由於縫製作業的具體情況,有時不得不靠近機器轉動的零部件進行操作而有可能接觸到轉動零部件,因此實際操作機

器的操作員和維修保養的維修人員,必須在事前仔細閱讀有關安全的注意事項,充分理解內容之後再進行操作。此有

關安全的注意事項中記述的內容有的不是使用者購買的商品規格的內容。

另外,為了能讓用戶充分地理解使用說明書以及產品的警告標籤,特將警告表示分為如下種類。請充分瞭解這些內容,

並遵守指示的要求。

經理及主管有責任讓他們的同事在操作前完全理解

。

沒有遵守本手冊中列出的說明可能導致嚴重傷害甚至死亡

,

以及財產損失

。

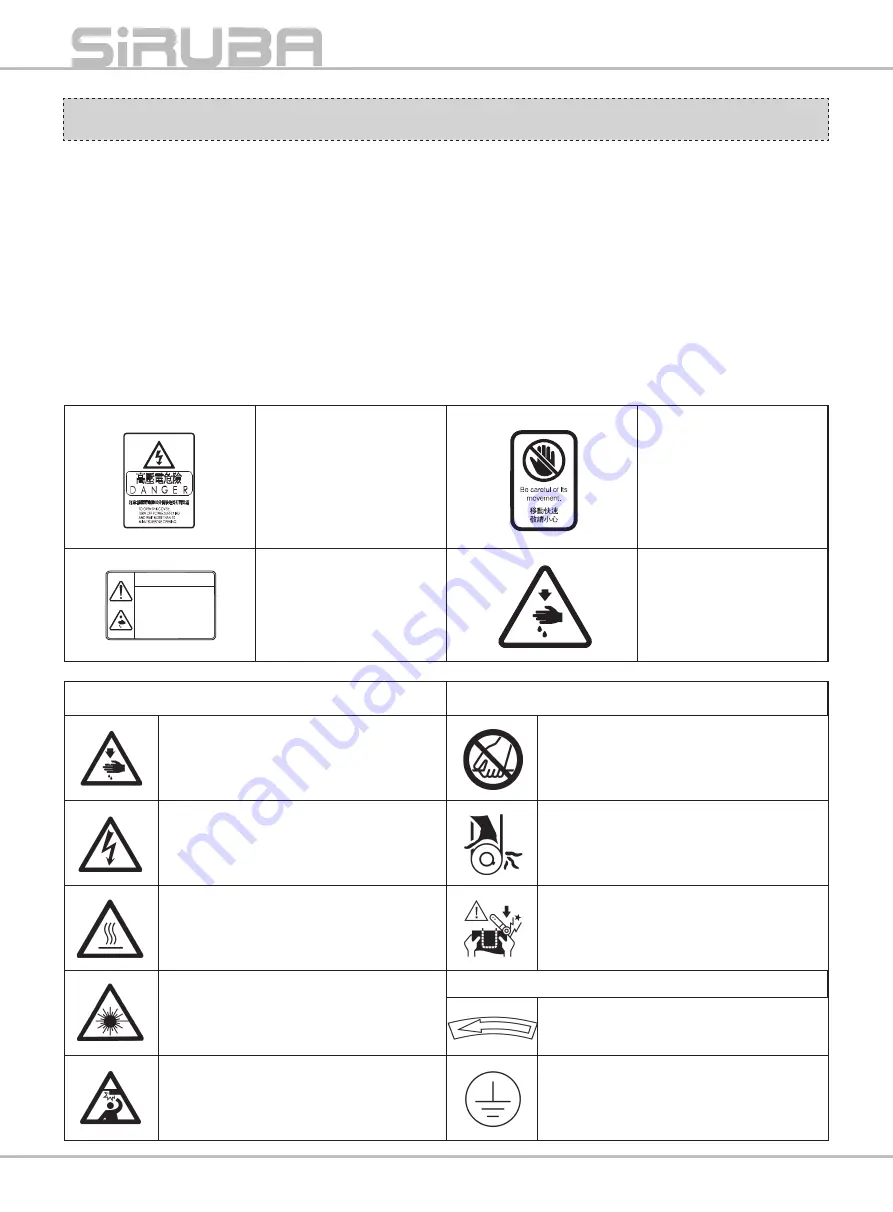

警告圖示表示和指示標籤的說明

一般安全聲明

高壓部位

務必關閉電源

10

分鐘後

始打開電控箱蓋子

高速運動部位

謹防工傷事故

高速運動部位

謹防工傷事故

高速運動部位

謹防工傷事故

CAUTION

機械作動部份請注意裝上

保護裝置

穿線、換線、調整、清潔

時請注意關閉電源.

