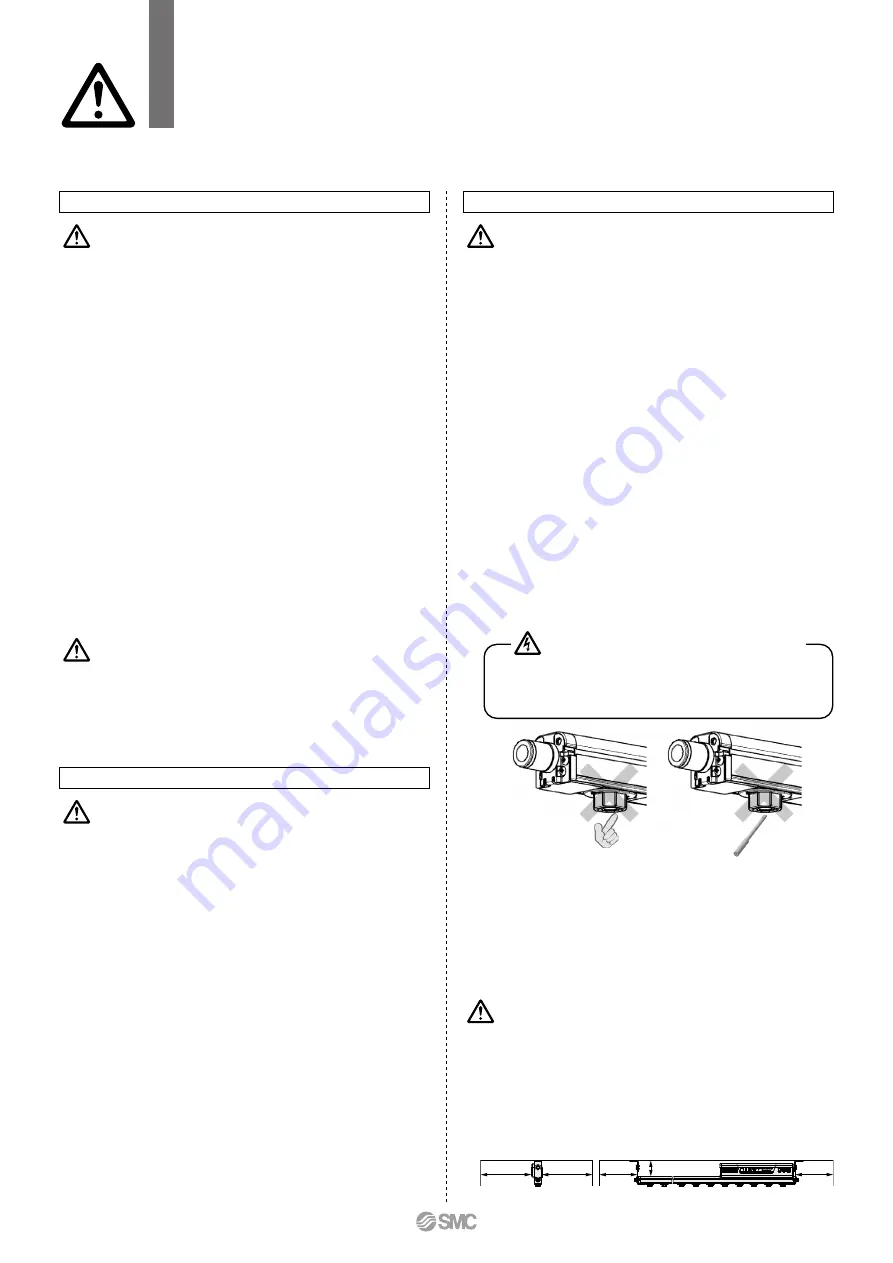

Emitters are under high voltage. Never touch them as there is a

danger of electric shock or injury due to an evasive action against a

momentary electrical shock caused by inserting foreign matter in

the emitter cartridge or touching the emitter.

IZS40/41/42

Series

Specific Product Precautions 1

Be sure to read this before handling the products.

Refer to the back cover for safety instructions.

Selection

Mounting

Caution

Caution

Warning

1. This product is intended to be used with general

factory automation (FA) equipment.

