working properly.

Check that the hydraulic circuit couplings and lines are not

leaking oil.

For models with a separate hydraulic circuit. Check the oil

filter. If it is saturated, change the oil and the filter (use ATF

DEXRON II oil - fill up to the dipstick level, approximately 45

litres). Check the pump's Valvoline oil level. If necessary, top

up to the level mark (SAE 90).

- PERIODICALLY

Make sure that there is no seed or fertilizer in the hoppers

before cleaning the seed drill with compressed air.

Check the condition of all the nuts and bolts. Especially the

parts that are in contact with the ground. Tighten all screws

and bolts.

Check that there are no traces of material, dust, etc. in the

dispensers or in the pneumatic circuits. The accumulation of

debris can damage the pneumatic system.

- END OF THE SEASON

Clean the machine thoroughly with pressurized air; make

sure that there is no seed or fertilizer in the hoppers and

pipes. Pay particular attention when cleaning parts that are

in contact with chemicals.

Adequately lubricate the machine's moving parts (see sec-

tion 8.4 GREASING AND LUBRICATION).

Paint any metal components that have lost their paint due

to wear and tear.

To properly store the machine, you can cover it with a tar-

paulin and store it in a dry place.

Thoroughly inspect all parts and replace any that are damaged

or worn.

It is recommended to place the machine under cover to protect

it from bad weather.

KEEP THE COULTER UNITS CLEAN; ACCUMULA-

TION OF SOIL, STONES, GRASS, ETC. MAY OB-

STRUCT THE SEEDING LINES.

THESE OPERATIONS MUST BE CARRIED OUT

WITH THE TRACTOR ENGINE COMPLETELY

STOPPED AND THE IGNITION KEY REMOVED

FROM THE IGNITION.

Careful maintenance of the machine ensures good perfor-

mance and long life.

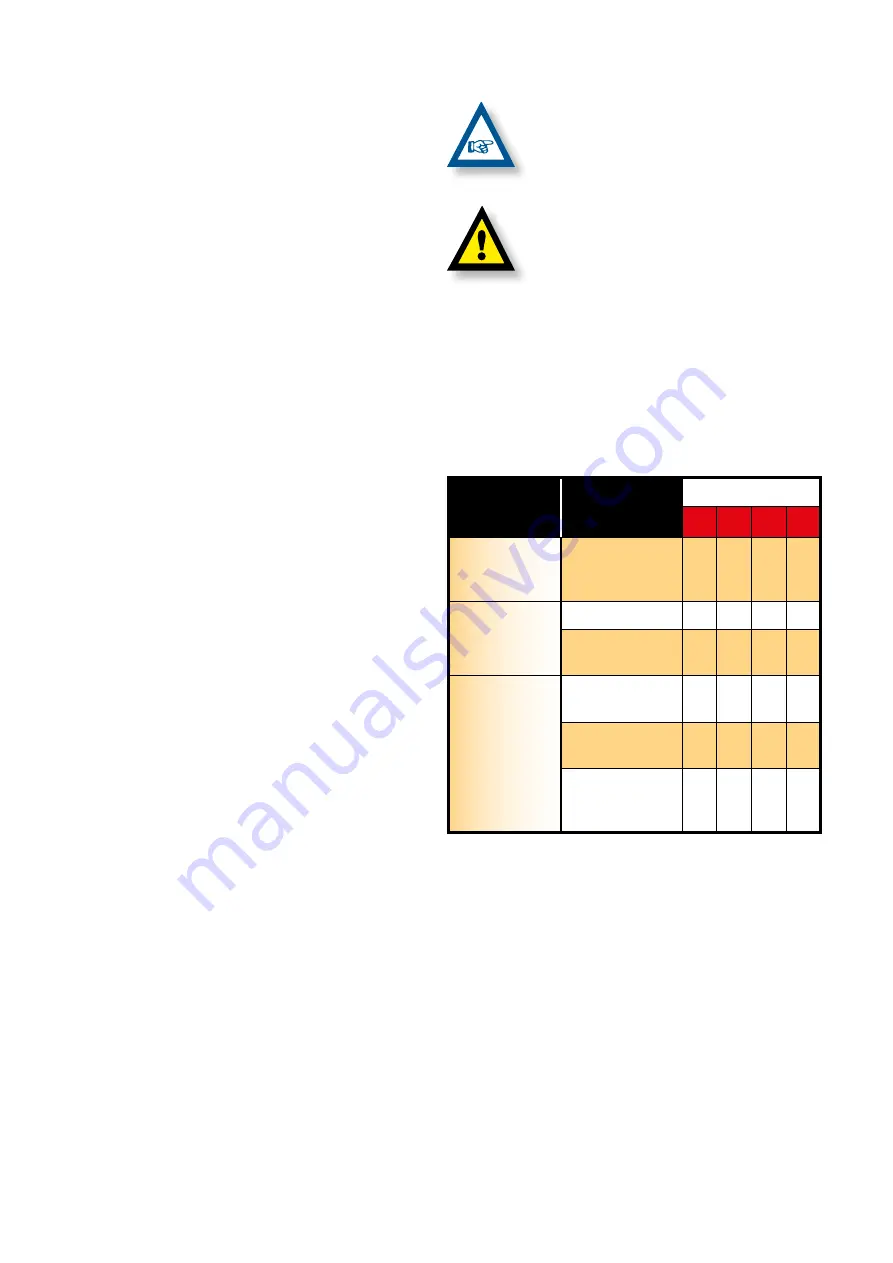

The following table shows the maintenance operations to be

carried out with their

approximate frequency

.

MAINTE-

NANCE

AREA

OPERATION TO

BE PERFORMED

HOURS

20 50 100 500

Machine parts

Grease all parts (con-

necting rods, axles,

hubs, etc.)

XX

XX

Wheels

Check tyre pressures

XX

Check the condition of

the floating wheel joints

XX

Mechanical

transmissions

Lubricate the chains

XX

Adjust the drive chain

tension

XX

Lubricate and grease

the transmission com-

ponents

XX

Содержание VESTA-2813 NS PLUS

Страница 75: ... 75 ...

Страница 76: ... 76 ...

Страница 77: ... 77 NOTES DATE NOTES ...

Страница 78: ... 78 DATE NOTES ...

Страница 79: ......