Moving parts may cause in jury.

Operate with safety devices.

Turn off main switch before

threading, changing bobbin and

needle, cleaning etc.

警告圖標表示

警告圖標表示

有接觸轉動部,造成受傷的危險。

作業時拿縫紉機的話,有讓手受傷的危

險。

有接觸高電壓部,造成觸電的危險。

有捲入皮帶,造成受傷的危險。

有接觸高溫部,造成燙傷的危險。

觸摸了鈕扣傳送器,有受傷的危險。

如果直接目視鐳射的話,有傷害眼

睛的危險。

指示標籤

指示正確的轉動方向。

有頭部接觸到縫紉機的危險。

指示地線的連接。

Содержание BH9820

Страница 1: ...BH9820 OPERATION MANUAL...

Страница 2: ......

Страница 3: ...ENGLISH ENGLISH...

Страница 10: ...2 Effective standard for product QCYXDK0004 2016 Computerized Control System for Industrial Sewing Machine...

Страница 49: ...41 6 4 MASC511 Eyelet Buttonhole Machine System Diagram...

Страница 50: ...viii...

Страница 51: ...i...

Страница 53: ...5 1 1 2 3 4 2 1 2 3 3 1 2 3 4 1 2 3 5 EMG 1 EMG 2 3 4...

Страница 54: ...6 7 8 9 1 1 2 3 2 1 2 3 3A 1 2 3B 1 2 30mm 3 4 3C 1 2 3D 1 2...

Страница 55: ...4 1 2 3 4 5 1 2 3 4 5 6 6 1 2 3 7 1 2 3 4 5 6 7 8 8 1 2 10 3 4 5 35 35 85 5 6 7 8 9...

Страница 58: ...2 1 3 1 4 1 5...

Страница 59: ...3 2 2 1 1 2 3 4 U...

Страница 60: ...4 2 2 MASC511 MASC511 0 0 01 02 A EB012 B 1 2 3 A B...

Страница 61: ...5 2 3 2 3 1 1 1 2 3 4 5 6 ENTER 7 RESET 8 6 9 5 10 THREAD 11...

Страница 62: ...6 12 13 14 15 2 3 2 20 P01 P20 P01 P20 P01 P20 1 1 P01 P02 P20 C1 C2 C9...

Страница 66: ...10 2 4 1 2 3 4 2 P01 P02 P20 C1 C2 C9 P01 5 6...

Страница 67: ...11 6 2 4 2 7...

Страница 68: ...12 2 4 2 6 0...

Страница 69: ...13 2 5...

Страница 70: ...14 2 6 FRONT BACK FRONT BACK 2 7 Z 180 X Y Z 1 1 RESET 2 2 3 180 X Y Z...

Страница 71: ...15 3 3 1 MASC511 1 2 3 4 5 6 2 2 P01 P02 P20 C1 C2 C9 7 8...

Страница 72: ...16 3 2 1 2 3 4 5 2 2 P01 P02 P20 C1 C2 C9 6 7...

Страница 73: ...17 1 5 1 8...

Страница 74: ...18 7 3 3 3 3 1 1...

Страница 75: ...19 3 3 2 2 RESET 3 3 3 2 RESET 3 4 5 5...

Страница 76: ...20 3 4 P01 P20 9 C01 C09 9 S1 S9 P 3 P01 1 P03 C1 C1 C S1 S2 S3 S4 P01 P01 P01 P03 1...

Страница 77: ...21 C1 P01 P02 P20 C1 C2 C9 P01 2 3 4 S1 5 S1 5 P01 P01 6 P P S1 5 3 S2 4 5 S2 S1 P01 S3 S1 P01...

Страница 78: ...22 3 S4 S4 6 P03 7 6 P03 P03 1 C...

Страница 79: ...23 4 4 1 1 2 3 4 5...

Страница 80: ...24 4 2 4 3 U 1 1 U update mControl update 2 U 3...

Страница 81: ...25 2 1 U update LCDpanel update 2 U 3 4 4 U...

Страница 82: ...26 U U001 1 2 0 1 2 0 2 1 2 U051 1 1 0 800 50ms 0 U056 0 OFF 1 ON 0 1 1 0 U057 0 OFF 1 ON 0 1 1 0...

Страница 88: ...32 4 6 U 1 2 3 4 5...

Страница 91: ...35 M 005 M 006 M 007 M 008 M 009 M 010 M 011 M 012 5 3 01 02...

Страница 92: ...36 6 2 6 1 4 6 2...

Страница 93: ...37 6 3 MASC511...

Страница 94: ...38 6 4MASC511...