If considering using the product for other applications (espe-

cially those stipulated on Safety Instructions), please contact

SMC beforehand.

2. Use this product within the specified voltage and

temperature range.

Using outside of the specified voltage can cause a malfunction,

damage, electrical shock, or fire.

3. Use clean compressed air as fluid. (Air quality Class

2.6.3 specified in ISO 8573-1:2010 is recommended.)

This product is not explosion proof. Never use a

flammable gas or an explosive gas as a fluid and never

use this product in the presence of such gases.

Please contact us when fluids other than compressed

air are used.

This product is not explosion proof. Never use a flammable

gas or an explosive gas as a fluid and never use this product

in the presence of such gases. Please contact us when fluids

other than compressed air are used.

4. This product is not explosion-protected.

Never use this product in locations where the explosion of dust is likely to

occur or flammable or explosive gases are used. This can cause a fire.

1. Clean specification is not available with this product.

This product is not washed. When bringing into a clean room,

flush for several minutes and confirm the required cleanliness

before use. A minute amount of particles are generated due to

wearing of the emitters while the ionizer is operating.

3. Install the product so that the entire bar does not have

an excessive deflection.

For a bar length of 820 mm or more, support the bar at both

ends and in the middle by using brackets (IZS40-BM). If the bar

is held only at the both ends, self-weight of the bar causes

deflection, resulting in damage to the bar.

4. Avoid using in a place where noise (electromagnetic

wave surge) is generated.

Using the ionizer under such conditions may cause it to

malfunction or internal devices to deteriorate or break down.

Take noise countermeasures and prevent the lines from

mixing or coming into contact with each other.

5. Use the correct tightening torque.

If overtightened with a high torque, the mounting screws or

mounting brackets may break. Also, if under tightened with a

low torque, the connection may loosen. Refer to the operation

manual for details.

6. Do not touch the emitter directly with fingers or

metallic tools.

If a finger is used to touch the emitter, it may get stuck or an injury or

electrical shock may occur from touching the surrounding equipment. In

addition, if the emitter or cartridge is damaged with a tool, the

specification will not be met and damage and/or an accident may occur.

Mounting

Warning

1. Reserve enough space for maintenance, piping, and wiring.

Please take into consideration that the One-touch fittings for

supplying air, need enough space for the air tubing to be

easily attached/detached.

To avoid excessive stress on the connector and One-touch

fitting, please take into consideration the cable and tube

minimum bending radius and avoid bending at acute angles.

Wiring with excessive twisting, bending, etc., can cause a

malfunction, wire breakage or fire.

Minimum bending radius: Power supply cable: 38 mm

Transition wiring cable: 38 mm

Sensor cable: 25 mm

*

Shown above is wiring with the fixed minimum allowable

bending radius and at a temperature of 20

°

C. If used under

this temperature, the connector can receive excessive

stress even though the minimum bending radius is

allowable. Regarding the minimum bending radius of the

tubing, refer to the operation manual or catalog for tubing.

2. Mount this product on a plane surface.

If there are irregularities, cracks or height differences, exces-

sive stress will be applied to the housing or brackets, resulting

in damage or other trouble. Also, do not drop or apply a strong

shock. Otherwise, damage or an accident can occur.

7. Do not affix any tape or seals to the body.

If a tape or seal contains any conductive adhesive or reflective paint, a

dielectric phenomenon may occur due to the generated ions, resulting

in electrostatic charge or electric leakage. Avoid using such tape and

seals as it will not only cause difficulties in maintaining the performance

of the product, but may also result in the failure of the product.

8. Installation should be conducted after turning off

the power supply and air supply to the body.

Caution

Danger High Voltage

1. Do not install the IZS4

series in a location where walls or

structures are within the range shown in the following figure.

If structures including walls or conductive items are located close

to the unit, the generated ions will not effectively reach the object,

and the specification may not be satisfied, or cause failure of the

product or electric shock due to dielectricity or electric leakage.

Install the product according to the dimensions shown in the

following figure, keeping away from structures or conductive items.

Unit: mm

200

200

150

60

150

27