20

6. Maintenance

Maintenance must be considered a set of procedures with the purpose to keep the

equipment best opera

ti

ng condi

ti

ons, therefore increasing the equipment life and safety.

* Cleaning – check item 3,3 Cleaning.

* Wiring - Check all wires regarding deteriorate condi

ti

ons as well as all electric contacts

(terminals) regarding

ti

ghtening and corrosion.

*Contacts – ON/OFF switch, emergency bu

tt

on, reset bu

tt

on, electronic circuits etc ,

check the equipment in order to assure that all components are correctly working and the

equipment opera

ti

on is normal.

* Installa

ti

on – make sure the installa

ti

on followed item 2.1 instruc

ti

ons.

* Equipment life span: 2 years if normal working

ti

me is performed.

1 – Each month check:

- Check the electrical installa

ti

on

- Measure the voltage at the socket

- Measure the working current and match it with the nominal current

- Check the

ti

ghtening of all electric terminals to avoid bad contacts

- Check electric motor sha

ft

clearance

- Check the wiring for overea

ti

ng, insula

ti

on failures and mechanical damages.

2 – Each three month checks:

- Check electrical components such as ON/OFF switch, emergency bu

tt

on, reset bu

tt

on,

electronic electric circuits , overea

ti

ng, insula

ti

on failings, or mechanical damages

- Check bearings clearances

- Check retainers, O’rings, V’rings and other seals

5

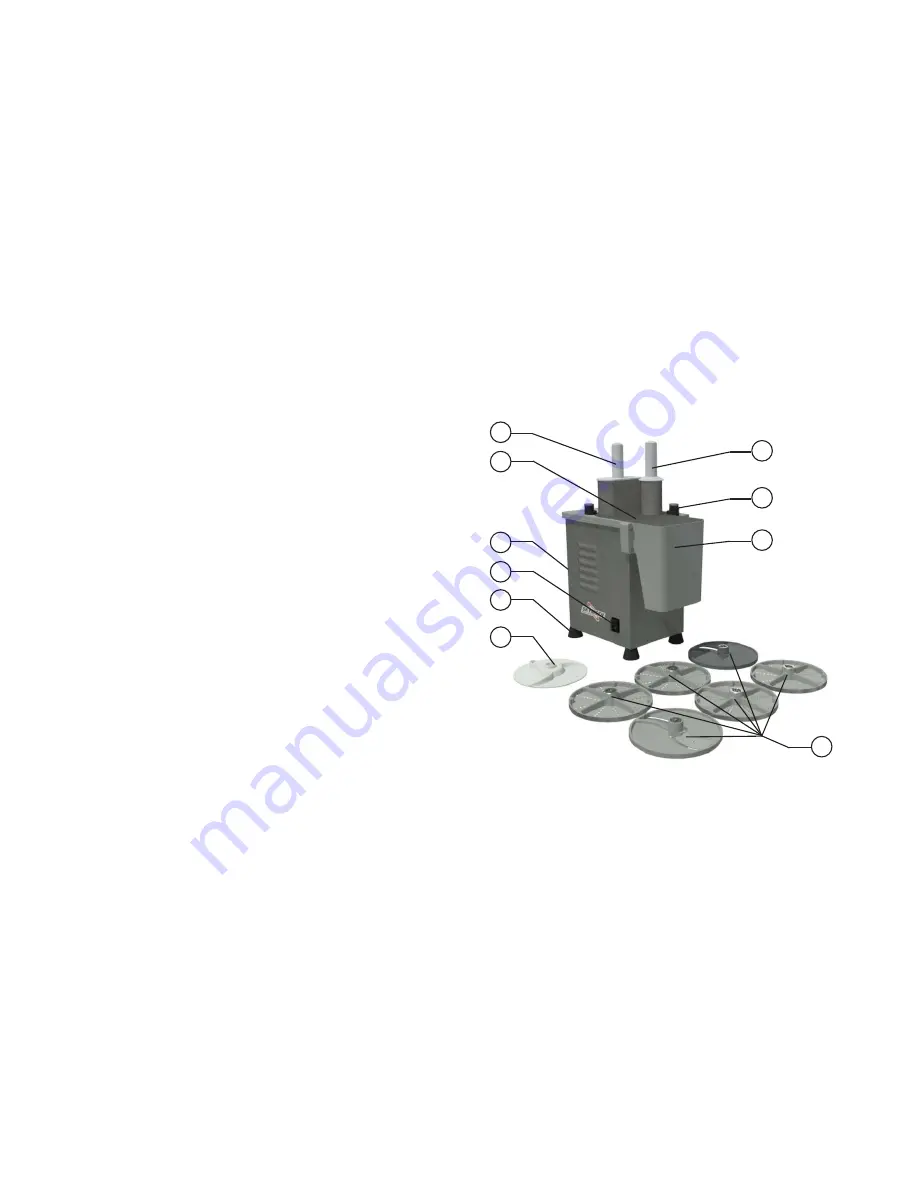

1.2 Main Components

All components are made with carefully selected materials, in accordance with Siemsen

experience and standard tes

ti

ng procedures.

PICTURE 01

01 – Chamber Lid

02 – Round Stumper

03 – ON/OFF Switch

04 – Plate Chamber

05 – Oblong Stumper

06 – Lid Fastening

07 – Motor Housing

08 – Plates

09 – Feet

10 – Expeller Dish

06

04

02

08

05

07

03

09

10

01