18

SerVice anD inStallation Manual

5. A password may be required; enter the upload

password given by LSI technical support and press

enter

.

6. Transfer progress is indicated on screen.

7. When the transfer is done, “

t

ranSFer

SucceSSFul

” will appear. Press

enter

and then

unplug the USB key. The LMS will restart by

itself.

4.3

4.3

data Logger viewer

data Logger viewer

The data logger viewer is a software application

used to display the data logger log file on a

personal computer (PC).

The data logger viewer converts the log file to a text

(binary) file, and then displays the contents. Two

reports can be produced and transferred to Excel,

the full report and the wind speed report.

4.3a installation on a pc

Install the CD in a CD-ROM drive. The interactive

installation process should start automatically within

30 seconds; if not then:

1. Click Start.

2. Click My Computer.

3. Double-click on the CD-ROM drive.

4. Double-click on

setup.exe

.

5. Complete the installation as instructed on

screen.

4.3b Quick Start

1. Start the data logger viewer application.

2. Open the log file (see section 4.1b). Only

.dtl

files generated by the LMS data logger can be

displayed.

4.3c Full report

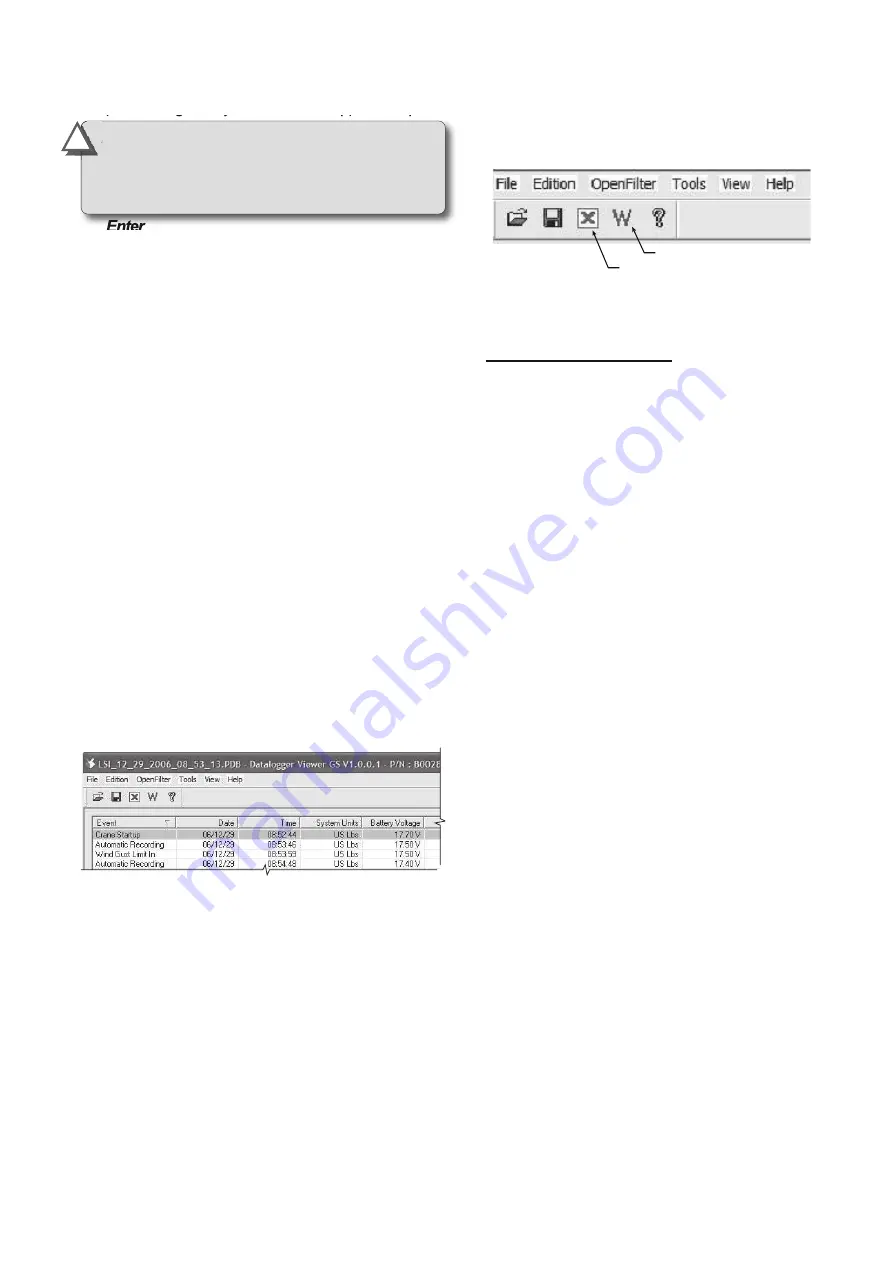

To export the full report to Excel, click on the Full

Report button in the tool bar.

table: Full report column headings

Column

description

Event

..................Record trigger*

Date

....................Event date stamp.

Time

....................Event time stamp.

System Units

......Length units (metric or US) and weight

units at the time of the event.

Battery Voltage

..Display power supply voltage at the

time of the event.

Temperature

......Internal temperature of the display.

Firm. Version

......Display firmware version at the time of

the event.

Sensor # 1

..........Sensor type: the sensor number

corresponds to the sensor list

programmed in the LMS.

Sensor Status

....Sensor was active or inactive at the

time of the event.

Sensor Battery

..Sensor battery level.

Value

..................Sensor value.

* Examples: Pipelayer start-up, sensor alarm. The

beginning and end of sensor alarms are indicated as “in”

and “out”: examples: “overload in”, “overload out”.

Full Report button

Wind Report button

Figure: Data logger Viewer tool bar

Figure: excerpt of a full report in Data logger Viewer

IMPORTANT!

Contact LSi technical support

to get the upload password;

this password

changes according to the random number indicated

on the LCD

. Please provide the random number.

!

!

SkyAzul, Equipment Solutions

www.skyazul.com

301-371-6126

Содержание Trimble/LSI GM820

Страница 1: ...Trimble LSI GM820 Volvo With GS820 Display and Wireless Sensors Installation and Service Manual...

Страница 2: ......

Страница 4: ......

Страница 28: ......

Страница 29: ......